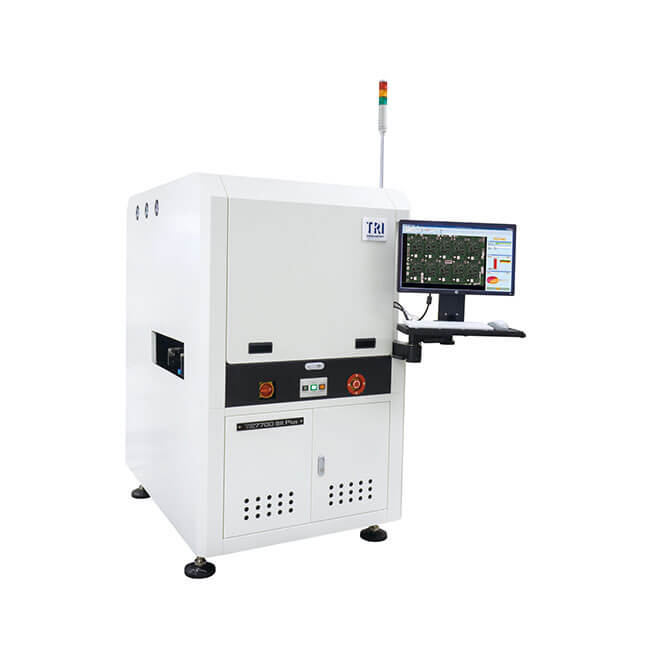

TRI TR7700 SII Plus AOI Machine

The World's First Hybrid AOI: TR7700 SII Plus

Utilizing a new hybrid inspection design, the TR7700 SII Plus can leverage both stop-and-go strategy and dynamic imaging to achieve optimal inspection performance on all types of PCBAs, e.g.: Inspection Cycle Time Reduction. Simply switch the inspection mode to determine the best approach for your product.

Features

• Flexible Stop-and-Go or Dynamic Imaging AOI

• Intelligent Easy Programming Interface

• Rapid Changeover with Intelligent Auto Conveyor

• Foreign Material and Extra Component Inspection

• 6 µm or 10 μm or 15 μm resolution

Specifications

| Imaging Method | Dynamic Imaging or Stop-and-Go on select configurations |

| Top Camera | 4 or 9 or 12 Mpix high speed color camera (factory setting) |

| Angle Camera | N/A |

| Imaging Resolution | 6 µm, 10 µm, 15 µm (factory setting) |

| Lighting | Multi-phase RGB+W LED |

| 3D Technology | N/A |

| Max. 3D Range | N/A |

| Inspection Performance | |

| Imaging Speed | 4 Mpix@ 10 µm Dynamic Imaging: 60 cm²/sec |

| 4 Mpix@ 15 µm Dynamic Imaging: 120 cm²/sec | |

| 9 Mpix@ 10 µm Dynamic Imaging: 72 cm²/sec | |

| 12 Mpix@ 6 µm Dynamic Imaging: 40 cm²/sec | |

| 4 Mpix@ 10 µm Stop-and-Go: 4.5 FOV/sec | |

| 4 Mpix@ 15 µm Stop-and-Go: 4.5 FOV/sec | |

| Motion Table & Control | |

| X-Axis Control | Ballscrew + AC-servo controller |

| Y-Axis Control | Ballscrew + AC-servo controller |

| Z-Axis Control | N/A |

| X-Y Axis Resolution | 1 µm |

| Board Handling | |

| Max PCB Size | TR7700 SII Plus@ 10 µm, 15 µm: 510 x 460 mm |

| TR7700 SII Plus@ 6 µm: 400 x 400 mm | |

| TR7700 SII Plus DL@ 10 µm, 15 µm: 510 x 310 mm x 2 lanes, 510 x 590 mm x 1 lane | |

| TR7700 SII Plus DL@ 6 µm: 400 x 310 mm x 2 lanes, 400 x 400 mm x 1 lane | |

| PCB Thickness | 0.6-5 mm |

| Max PCB Weight | 3 kg |

| Top Clearance | 10 µm, 15 µm: 25 mm [48 mm optional◎※] |

| 6 µm: 25 mm | |

| ◎The air blow module does not apply to this option | |

| ※This option is only available for 4 Mpix camera. | |

| Bottom Clearance | 10 µm, 15 µm: 40 mm [100 mm optional] |

| 6 µm: 40 mm | |

| Edge Clearance | 3 mm [5 mm optional] |

| Conveyor | Inline |

| Height: 880 – 920 mm | |

| * SMEMA Compatible | |

| Inspection Functions | |

| Component | Missing |

| Tombstoning | |

| Billboarding | |

| Polarity | |

| Rotation | |

| Shift | |

| Wrong Marking (OCV) | |

| Defective | |

| Upside Down | |

| Extra Component | |

| Foreign Material | |

| Solder | Excess Solder |

| Insufficient Solder | |

| Bridging | |

| Through-hole Pins | |

| Lifted Lead | |

| Golden Finger | |

| Scratch/Contamination | |

| Dimensions | |

| WxDxH | TR7700 SII Plus: 1000 x 1400 x 1650 mm |

| TR7700 SII Plus DL: 1000 x 1500 x 1650 mm | |

| Note: not including signal tower, signal tower height 520 mm | |

| Weight | TR7700 SII Plus: 600 kg |

| TR7700 SII Plus DL: 650 kg |

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky