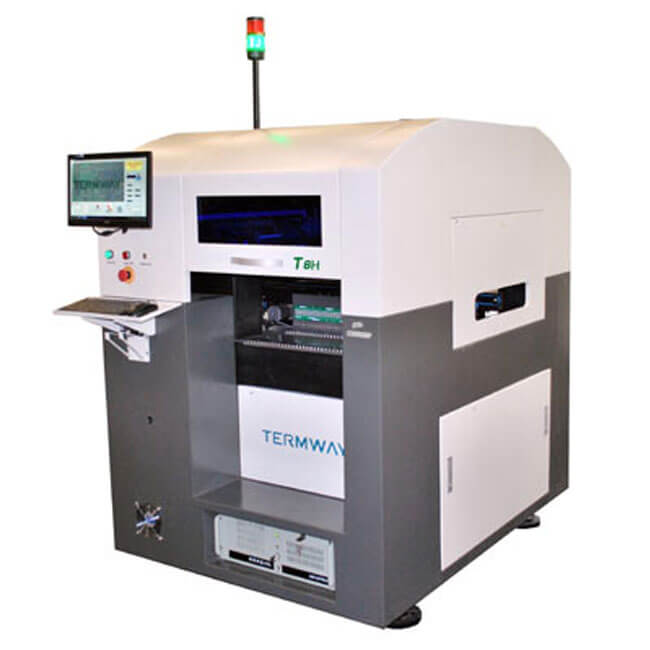

TERMWAY T8H Pick and Place Machine

Function introduction:

1.With super high precision moving platform technology which is made by integrated design of Natural granite. Make sure T8 can get to use for more than 10 years without any effect on moving precision. Meanwhile, integrated structure ensures a very excellent function in shock resistance.

2.World-class high-speed moving system ,with original imported high-accuracy ball screw and high-precision rail,ensuring the machine keep high-precision and stability after long time use.

3. The patented technology of non-stop scanning photos makes high-speed placement come true. Maximum vision mounting speed up to 18000 CPH.

4.Industry leading vision system :

Germany industrial digital cameras and high quality lenses is used,make sure the high quality and high accuracy.

5. automatic visual programming, it is no need to input the coordinates of components by manual, programming is simple, easy to learn for beginners and it is convenient and practical. It can universally import the PCB data, it is most suitable for mass production in middle scale.

6. Can be equipped with off-line programming software to achieve new product rapid import.

7. Intelligent board transmission system can automatically adjust the width and plywood.

8. High performance cost automatic pick and place machine, the most suitable for mass production;

9. Standard configuration of automatic nozzle replacement system, it can freely change 12 different nozzles.

10.Standard configuration of automatic inspection function for height of board and picking failure alarm function,It improduction quality .

11. Standard configuration of component missing alarm function it realizes no keeper nearby machine when mass production.

T8H Introduction :

1.Can mount up to 114 kinds of components at most.

2. Standard configuration can mount SMD 0201 and above size.

3.The max size of QFP :48*48mm.

4. Can mount BGA ,CSP and QFP with pitch no less than 0.4 mm.

5.Machine can be configured with first component electronic detection function, to ensure all the places components are correct.

Technical Parameter :

Model

T8H

Mounter head

8 heads

Max PCB board

400×350mm

Max move range

600×450mm

Z axis move range

20mm

Typical speed

8000-15000cph

Theoretical Max mount speed

18000 cph

Moving System

XY axis Japan panasonic servo motor driver + Ground ball screw

X.Y axis precision

±0.0015mm

Repeat mount precision

±0.015mm

Programme method

Visual Position

Component available

Above 01005 below 38mm IC

Programme method

Automatic data import/Video learning/Keyboard input/ Off-line programming software

Feeder

8mm,12mm,16mm,24mm,32mm、44mm GF feeders (Optional)

Feeder NO.

If place GF feeder, Can be put 72 pcs of 8MM GFTA-08S feeder,

If place DF feeder, can mount 144 kinds components.

If place CF feede ,Can be put 80 pcs of 8MM CF feeder

IC tray NO

when put on two ic tray,Max PCB board 340*240mm

If configure TF-28 IC feeder cart ,can finish the mounting of 28 kinds of IC

Operation system

WINDOWS XP/ WIN7

Compressed air

80psi(0.5Mpa),gas flow 80L/M

Power

220v,50Hz,4kw

Weight

860kg

Dimension

1200×1860×1530mm

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky