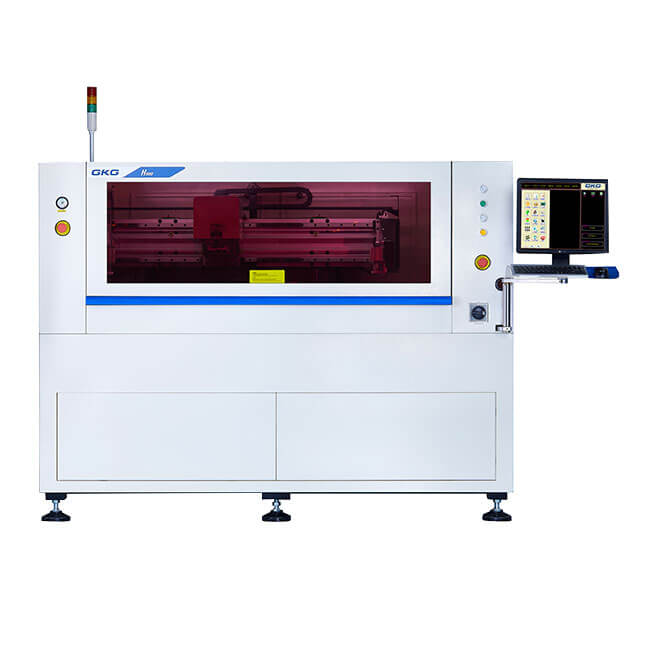

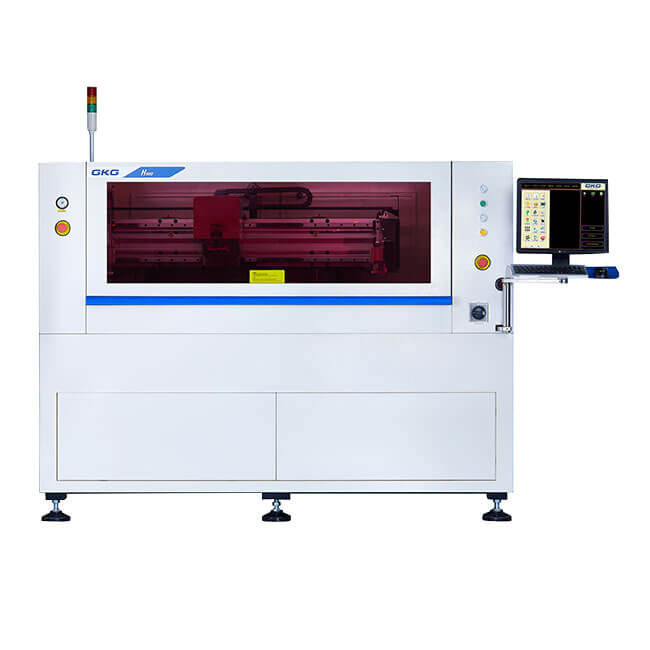

GKG H900 Solder paste printer

Product characteristics

1. High-precision LED chip lamp with special equipment, with special solidification equipment, can provide special whole line equipment and process plan;

2. Programmable suspension horizontal (X-direction) adaptive printing structure to ensure pressure stability;

3. Equipped with 1.3 million pixel digital camera, 10*8mm FOV field of view, perfectly compatible with all types/coating MARK;

4.GKG standard MES system can collect equipment parameters, debugging information, material monitoring and information capture, and realize the ability to control the output link in real time and comprehensively trace the production data.

Specifications

|

Machine Performance |

|

|

Repeat Position Accuracy |

±0.015mm |

|

Print Accuracy |

±0.03mm |

|

Based on the third party test system(CTQ)Verify the actua| solder paste printing position repeat precision |

|

|

Cycle time |

<15sec |

|

Machine parameter |

|

|

Power Source |

AC:220 ±10%,50/60Hz 3KW |

|

Air Pressure |

4~6Kgf/cm² |

|

Air Consumption |

About 5L/min |

|

Operating Temperature |

-20℃~+45℃ |

|

Working environment humidity |

30%~60% |

|

Machine dimension(without Tower light) |

1509(H) mm |

|

Machine Length |

1970(L) mm |

|

Machine Width |

1210(W) mm |

|

Machine Weight Approx |

Approx: 1500Kg |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky