HIOKI FA1283 Flying Probe Tester

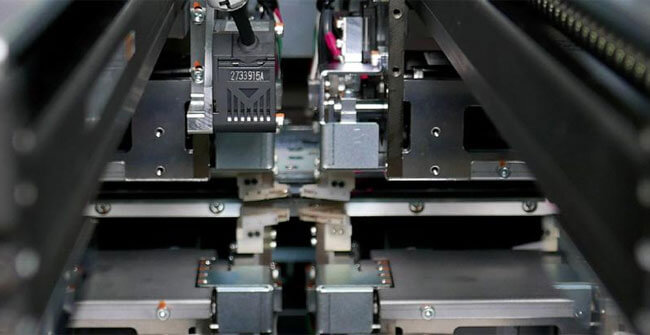

Hioki PCB and substrate inspection equipment leverages our core competency in high precision component testing. The FA1283 is a horizontal-loading, double-sided flying probe tester with rapid 100 times/second test speed.

Key Features

Max. 100 points/s ultra-high speed inspection

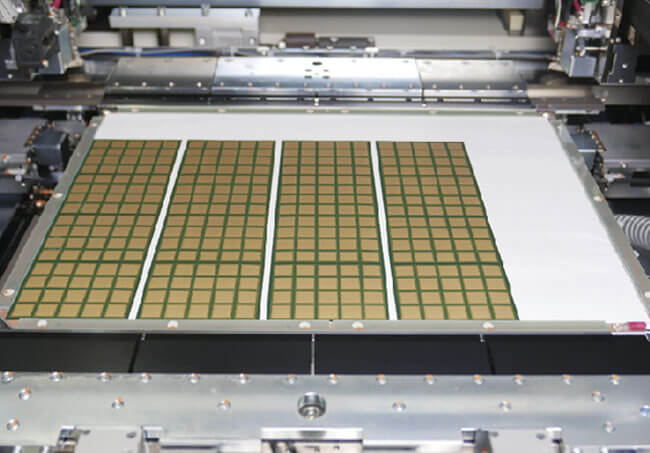

Inspect general bareboards to fine and high density substrates such as flexible substrate and CSP

Full lineup of functions including capacitance measurement and testing of diodes and other embedded components

Complete Electrical Testing of High-Function Boards with a Single Unit

The FA1283 is a next-generation bare board testing system that incorporates component measurement expertise accumulated by Hioki in the course of developing populated board testing products.

Down to the 1μm

A High-Accuracy FLYING PROBE TESTER Aiming at φ10 μm Contact

Total Probing Accuracy □ 15 μm (when FA1971-01 is installed)

Not One Second Wasted

A smooth start to initial testing is vital.

Electrical testing schedules are short and strict.

・Tension Clamp Equipped as Standard

・Laser board thickness correction unit that measures board flex and undulation

・Capacitance measurement vacuum stage for testing boards that cannot be clamped (optional)

・Available in both offline and automatic transport variants.

・FEB-LINE Data Creation System UA1781 provides accurate data, even for complex designs.

Total Measurement Mastery

A single unit for everything from simple continuity and insulation testing to advanced function measurements for component testing.

A testing unit and measurement unit for selection and analysis.

This high-potential flying probe tester is designed to fit your needs.

Vacuum Unit for Capacitance Test E4001

Nothing ships without electrical testing.

Vacuum absorption stage E4001 is used to perform capacitance method O/S testing, which is unaffected by board shape.

Perform stable testing independent of board dimensions or thickness.

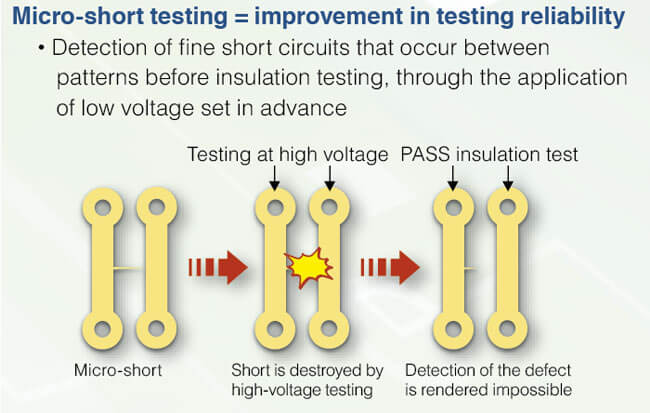

Improving the quality of insulation testing

The tester's insulation test capabilities have a direct impact on product quality when it comes to phenomena such as burning up micro-shorts and arcing during testing.

The FA1283 can perform super-high-speed insulation testing at 100 GΩ/10 msec.

It also provides a variety of functions designed to guarantee a high level of insulation quality, including micro-short detection, arc detection, bipolar testing, and impulse testing.

Mastering continuity testing and resistance measurement

Users can select from multiple modes, including 4-terminal low-resistance measurement, 200 mA continuity measurement, and capacitance measurement O/S testing.

Use 4-terminal measurement to detect increases in wiring resistance caused by phenomena such as open vias, and use continuity testing at large currents of up to 200 mA to guarantee board integrity under conditions that approach actual operation.

The FA1283 provides numerous measurement modes that are made possible by Hioki's unique measurement expertise, from low-voltage resistance measurement at 0.1 V to high-voltage resistance measurement for materials such as ITO that have high insulation resistivity.

Embedded Device Measurement: A Sharp Departure from LCR Measurement

The FA1283 is a next-generation bare board testing system that incorporates component measurement expertise accumulated by Hioki in the course of developing populated board testing products.

Its measurement capabilities range from basic measurement functions such as MLCC measurement to guard functionality for measuring composite circuits, phase separation measurement, and other capabilities that go beyond the typical features of in-circuit testers,It also delivers dedicated modes such as current consumption testing and leakage current testing for use in LSI reliability testing.

These functions are ideal for testing populated boards and differ from those offered by LCR meters.

Half of Data Generation Time With New Platform FEB-LINE UA1781

Flying probe test for Embedded and Bare boards UA1781

3-in-1 Editing Software for Bare Boards Testing

Edit data and Generate test point and Built-in component support

・3-in-1 for editing, test-point generation, and built-in component support

・New Windows-optimized algorithm

・Free from data volume restrictions for increased freedom

・Added new commands to reduce data generation time by half

Specifications Overview

|

Number of arms |

4 (2 each, top and bottom) |

|

|

Mountable probes |

1172 series |

|

|

Number of test steps |

Max. 900,000 steps |

|

|

Measurement parameters and measurement ranges |

Resistance : |

40.00 μΩ to 100.0 MΩ |

|

Capacitance : |

10.00 fF to 40.00 mF |

|

|

Inductance : |

10.00 μH to 100.0 mH |

|

|

Diode VZ measurement : |

0.000 V to 25.00 V |

|

|

Insulation resistance : |

200.0 Ω to 100.0 GΩ |

|

|

Capacitance Insulation resistance : |

200.0 Ω to 10.00 MΩ |

|

|

High voltage resistance : |

200.0 Ω to 25.00 GΩ |

|

|

High voltage short resistance : |

400.0 mΩ to 400.0 kΩ |

|

|

Leak current measurement : |

100.0 nA to 10.00 mA |

|

|

Zener diode VZ measurement : |

0.000 V to 25.00 V |

|

|

Digital transistor measurement : |

0.000 V to 25.00 V |

|

|

Photo couplers measurement : |

0.000 V to 25.00 V |

|

|

Continuity test : |

400 mΩ to 1.000 kΩ |

|

|

Open test : |

4.000 Ω to 4.000 MΩ |

|

|

Short test : |

400.0 mΩ to 40.00 kΩ |

|

|

DC voltage measurement : |

40.00 mV to 25.00 V |

|

|

Judgment range |

-99.9% to +999.9% or absolute value |

|

|

Minimum pad pitch |

35um (with CP1075-09)(when using FA1971-01) |

|

|

40um (with CP1075-09) |

||

|

Minimum pad size |

5um (with CP1075-09)(when using FA1971-01) |

|

|

10um (with CP1075-09) |

||

|

Measurement speed |

Max. 100 points/ s (X-Y movements of 0.1 mm, 4-arm simultaneous probing, when capacitance measurement) |

|

|

Testable board size |

Thickness : 0.1 mm to 2.5 mm (0.10 in) |

|

|

Outer dimensions : 50 mm (1.97 in) W × 50 mm (1.97 in) D to 400 mm (15.75 in) W × 330 mm (12.99 in) D |

||

|

Maximum testable area |

400 mm (15.75 in) W × 324 mm (12.76 in) D |

|

|

Board clamping |

Board 2-side chuck method (with tension function) |

|

|

Power supply |

200 V, 220 V, 230 V, 240 V AC single-phase (specify at time of order), 50/60 Hz, 5 kVA |

|

|

Dimensions and mass |

1360 mm (53.54 in) W × 1200 mm (47.24 in) H × 1280 mm (50.39 in) D, (Excluding protruding parts), 1,100 kg (38,800.7 oz) |

|

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky