MYCRONIC PI Pico 3D SPI Machine

Highly accurate 3D inspectionPatented Z-referencing technology for paste volume measurement.

Superior repeatabilityMulti-frequency, multi-pattern moiré and patented dual Z-axis motion.

Auto-programming SPIMachine learning algorithms, facilitates for operators of all experience levels.

High accuracy and repeatability 3D SPI with auto-programming

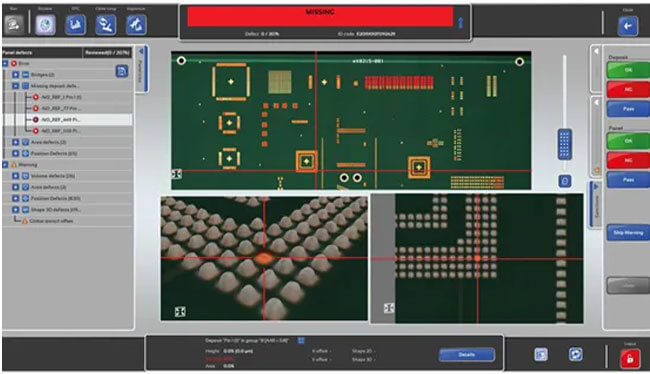

Clear and simple inspection control

Clarity and simplicity are words rarely associated with the complex process of solder paste inspection (SPI). But the PI series changes this. Thanks to an intuitive touchscreen interface, it can easily be set up and run by anyone with just an hour of training. Calibration requires only the touch of a button. The machine programs itself after a single bare board scan. And performance remains consistent across SMT lines — with no fine tuning.

Measure paste volume with unmatched accuracy and repeatabilityZ-referencing is the key to accurate solder paste inspection. This is why, rather than referencing just a small cropped area around the pads, the PI series captures hundreds of references across the ultra-large 3D field of view. As a result, you always know the exact volume of paste deposited on even the smallest pads. Regardless of board warpage, your measurements remain accurate in all types of real production environments, with no false calls.

Take control over the print process

To further enhance your process control, the PI series utilizes automatic pad grouping by area aperture ratio (AAR). This allows you to continuously improve your process and set tolerances independent of products. It also provides extra-large 3D review images for easy diagnostics. Whether you’re using the built-in closed-loop function to improve yields or monitoring your process in real-time with MYPro Live, the PI series gives you total control over the print process to ensure better products and higher yields with every batch. To keep track of your performance over time, MYPro Analyze helps you report and monitor your progress, generating useful insights and trend analyses.

Stable and accurate Z-reference

PI series patented Z-referencing method leverages the entire textured 3D board information, rather than just cropped images around the pads, to define a stable and accurate Z-reference.

MYPro Analyze

Monitor your process in real time with MYPro Analyze: accurate production data help you optimize your performance and give you meaningful information to further improve and maximize first-pass yield.

Synergy with MY700 Jet Printer

Inspects jet printed deposits with the same virtuosity: PI series 3D SPI handles jet-printed PCBs with the same performances and programming process as for screen-printed boards. The synergy with Mycronic MY700 Jet Printer enables inspection of all types of deposit shapes and volumes, whatever the type of solder paste used. And when every board counts, a repair loop enables a PI series 3D SPI to communicate any insufficient paste information to the MY700, so defects are corrected without having to wash and reprint the PCB.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky