Heller 1913 MK5 SMT Reflow Oven

Best value SMT Reflow Oven in the market. Designed for Low Cost of ownership.

1.Suitable Heating Technologies For Lead-Free Wave Soldering Processes

2.Temperature Adjustment Range: 60o-350o

3.Max Temperature: 450°

4.Lifetime Guarantee In Motors And Heaters

5.26 Heating Modules (13 Top Modules, 13 Bottom Modules)

6.Standard PCB Size: 508 Mm

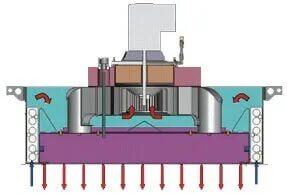

7.Forced Hot Air Convection

8.Maximum Conveyor Speed: 188 Cm/Min

9.Temperature Accuracy: +/- 1°

10.3 Cooling Zones

11.Option to operate with nitrogen

12.Dimenions (mm): 5.890 (L) x 1.370 (H) 1.600 (H)

13.Weight (kg): 2.900

14.Electrical Data: AC 380 (50/60 Hz,3 Phase)

15.Optimum Power Consumption : 12 kW

16.Nitrogen Consumption (for Nirogen Models) : 500 - 700 SCFH, Minimum Oxygen Value 10 -25 PPM

The ultimate high volume Surface Mount Technology production solution with belt speeds up to 1.4m/min to accommodate the fastest pick-and-place systems delivering the highest levels of repeatability with the lowest delta Ts.

Highest Yields and Tight Process Control

- The most efficient heat transfer from extra high volume, high-velocity, heating modules, producing heater module response of less than one second to temperature changes of less than 0.1ºC, thereby maintaining profile integrity for heavy board loads.

- Wide process window for “universal profiling” – allows many different boards to be run on a single temperature profile

- Advanced 5 thermocouple PCB profiling and process parameter logging capability with the capacity to store up to 500 temperature recipes and 500 profile graphs

With a high-capacity, 26-inch wide heater module, the 1900 MkV Series reflow oven machine system offers unmatched flexibility in pcb board handling. The oven may be fitted with an adjustable single-rail edge hold conveyor/mesh belt combo, to carry even the largest boards or multi-board panels (up to 20 inches wide) through the oven.

Features & benefits of MK5 series SMT reflow oven

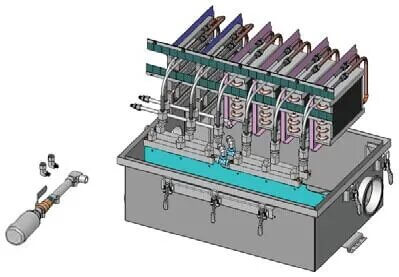

New Flux System Virtually Eliminates Maintenance

This new flux collection system traps the fl ux in a separate collection box with easy to remove plates. As a result, the oven tunnel is kept clean – thus saving time consuming P.M. A collection jar captures the fl ux and can be removed while the oven is running for the ultimate in time savings!

Enhanced Heater Modules

Enhanced flow heater modules with 40% larger impellar, blanket the PCB with heat for the lowest delta Ts on the toughest boards! Additionally, the Uniform Gas Management system eliminates net flow which results in nitrogen consumption reductions of up to 40%!

Ultra-Parallel Conveyor System

Four (4) lead screws ensures the tightest tolerances and parallelism – even on boards with 3mm clearance at the edges!

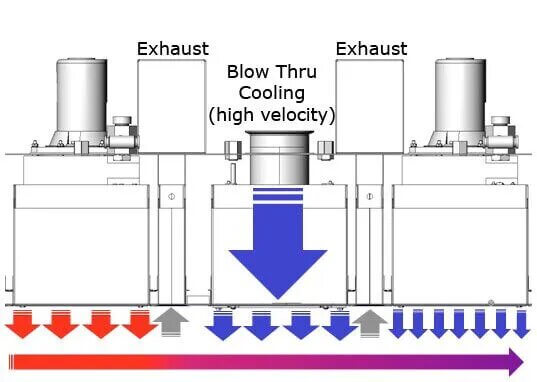

Fastest Cooling Rates

The new Blow Thru Cooling module provides cool rates of >3º C/sec – even on LGA 775! That rate meets even the most demanding lead-free profile requirements!

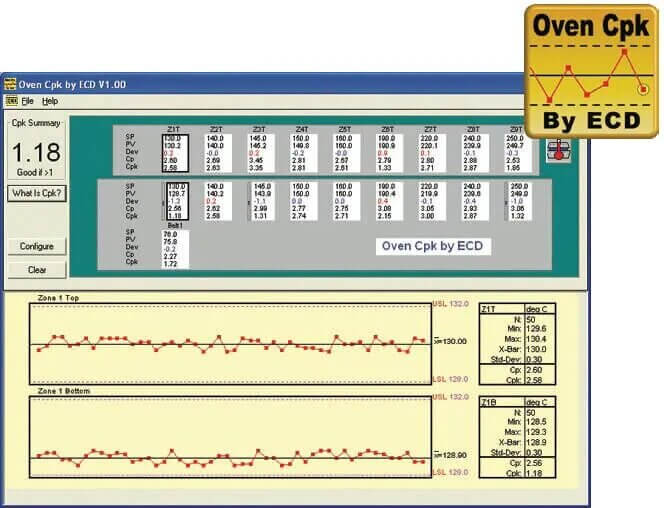

Process Control

Powered by ECD, this innovative software package provides three levels of process control from Oven CpK, to Process CpK and Product Traceability, this software ensures that all parameters are optimized and SPC reporting is fast and easy.

New Frame

More than simply beautiful, this new frame utilizes twice the insulation. This modification alone, reduces heat loss and saves up to 40% on electricity costs!

Lead Free Reflow Oven

More Lead free product has been run on our reflow machines than any other type of reflow machine! We have pioneered the Lead Free Reflow Machine process by working closely with the Japanese OEM’s and International ODM’s and EMS’s to refine the Lead Free process. The Mark III system includes features that provide:

- Spike Zone” design to minimize liquidous time

- Ultra fast cooling rates of 3-5 Deg/Sec to form perfect grain structure

- More heated zones than any other competitor to allow “Profile Sculpting

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky