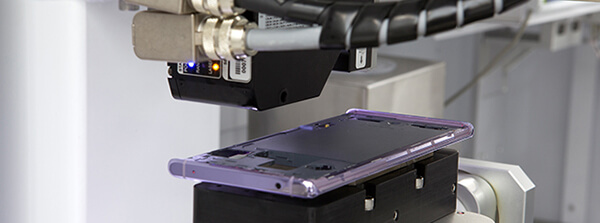

Axxon Mycronic AM300D five axis synchronized dispensing machine

Axxon Mycronic's AM300D is a five axis synchronized dispensing system with dual stations, designed for contoured applications such as smart phone mid-frame dispensing, wearable product dispensing and other non-linear dispense applications.

The dispense path is guided by a 3D linear laser, actively combining five axis for synchronized dispensing. This enables new product form factors, reducing material waste and reducing interface layers. Capable of dispensing on any curved product, the system can recognize product differences and curvatures and compensate accordingly.

Product Features

Advanced five axis control: with powerful motion control system supports various curved, round, ellipse, conical and spline shape product dispensing for sealing and reinforcement applications. Widely used in smart phone screen and mid-frame, smart watch, AR, VR glasses products.

- Suitable for dispensing in any curved mid-frame

- Suitable for dispensing in any smart wearable product

- Dispensing path guided by 2D vision or 3D linear laser (option)

- 3D linear glue path inspection position

- Split XY axis structure, dispensing station is separated from guiding station for higher accuracy

- Reserved position for In-line dispensing module, machine can be modified to inline auto-operation

POWERFUL 3D DISPENSE ABILITY

With kinematic calibration technology, CCD auto captures the contour of round or curved shaped products. Software calculates the center position and calibrates all moving axis offsets. The 3D movement path transition is seamless and smooth, and the motion system is intelligent and precise.

INTELLIGENT AND EASY OPERATION

The five axis equipment obtains positioning template in real time via mark points and the product edge features.If there are offsets or misalignments, the system can compensate and alarm automatically if outside tolerance. Effectively preventing operation mistakes.

MODULAR DESIGN, FLEXIBLE OPTIONAL FUNCTIONS

Easy to operate and maintain, our modular design further enables the system to be configured with varying functions: QR code scanning, MES, UV spot cure, low fluid level sensor, automatic weighing and cleaning functions, etc.

- Fully automatic image recognition

- Five axis synchronized control technology

- Non-contact laser height measuring technology, automatic detection of product height, automatic adjustment of dispensing height

- Large offering of optional functions to meet different dispensing needs

Specifications

| Specification | AM300D |

| Power supply | AC 220V,18A,50/60Hz,4kW |

| Air supply | 90psi(5.5bar) |

| Dimension | 1,200x1,550x1,700(WxDxH) |

| Weight | 1,000kg |

| Communication | SMEMA |

| Dispensing area | 200x100mm(WxD) |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky