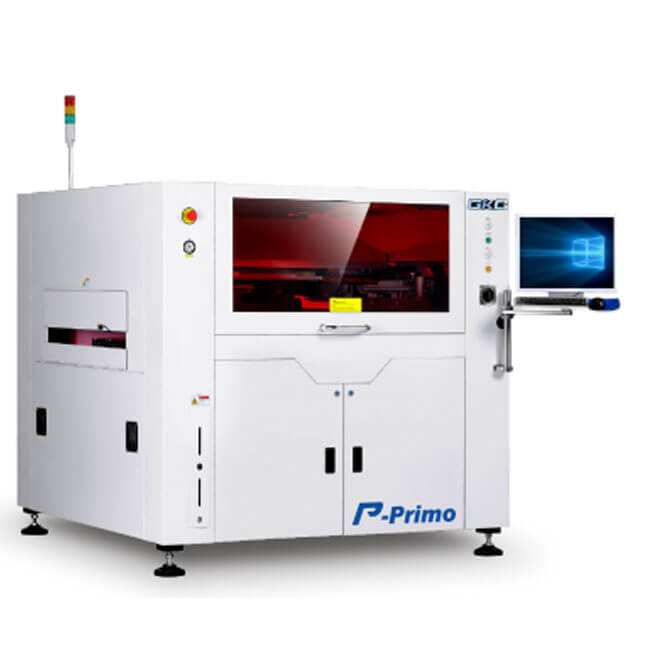

GKG P-Primo Solder paste printer

The Large Platform SMT Screen Printer

Catering to customers’ ultra large printing needs, P-Primo is the ideal printer that serves XL size PCB of up to 850mm x 610mm. The 2D paste inspection function is able to detect insufficient paste, bridging and other defects. Like all our other GKG machines, P-Primo undergoes numerous stringent tests to certify its capability.

|

Performance |

|

|

Machine Alignment Capability |

2Cmk @ ±12.5 microns 4 Sigma |

|

Process Alignment Capability |

2Cpk @ ±25 microns 4 Sigma |

|

Core Cycle Time |

< 12 secs |

|

(excluding printing & cleaning time) |

|

|

Product Changeover Time |

< 5 mins |

|

New Product Set-up Time |

< 10 mins |

|

Board Handling |

|

|

Max. Size (L x W) |

850 mm x 610 mm |

|

Min. Size (L x W) |

100 mm x 65 mm |

|

Thickness |

0.4~8 mm |

|

PCB Thickness Adjustment |

Automatic |

|

PCB Max. Weight |

10 kg |

|

PCB Edge Clearance |

3.5 mm |

|

PCB Bottom Clearance |

23 mm |

|

PCB Warpage |

Max. 1% diagonally |

|

Clamping Method |

Retractable top clamp, motor controlled side clamp |

|

Support Method |

Magnetic support pins, bars, blocks, vacuum suction |

|

Conveyor Direction |

L to R, R to L, R to R, L to L (software control) |

|

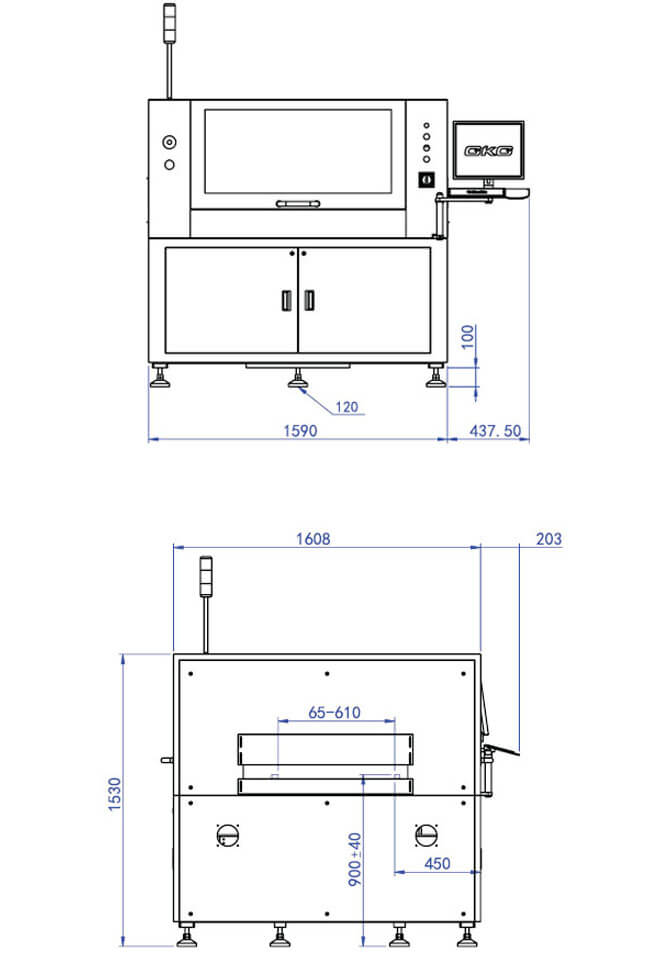

Conveyor Height |

900 ± 40 mm |

|

Conveyor Speed |

Max. 1,500 mm/s |

|

Conveyor Width Adjustment |

Automatic |

|

OPERATOR INTERFACE |

|

|

Hardware |

LCD Monitor, Mouse & Keyboard |

|

Operating System (OS) |

Windows 10 |

|

Control Method |

Industrial PC controlled |

|

I/O Interface |

SMEMA Standard |

|

OPTICAL SYSTEM |

|

|

Field-of-View (FOV) |

8 mm x 6 mm |

|

Fiducial Types |

Circle, triangle, square, diamond, cross |

|

Fiducial size |

0.5~4.0 mm |

|

Vision Methodology |

CCD camera look up & down |

|

2D inspection |

Max. 100 windows to inspect missing, |

|

insufficient, bridging (std.) |

|

|

PRINTING PARAMETERS |

|

|

Stencil Frame Size (L X W) |

Adjustable, 737 mm x 737 mm to |

|

1,100 mm x 950 mm |

|

|

Print Gap (snap-off) |

0~20 mm |

|

Printing Table Adjustment Range |

X: ±10 mm, Y: ±10 mm/ : ± 2° |

|

Print Speed |

5~150 mm/s |

|

Squeegee Pressure |

0.5~20kg (program control) |

|

Squeegee Type |

Std.: Metal, Option: Rubber |

|

Squeegee Angle |

Std. 60°, Option 45°, 50°, 55° |

|

Cleaning System |

Auto wet, dry, vacuum (Software select) |

|

FACILITIES REQUIREMENT |

|

|

Power Supply |

AC220V ± 10% 50/60Hz |

|

Power Consumption |

3kW |

|

Air Supply |

4 ~ 6Kgf/cm² |

|

Dimension (excluding signal tower) |

1,590 mm (L) x 1,608mm (W) x 1,530 mm (H) |

|

Machine Weight |

1,500 kg |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky