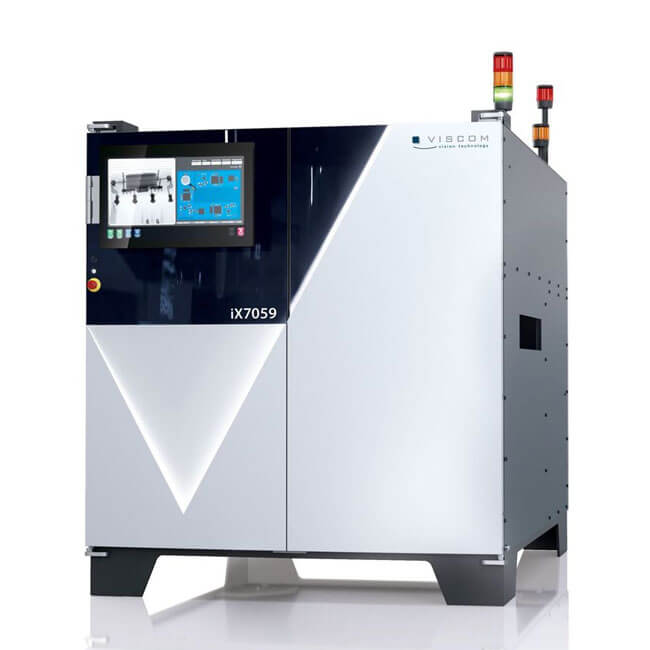

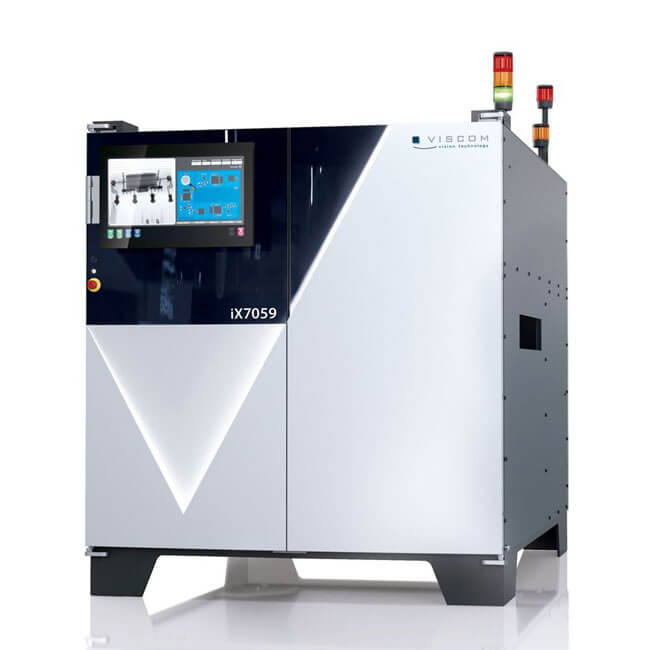

VISCOM iX7059 Module 3D X-ray Inspection Machine

iX7059 Module Inspection – High process efficiency through 3D X-ray and integrated CT

For manufacturers of power semiconductors, such as IGBT modules and SiC chips, compliance with safety and performance requirements is essential. The quality of each individual solder connection of the components ultimately determines whether overheating and thus failure will occur. The new iX7059 Module Inspection offers seamless and reliable quality assurance for this purpose. The fully automatic 3D X-ray system with integrated computed tomography is distinguished by easy-to-classify, accurate layer inspection images and a large inspection scope.

The X-ray system offers flawless handling of frame-based power modules or components on workpiece carriers. The iX7059 Module Inspection is compact and can be easily integrated into a line. There it fulfills - intelligently networked - all smart factory requirements.

ADVANTAGES AT A GLANCE

100% quality assurance

Future-proof, rapid 3D inline X-ray

Best defect coverage for zero defect strategy

Inspection of solid assemblies with 180kV

Intuitive programming

Inspection Scope

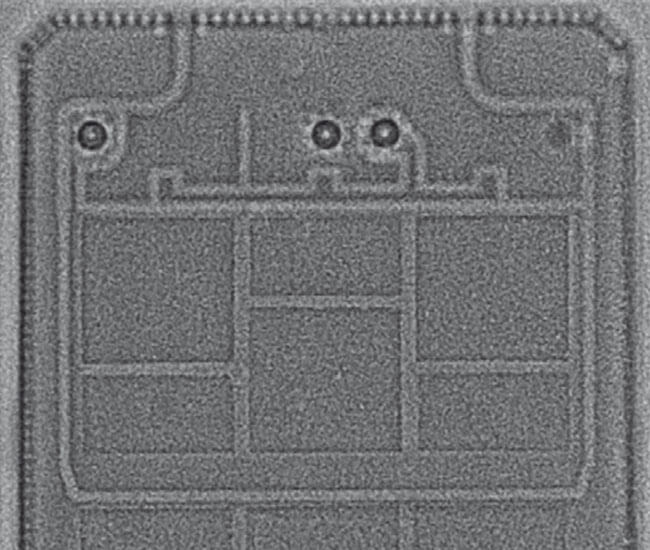

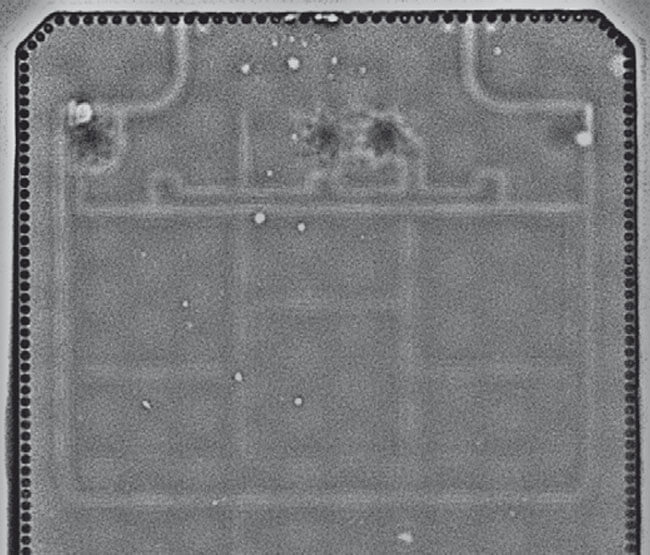

Solder inspection of chip layers

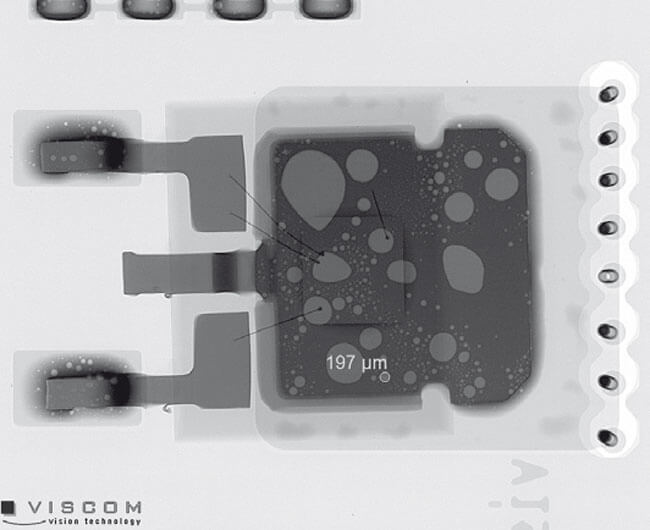

Solder inspection of DCB layers

DPAK with orthogonal radiography

HIGHLIGHTS

Precise solder joint inspection for IGBT modules and SIC chips

Intelligent checking of voids for flawless heat dissipation

Easy to classify, accurate layer test images

Fast handling of workpiece carriers and solder frames for maximum throughput

Fast inspection program creation thanks to 3D analysis and an IPC-compliant AXI inspection library

Maximum inspection program optimization through integrated verification

Additional vertical slices for optimum analyses and dependable verification

High-quality 3D AXI volume calculation with planar CT

CONNECTIVITY

Global libraries, global calibration: transferability to all systems

Automated grayscale value calibration for consistent inspection results

Traceability, statistical process control, offline programming, multiline verification

Viscom Quality Uplink: effective networking and process optimization

Interfaces: SMEMA, IPC Hermes Standard (optional)

INSPECTION

Scope of inspection: Twisted, missing or wrong component, hidden blow holes (voids) in surface soldering and THT solder joints

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky