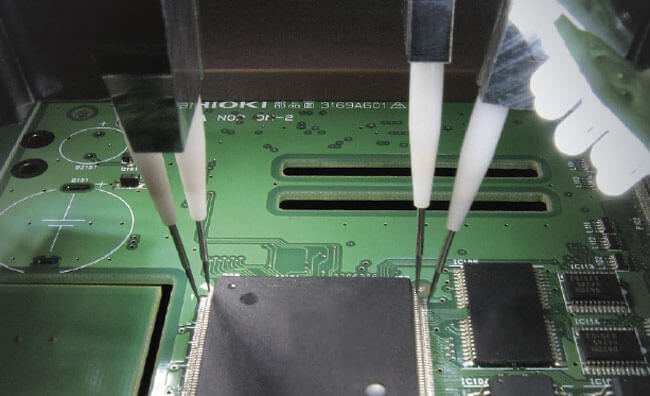

HIOKI FA1240-6x Flying Probe Tester

Hioki PCB and substrate inspection equipment leverages our core competency in high precision component testing. The FA1240 series is a 4-arm populated board inspection tool that delivers multi-functional testing in as fast as 0.025 sec./step.

High accuracy and automated welding quality assurance solution for battery module

Completely independent 4-Arm movement.

Very easy to change probing point.

Never mind even though different terminal layout mixing.

Test two cells in parallel

Key Features

Quickly complete programs that take into account component height

Automatically calculate arm interference (when used with the UA1780)

Designed to improve probe replaceability, dramatically reducing system downtime caused by probe replacement

High-speed testing at up to 0.025 sec./step

Proprietary Hioki lead float detection reliably detects issues up to and including pseudo-contact

Provides a superior level of solder quality assurance

Phase-isolated measurement and guarding functionality are ideal for analog circuits

Support for active testing (optional feature)

Large testing area of 510 × 460 mm (FA1240-61)

Automatic alignment function and simple visual test function

Features

Electrical Testing Verifies Correct Mounting

Create a program from the design data, perform electrical testing with minimal time and cost, and quickly confirm and record defects.

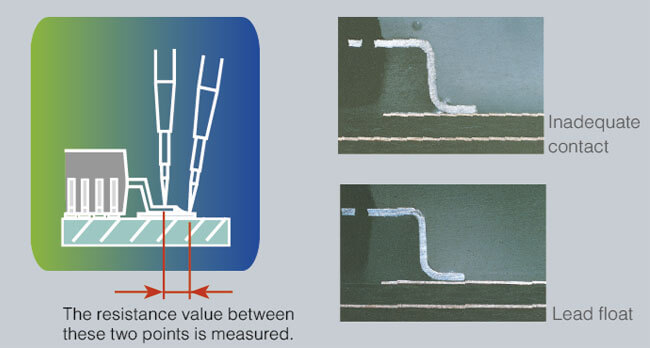

Lead float and pseudo-contact are not the same thing.

Pseudo-contact of leads is a type of defect that may slip through various tests during the board manufacturing process and make its way into the market.

Lead float can be fairly reliably identified by today's image inspection technology.Consequently, Hioki's proprietary resistance measurement pseudo-contact test serves to detect pseudo-contact, which is difficult to identify based on appearance alone.

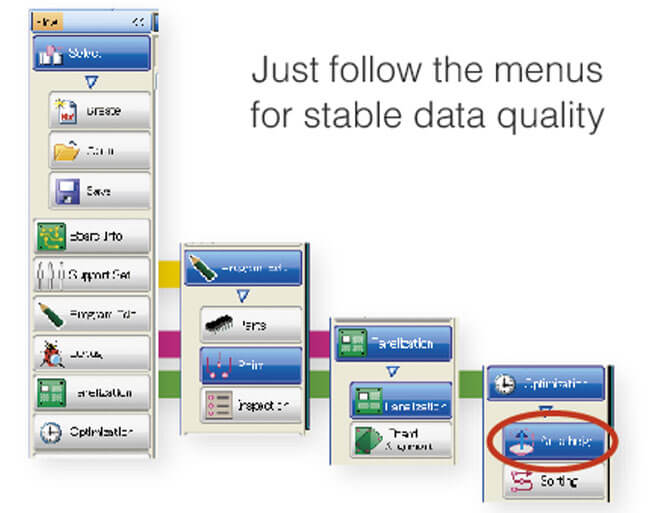

Focusing on the supreme importance of test points and Gerber data

It's half true, and half untrue, to say that the ability to easily create data is distinct from the ability to easily test boards.Being able to create data easily may have meant being able to test boards easily during the discrete era, but in creating the test data required by the FA1240, it is critical that creating accurate test data be a simple and easy-to-perform process.

By minimizing the difference between data that's good enough to operate the tester and data that's good enough to ship products, it is possible to minimize production line downtime (to allow for debugging and other modifications) and to ship products with peace of mind.

Simply follow the workflow.

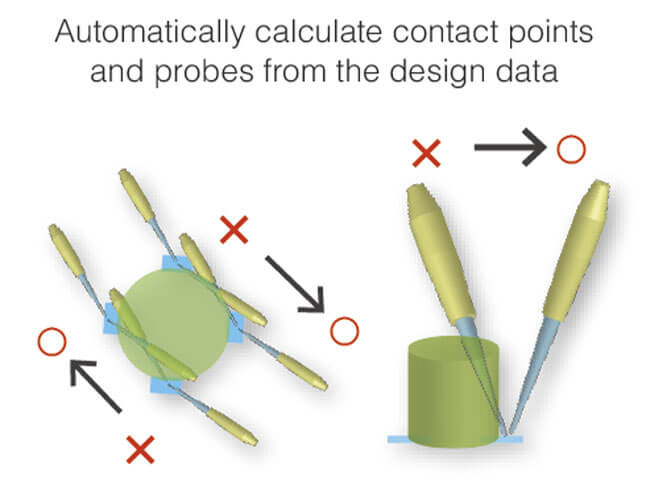

Quickly complete programs that take into account component height

Automatic calculation of arm interference (when used with the UA1780)

Do you check data by looking at probe tips and asking yourself whether they'll strike components on the board or not?

In fact, choosing probes used to be a demanding and time-consuming part of the debugging process that required a high degree of care.By adding component height information to mounting data, the FA1240 is able to automatically select an appropriate test probe, allowing you to approach the task of debugging electrical testing with peace of mind.

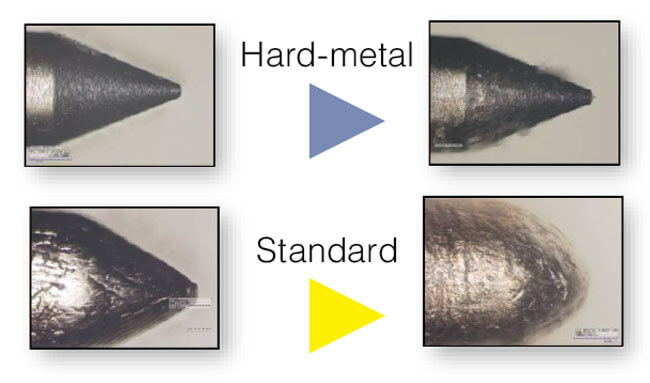

Long-life probes (easy replacement NEW and long service life)

The tips of Hioki's new super-hard probes show no wear, even after 3 million contact cycles.

Stable contact for up to 3,000,000 uses, prevents pseudo-contact due to slips

Specifications Overview

|

|

FA1240-63 |

|

|

|

FA1240-61 |

|

||

|

FA1241-61 |

|

||

|

Number of arms |

4 (L, ML, MR, R) |

||

|

Number of test steps |

40,000 (max.) |

||

|

Measurement ranges |

Resistance: 400 μΩ to 40 MΩ |

||

|

Capacitance: 1 pF to 400 mF |

|||

|

Inductance: 1 μH to 100 H |

|||

|

Diode VZ measurement: 0 to 25 V |

|||

|

Zener diode VZ measurement: 0 to 25 V, 25 to 80 V (optional feature) |

|||

|

Digital transistors: 0 to 25 V |

|||

|

Photo couplers: 0 to 25 V |

|||

|

Short: 0.4 Ω to 400 kΩ |

|||

|

Open: 4 Ω to 40 MΩ |

|||

|

DC voltage measurement: 0 to 25 V |

|||

|

Measurement time |

Max. 0.025 sec./step |

Max. 0.025 sec./step |

|

|

Probing precision |

Within ±100 μm for each arm (X and Y directions) |

||

|

Positioning repeatability |

Within ±50 μm (probing positions) |

||

|

Inter-probe pitch |

Min. 0.15 mm |

Min. 0.15 mm |

|

|

Min. 0.5 mm (when using 4-terminal probes) |

Min. 0.5 mm (when using 4-terminal probes) |

||

|

Testable board dimensions |

510 mm (20.08 in) W × 460 mm (18.11 in) D |

400 mm (15.75 in) W × 330 mm (12.99 in) D |

|

|

Power supply |

200 V AC (single-phase), 50/60 Hz, 6 kVA (FA1241: 230 V AC) |

200 V AC (single-phase), 50/60 Hz, |

|

|

5 kVA |

|||

|

Dimensions and mass |

1406 mm (55.35 in) H × 1300 mm (51.18 in) H × 1380 mm (54.33 in) D, 1150 kg (40,564.4 oz) |

1266 mm (49.84 in) H × 1369 mm (53.90 in) H × 1425 mm (56.10 in) D, 1050 kg (37,037 oz) |

|

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky