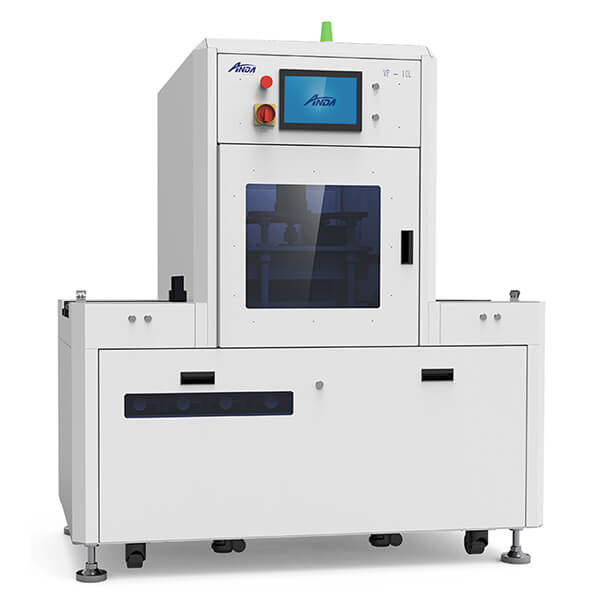

Anda VP10L Inline Vacuum Plasma cleaning machine

The VP-10L in-line vacuum plasma treatment machine is designed for continuous inline process operation. This series is designed for high vacuum plasma treatment operations, it ensures consistent quality and reduces vacuum plasma treatment time without the need to manually load/offload electrode batch trays. Vacuum plasma treatment is omnidirectional, during the process all surface areas of complex parts and materials are treated and activated simultaneously. Plasma cleaning is an important material surface modification that is actively used across many industries.

In the electronics industry, we highly recommend plasma treatment prior to selective conformal coating or dispensing processes in order to improve wetting of coatings and the adhesion strengths of coatings and other dispensed materials. When materials are plasma treated, coatings and adhesives are significantly less susceptible to fail. Plasma treatment to electronics ensures maximum protection from coatings and glues and a long product life for the intended device.

Features

- Inline Plasma Treatment: completely automated high production omnidirectional plasma treatment processing without need to manually load/unload batch electrode trays

- Multi-functional: system can be used as standalone or placed inline with upstream or downstream operation processes

- Ultra-low Temperature: system operation temperature as low as 40°C

- Omni-directional: complete immersion of the treated material by anisotropic plasma

- Environmentally Friendly: zero chemicals are used and no harmful substances are produced

- Cleaning: remove fine dust, oil, grease and organic compounds

- Activation: Increase surface energy to promote wetting and adhesion

VP-10L Specifications

|

Operation |

|

|

Chamber Size |

L 395 x W 390 x H 75 mm (L = 15.55” W = 15.35” H = 2.95”) |

|

Plasma Generator |

500 W |

|

Gas |

Oxygen + Nitrogen + Argon |

|

Vacuum Time |

≤ 15 s |

|

Vacuum Evacuation Time |

≤ 5 s |

|

Transmission System |

|

|

Process Flow |

L to R (Standard); R to L (Optional) |

|

Conveyor Type |

ESD belt |

|

Conveyor Height |

900 ± 20 mm (35.4” ± 0.78”) |

|

Convery Width Adjustment |

Automatic (Motorized) |

|

Driver |

Stepping motor |

|

Facility |

|

|

Standard footprint |

L 1600 x W 1010 x H 2000 mm (L 62.99” x W 39.76” x H 78.74”) |

|

Weight |

718 kg (326.36 lb) |

|

Air source |

0.4 - 0.6 Mpa |

|

Input power |

3 phase 380 V 4kW |

|

Interface |

|

|

Controller |

PLC with touch screen control |

|

Communication Protocols |

SMEMA & IPC-CFX |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky