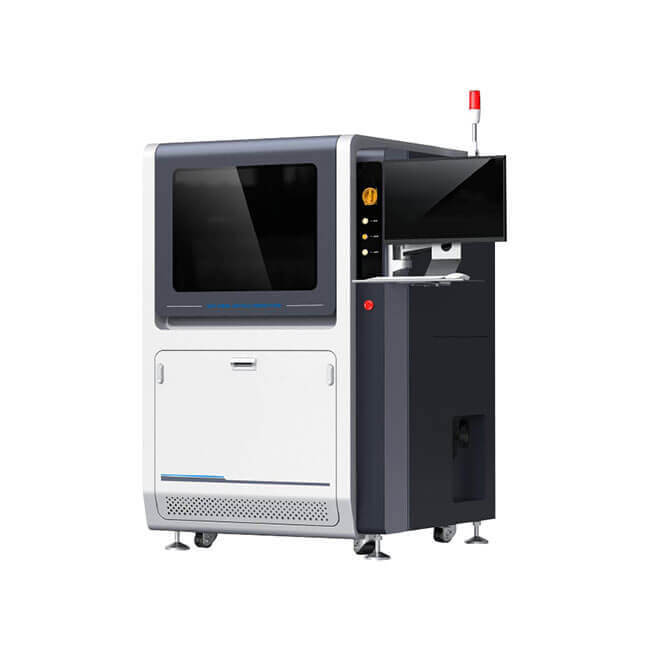

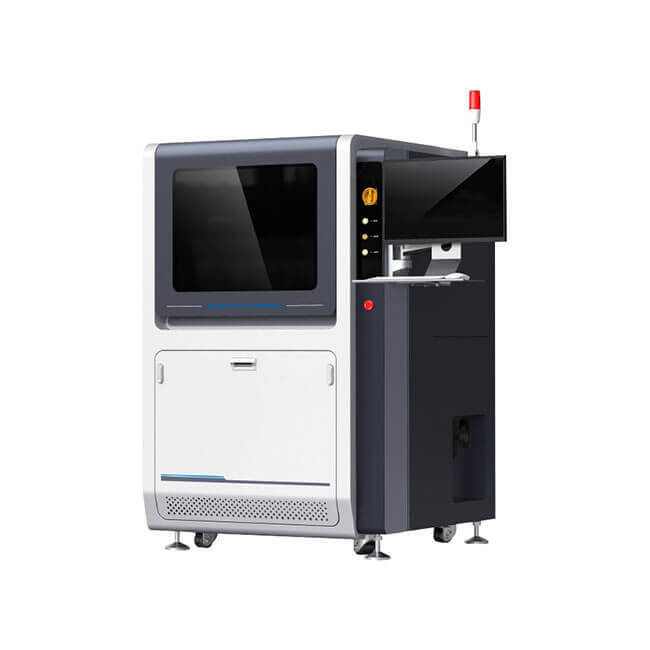

FAI1095 Automatic First Article Inspection Machine

Enhanced Efficiency: Achieve a fivefold increase in efficiency through automated material clamping and component detection.

Precise and Reliable: Advanced AI systems ensure accurate error identification, minimizing human errors and omissions.

Streamlined Documentation: Traceable and tamper-proof test records, along with automated report generation, simplify documentation.

Versatile Compatibility: Compatible with various BOM formats for seamless integration into diverse manufacturing setups.

Overview

FAI1095 First Article Inspection Machine

The First Article Inspection Machine, known as the FAI1095, represents a paradigm shift in PCBA testing, transcending the limitations of traditional manual methods. This advanced device integrates a First Article Inspection Machine detection method with sophisticated software, enabling fully automated material clamping and component detection.

Its efficiency, five times greater than conventional FAI detectors, minimizes production line changeover times, optimizing production line utilization. With automated LCR detection and an advanced AI system, it ensures precise identification of errors and real-time data display, enhancing accuracy and preventing human errors.

Moreover, its fully automatic test judgment streamlines the testing process, eliminating manual interventions and improving overall efficiency. Additionally, the machine’s high-definition graphics and optical comparison capabilities facilitate meticulous examination, while its traceable test records and automated report generation ensure comprehensive documentation and traceability throughout the testing process.

Key Features

Labor Replacement with Automated Detection: By automating LCR detection processes, the First Article Inspection Machine eliminates manual intervention, substantially saving labor and enhancing speed by at least 3-5 times, achieving an average detection speed of 1 second per component. Its superiority becomes more pronounced with increasing component density on the board.

Advanced Artificial Intelligence System: Leveraging an advanced AI system, the machine adeptly identifies erroneous or repeated BOM consumption, multiple and small pieces, reversals, and incorrect materials. Real-time synchronous display of detection data effectively prevents human errors and omissions, ensuring robust accuracy.

Fully Automatic Test Judgment: The testing process is entirely automated, obviating the need for manual material insertion, range switching, or manual comparison of measured values. The system autonomously discerns between PASS and FAIL criteria, streamlining the testing procedure.

High-Definition Graphics and Optical Comparison: Offering PCBA high-definition graphics with magnification capabilities, the system facilitates meticulous examination of real objects. It performs optical comparison detection seamlessly without manual intervention, ensuring precision and accuracy.

Traceable Test Records and Report Generation: With real-time, unmodifiable test record keeping, and the ability to restore detection scenes, traceability is ensured. Additionally, the machine automatically generates comprehensive test reports, available in Excel and PDF formats, complete with component images and pertinent PCBA information.

Specification

|

Model |

FAI1095 |

|

Max PCB Size |

350mm*450mm |

|

PCB Height |

Up 25mm, Bottom 50mm |

|

Accuracy |

0.05% |

|

Measurement Display Range |

R: 0.01m ohms ~ 99.9999M ohms |

|

L: 0.01nH ~ 9999.9H |

|

|

C: 0.00001pF ~ 9.9999F |

|

|

Test Frequency |

20Hz ~ 300KHz |

|

Dimensions |

1085*1122*1638mm |

|

Weight |

700KG |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky