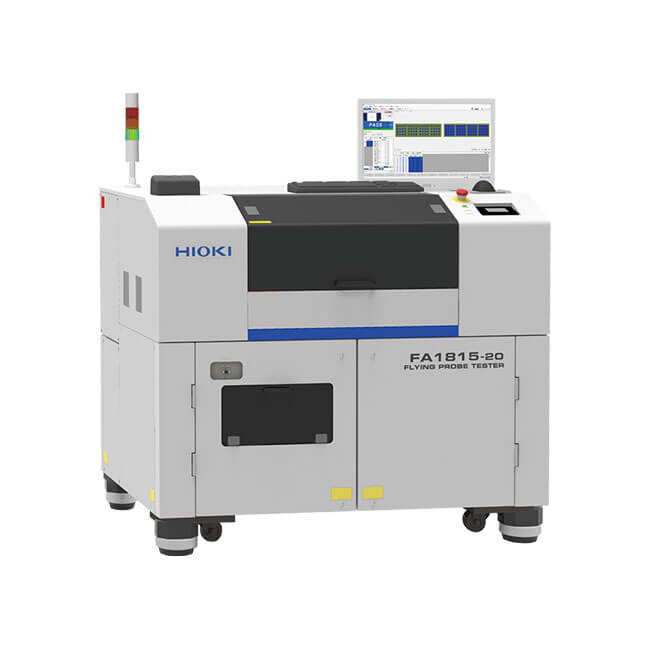

HIOKI FA1815-20 Flying Probe Tester

With remarkable progress in IT technology driving the semiconductor industry forward, reliability and productivity have become indispensable. Flying probe testers have long been the industry standard tool for PCB inspection. However, as inspection demands grow more stringent, the FA1815-20 emerges as the next-generation flying probe tester, ready to meet the challenges of precision and speed head-on. Moreover, this tester introduces an innovative approach to insulation resistance inspection that minimizes some cautious users’ concern about board damage with high-voltage testing in high-resistance inspections. This advancement represents Hioki's commitment to providing market-leading solutions that contribute to societal progress.

Unmatched probing precision: The FA1815-20 achieves a probing resolution with a minimum pitch of 34 µm between patterns and can inspect circuit test pads as small as 4 × 4 µm square. This precision is essential for today's increasingly fine circuit patterns.

Key Features

Improved takt time due to market-leading technology

High reliability due to high probing precision

Insulation testing up to 100 GΩ is enabled with an applied 10 V

Specifications Overview

Number of arms

4 (2 each, top and bottom)

Compatible probes

1172 series, CP1072 series, CP1073 series

Number of test steps

Max. 4,000,000 steps

Test parameters and measurement ranges

DC constant-current continuity measurement

400.0 mΩ to 1.000 kΩ

DC constant-current resistance measurement

40.00 μΩ to 400.0 kΩ

DC constant-voltage resistance measurement

4.000 Ω to 40.00 MΩ

Insulation resistance measurement

1.000 kΩ to 100.0 GΩ

Low voltage insulation resistance measurement

1.000 MΩ to 100.0 GΩ

AC constant-voltage capacitance measurement

100.0 fF to 10.00 μF

Leakage current measurement

1.000 μA to 100.0 mA

High-voltage resistance measurement

1.000 kΩ to 100.0 GΩ

Capacitor insulation measurement

1.000 kΩ to 250.0 MΩ

Open measurement

4.000 Ω to 4.000 MΩ

Short measurement

400.0 mΩ to 40.00 kΩ

Test parameters and measurement for component-embedded board tests

LSI connection test

0.000 V to 12.00 V

AC constant-voltage resistance measurement

10.00 Ω to 10.00 kΩ

AC constant-voltage capacitance measurement

10.00 pF to 100.0 μF

AC constant-voltage inductance measurement

1.000 μH to 1.000 mH

Judgment range

-99.9% to +999.9% or absolute value

Movement resolution

XY: 0.1 μm/pulse; Z: 1 μm/pulse

Minimum pad pitch

Top surface: 34 μm (with CP1075-09)

Bottom surface: 44 μm (with CP1075-09)

Minimum pad size

Top surface: 4 μm square (with CP1075-09)

Bottom surface: 14 μm square (with CP1075-09)

Measurement speed

Max. 100 points/sec. (0.15 mm movements, 4-arm simultaneous probing, capacitance measurement)

Testable board size

Thickness : 1 mm (0.04 in.) to 12 mm (0.47 in.)

Outer dimensions : 50 mm (1.97 in.) W × 50 mm (1.97 in.) D to 340 mm (13.39 in.) W × 340 mm (13.39 in.) D

Maximum testable area

340 mm (13.39 in.) W × 340 mm (13.39 in.) D

Clamp method

Flexible Fixture

Vacuum Unit for Capacitance Test (Options)

Air requirements

Primary-side pressure: 0.5 MPa to 0.99 MPa (dry air)

Maximum consumption: 0.3 L/min. (ANR)

Power supply

200 V, 220 V, 230 V, 240 V AC single-phase (specified at time of order);

50/60 Hz; maximum power consumption: 5 kVA

Dimensions and weight

1355 mm (53.35 in.) W × 1190 mm (46.85 in.) H × 1265mm (49.8 in.) D(excluding protruding parts);

1100 kg ±50 kg (38800 oz. ±1763 oz.)

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky