UNICOMP LX9200 X-ray Inspection Machine

Unicomp Technology 3D Inline X-ray Inspection Equipment——LX9200

As a new generation of upgraded and optimized LX9200 online inspection equipment, it can easily meet the multi-directional and multi-angle product inspection needs of different users.

Application Field

Function Features

Off line programming , realtime program modification

In-line Automated X-Ray , inspection System

Repair Station , barcode reading+realtime display

Server , Database&SPC&MES

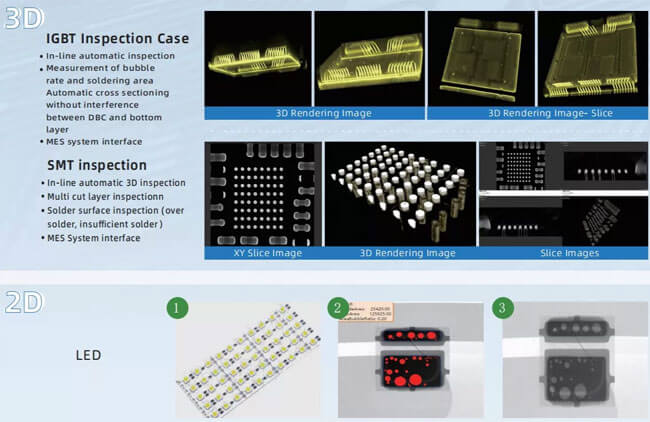

Inspection images

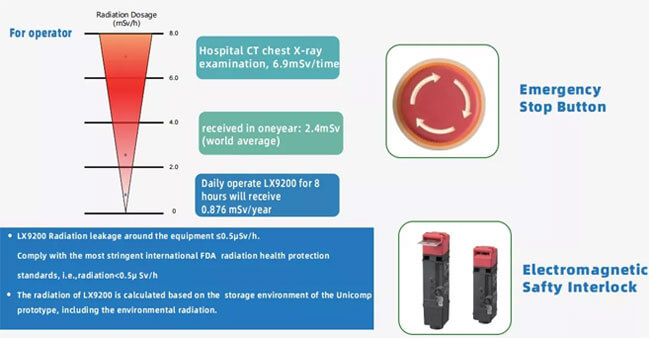

Safety Protection

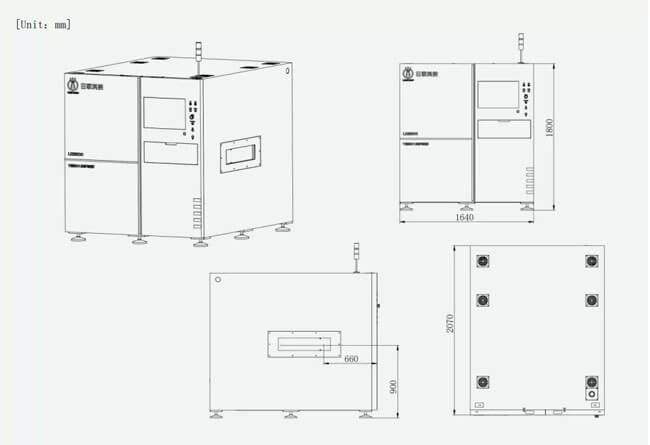

Dimensions and Appearance

Technical Parameters and Specifications

SMT Inspection Equipment Brand

Imaging system

Imaging method

2D, 2.5D, 3D (All in one)

X-ray source

Sealed tube (Max.130kv / 65w)

Detector

High resolution FPD (flat panel detector)

Image Resolution

9um,12um,18um,24um,30um (option 3um or 6um)

Camera

CCD camera

Main Body

Power supply voltage

110-220V

Power supply frequency

50/60HZ

Air pressure, capacity

0.4~0.6Mpa

Dimensions

1640mm(W) x 2070mm(D) x 1800mm(H)

Weight

3710Kg

Motion

High speed smooth flying capture(High precision linear motor + linear encoder

CT mode

Planar CT

PCBA

Conveyor height

900±50mm

Inspection Area

3D: 510mm X 670 mm ; 2D: 510mm X 730mm

Weight

max. 2kg (option:5kg)

Clearance

Top: 70mm ; Bottom : 40mm@30um

Application

Inspection object

BGA, CSP, SOP, QFP, QFN, POP, inserted components, chips, T/H, Press-fit CN, IGBT, etc.

Inspection Items

Missing, misalignment, void, open, non-wet, shifting, foreign object, bridging, tombstone, insufficient / excess solder, solder ball, wrong polarity etc.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky