ERSA EXOS 10/26 Reflow Soldering Oven

Ersa answers the demands of electronics manufacturing for pore-free solder joints - especially for power electronics and high-reliability technology - with the EXOS 10/26, a convection reflow soldering system with 22 heating chambers and 4 cooling zones as well as a vacuum chamber after the peak zone, which can reduce the void rate by an impressive 99%. Thanks to intelligent features, the EXOS 10/26 can produce particularly economically and "void-free".

Technology Highlights Reflow Soldering System EXOS 10/26

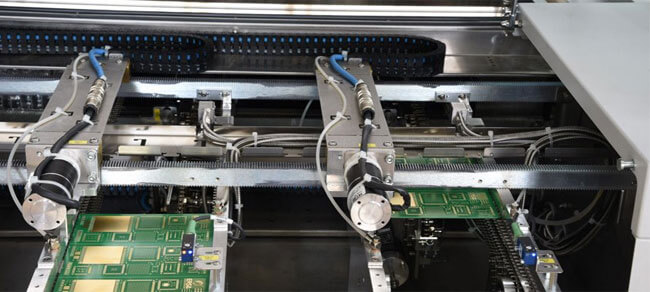

4-part conveyor (infeed, preheating and peak, vacuum, cooling zone) also as dual track

Perfect synchronization of the assemblies and transitions thanks to sensor-monitored conveyor, no external infeed module required

Maintenance-friendly and lubricant-free roller conveyor in the vacuum module

Optimum access to the vacuum chamber through lifting unit from above

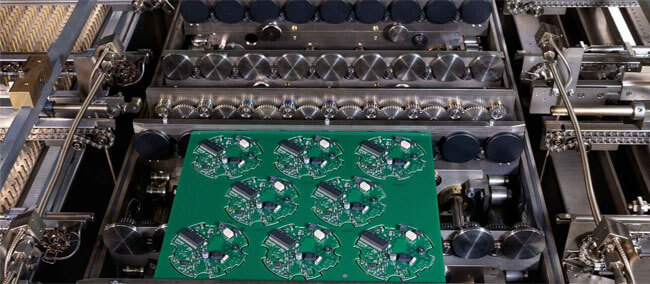

Optimum temperature profiles through medium-wave emitters in the vacuum module

Maximum machine availability thanks to fast removal of the conveyor unit in the vacuum module

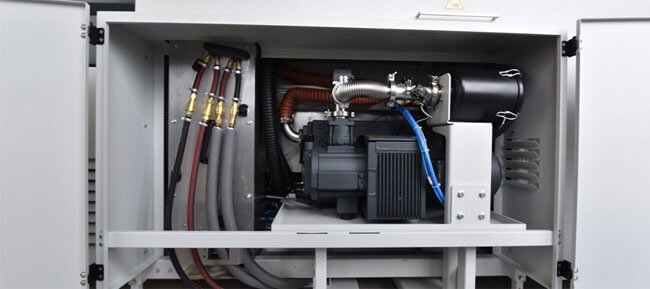

Part-integrated vacuum pump on separate module carrier for easy and fast maintenance

Innovative cleaning system SMART ELEMENTS®

EXOS 10/26: Safe processes, maximum throughput - minimum footprint thanks to innovative transport system

EXOS 10/26: Roller transport - highest assembly quality and machine availability

EXOS 10/26: Medium-wave emitters - optimum temperature profiles with vacuum process

EXOS 10/26: Vacuum module - maximum safety and ease of maintenance

Technical data Ersa Reflow Soldering System EXOS 10/26

| Dimensions | |

| Length | 7,875 mm |

| Height | 1,969 mm |

| Width | 2,195 mm |

| Weight with options | 5,000 kg |

| Conveyor system | |

| Working width | 50-630 mm |

| Transport speed | 20-200 cm/min |

| Working width (centre support) | 100-630 mm |

| Transport over ground | 820-980 mm |

| Throughput height | +/-35 mm |

| Pin chain transpor | 5 mm overlay |

| Centre support, strap height | 11 mm |

| Heating system | |

| Convection rate (except vacuum chamber) | 100% |

| Soldering zone | 2 top/2 bottom |

| Volumetric flow/module | 500 m3/h adjustable, Multijet |

| Nominal power/modul | 3,3/4,5/9,0 kW |

| Convection heating modules | 11 top/11 bottom |

| Heating system vacuum chamber | 2x regulated (4,8/6,8 kW) |

| Preheating | 9 top/9 bottom |

| 3 medium wave heaters | 1x set (4 kW) |

| Vacuum chamber | |

| Chamber volum | approx. 110 l |

| Ultimate pressure | up to 10 mbar |

| Pump capacity | up to 240 m3/h or 5,3 kW |

| Electrical data | |

| Voltage | 5-wire network, 3x 400 V, N, PE |

| Nominal power | 118-150 W |

| Voltage tolerance | +/-10% |

| Power reduced | 55 kW |

| Frequency | 50/60 Hz |

| Continuous power in operation | approx. 14-25 kW |

| max. back-up fuxe | 3x 100 A |

| Exhaust | |

| Exhaust nozzle | 2 pieces, each 150 mm (diameter) |

| Exhaust air monitoring per nozzle | |

| Extraction capacity per nozzle | 400 m3/h |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky