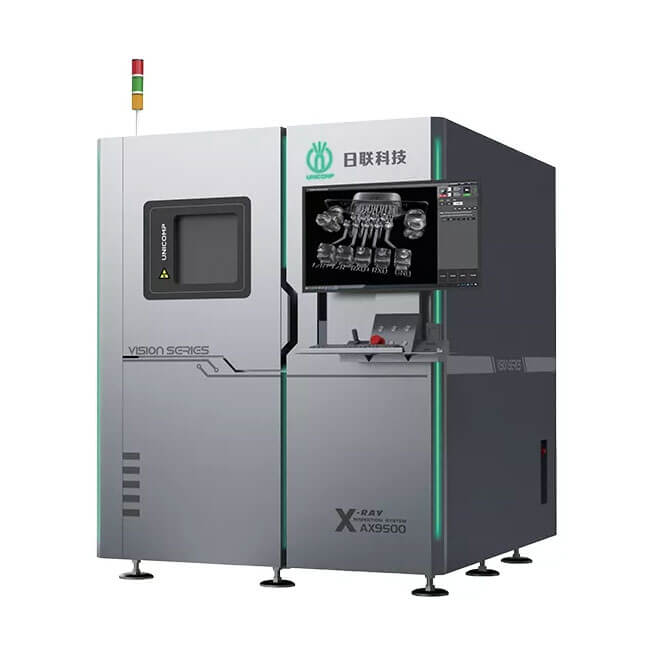

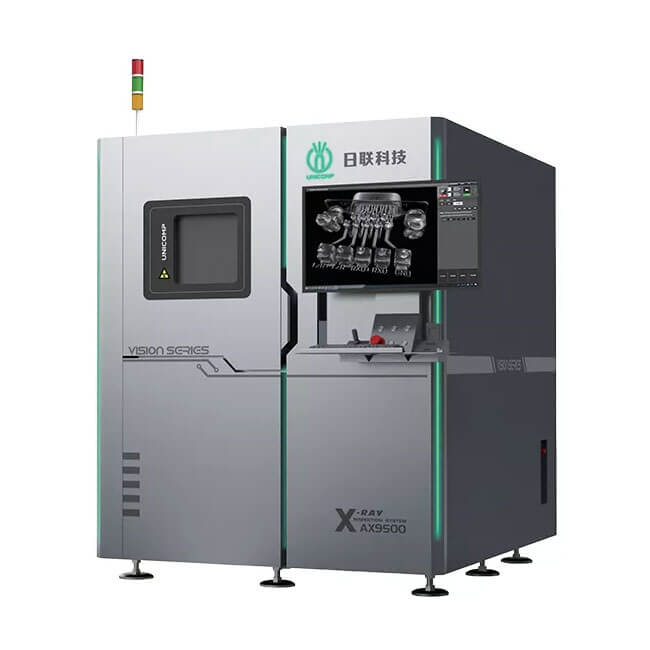

UNICOMP AX9500 CT SMT X-ray Inspection Machine

Fully upgraded new products, can perform CT detection on BGA, CSP, flip chips, LEDs and other semiconductors, can also be used for SMT welding analysis, 3D tomography CT scanning system (planar CT + cone beam CT)

Applications

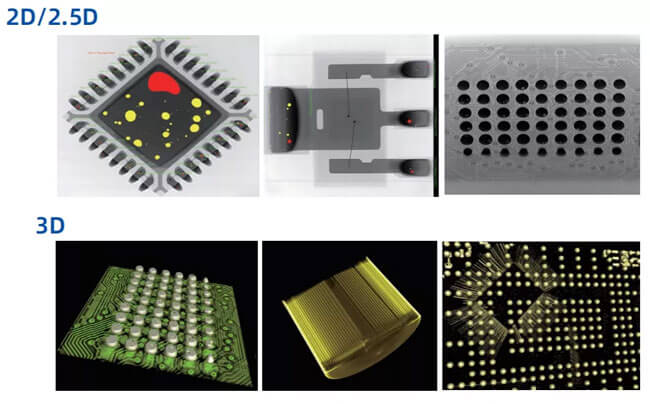

BGA、CSP、Flip Chip、LED Chip

Soldering Analysis

Automotive Devices, Battery Industry

Aluminum Die Casting, Molding Plastics

Ceramics, Other Dedicate Industries

Function Features

160kV open tube, 1µm focus spot

High resolution with Max detection area FPD

3D CT scanning system(Planar CT + Cone beam CT)

7 axis motion system, 360 degrees inspection

CNC programming with high accuracy and repeatability

High Definition navigation system

Easy tracking function with different angles

X-Ray images

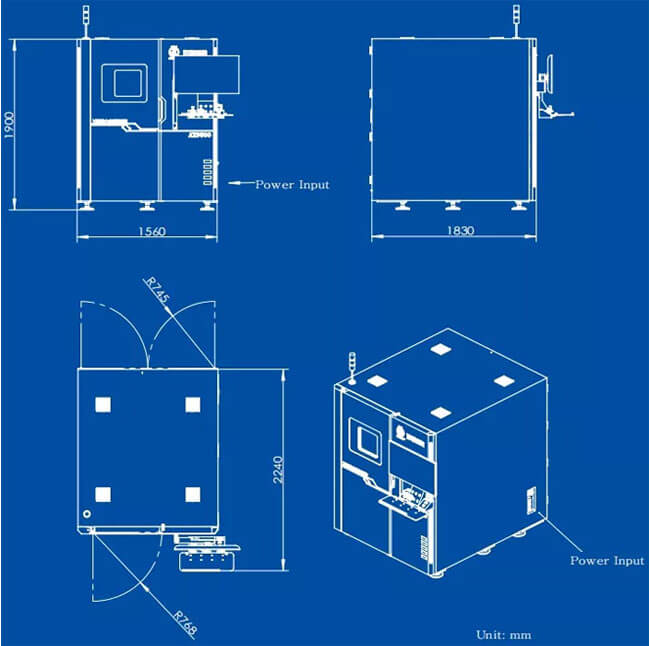

Dimensions and Appearance

System Parameters

Footprint Size

1560(W)*1830(D)*1900(H)mm

Machine Weight

≈3700kg

Max.Tube Power

64W

Max.Target Power

15W

Max.Voltage / Current

160kV/1000μA

X-Ray Leakage

<0.5μSv/h

Imaging System

X-Ray Tube Type

Open tube

Resolution

1 μm

Detector

FPD

System Magnification

2500X (combined 7500x)

Inspection Capbility

Maximum load size (2D/2.5D)

580(X)mm×610(Y)mm

Maximum Inspection Size(2D/2.5D)

540(X)mm×570(Y)mm

Maximum Load Size (CT):

Planer CT: 470(X)mm×500(Y)mm

Core-beam CT: 100(X)mmx200(Y)mm

3D Imaging Time

45s

Maximum Sample Weight

10kg(Planer CT)

0.5kg(Cone-beam CT)

Jacky

Jacky Jacky

Jacky