HCT T100 Pick and Place Machine

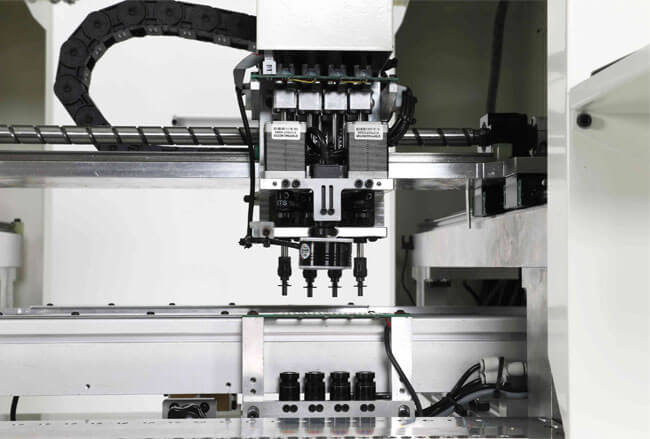

HCT-T100 Small 4 Heads SMD Pick and Place Machine

The major benefit of employing SMT machines for LED manufacturing is that hand assembly variations are completely eliminated. Multiple components are placed on the board simultaneously by the accurate and very accurate automatic led pick and place system, greatly increasing production and lowering labor costs. As human participation has been reduced, the efficiency of SMT-based LED component manufacturing has grown tremendously.

Product Features - Mini 4 Heads SMD LED Pick and Place Machine

1. Bottom Vision Alignment System.

2. Fiducial recognition and coordinate correction.

3. Conveyor system with SMEMA interface and automatic width control.

4. Perfect for proofing of production.

5. Optimized pick/place routing design, ensures precision.

6. Works with different types of the high-precision nozzle.

7. Suit for a variety of SMD components: resistors, capacitors, IC, SOP, QFP, QFN, SOT, etc.

8. Using imported high-precision ball screws, motors, solenoid valves, cables, etc., effectively improves placement accuracy, and stability.

APPLICATION AREA

SMT Proofing use & Laboratory use; Small batch production; University teaching use; R&D customization; Personal entrepreneurship; processing on giving materials; etc.

Advantages of the SMT Process for LED Pick and Place

The biggest advantage of using SMT machines for LED is that it eliminates the possibility of variations common to manual assembly. The precise and high-precision automatic led pick and place machine places multiple components on the board at once, dramatically increasing productivity while reducing labor costs. The efficiency of SMT-based LED component manufacturing has increased exponentially as a human intervention has been minimized.

In addition, to pick and place-led manufacturing, the importance of the SMT process for led pick and place is also reflected in the design process. Miniaturization is the trend in LED lighting, and the pick-and-place SMD-led mounting machine makes this possible. The LED SMT machine utilizes higher levels of automation, high-quality nozzles, and feeders, all of which combine to allow the handling of much smaller components than traditional assembly methods.

Another important aspect of the SMT LED machine that helps achieve compact dimensions is the use of zero wires. This process reduces the size of the board by mounting the components directly onto the board, resulting in a compact and slim design.

Product Display - Mini 4 Heads SMD LED Pick and Place Machine

Technical Parameters

Model

HCT-T100

Number of Heads

Fixed Bottom Vision

4

Placement Rate

Under the optimum condition

6000CPH

IPC9850

5000CPH

Feeder Capacity

Front and Back

18 Tape Feeders (Electric standard)

18+18 Tape Feeders(Optional)

25+25 Pneumatic Feeders (Optional)

IC Tray Capacity

325 x 135mm

1

Component Alignment

Vision Detection

Component Sizes

Handled by Fixed Small Camera

Smallest: 0402 (inch)

Largest: 6 x 5 (mm)

Max. Height: 15mm

Handled by Fixed Big Camera(Optional)

Smallest: 5 x5 (mm)

Largest: 20 x 20 (mm)

Resolution

X/Y Axis

Ball Screw + Servo Motor

Z Axis

Step-Servo Motor

Rotation

0 to 360°

Placement Accuracy

±0.05mm

X-Y Repeatability

Ball Screw

±0.02mm

PCB Size

Maximum

L 300 x W 250mm

Minimum

L 50 x W 50mm

Programming

Vision Teach-in

Coordinates Import

Main Control

Industrial PC

Power

AC 220V±10% (50/60Hz, 1 phase)

Max. 1.5KW

Air Pressure

0.55-0.7MPa (5.6-7.1kgf/cm2)

External Dimension(mm)

L x W x H

700 x 900 x 1300 mm

Mass

Approximate 150kgs

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky