SPEA 4020 S2 Flying Probe Tester

Key Features

Best measurement accuracy

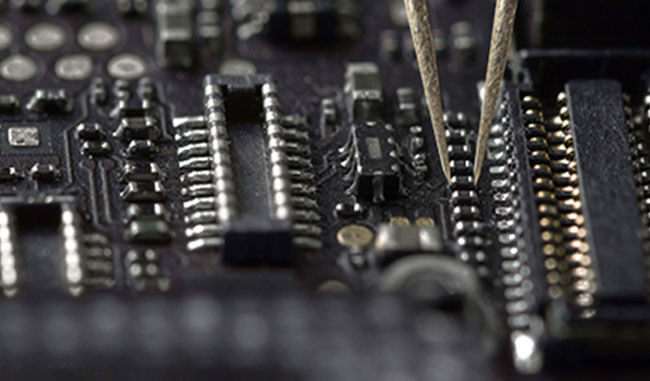

Accurate Micro-SMD contacting

No cost of fixturing

Intuitive programming

Zero errors at functional test

Field returns are practically eliminated

Features

Accurate micro-SMD probing

Miniaturization won’t stop and SPEA’s Flying Probe systems are ready for the future.

Top-performance linear optical encoders on XYZ axis

Micro-SMD (008004) pad accurate contacting

Reliable test of flexible/thin printed circuits, Sticky Boards

Positioning measurement stability over long time

Ultra-Fast Soft-Touch technology: no touch damage, no stress on PCB and Micro-SMD

Best Measurement Accuracy

Highest measurement performance & accuracy (0.1pF)

Signal integrity

No measurement degradation or interference

Immediate signal acquisition (within hundreds of microseconds)

Fast Probe Speed

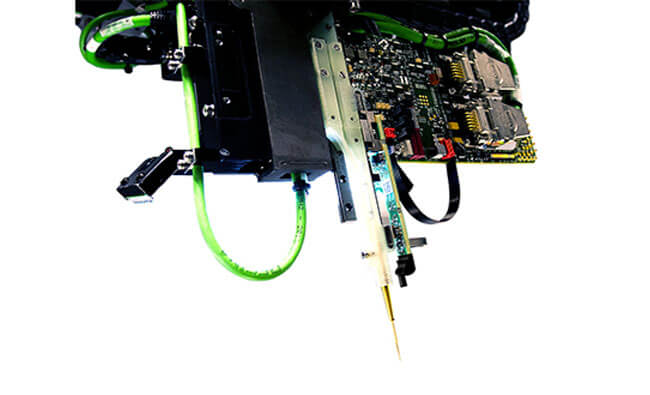

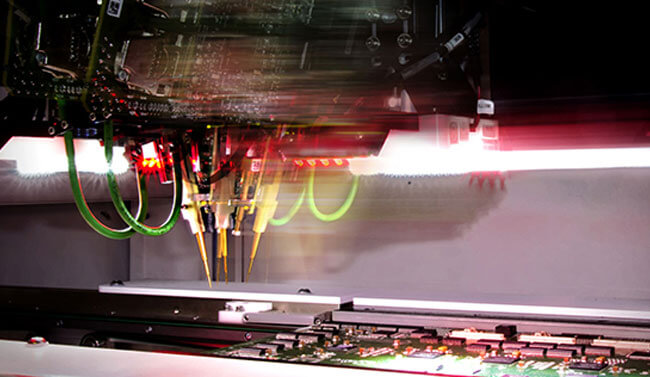

Top-performance linear motors on XYZ axis

Highest speed of movement

Maintenance-free: no tear and wear can affect accuracy

Mechanical stability over time

Multi-Mode Probing

4020 S2 can combine the 4 high-speed top flying heads with additional tools to contact the bottom side of the board, increasing throughput and test capabilities.

Each flying probe can be used for in-circuit test, power-on test, sink/source analog, digital D/S, flashing via on-board programming, boundary scan, prescaler.

While using the 4 top probes to perform flying probe test from the top side, a bottom lifted platform can be used for bed-of-nails fixtures, multiple high-current power supplies, digital I/O, high-speed signals, fixed probes, planarity supports.

Leonardo OS2

Easy. Fast. Self-programming.

Automatic test program generation in minutes

Automatic test program generation with or without CAD file

– 50% test program generation time with new S2 System Control

Faster & fully automatic Debug & Tuning

Automatic board repair software

Automatic Pick & Place X-Y file import

Built-in Self-Test (BIST) compliant

User-friendly intuitive graphical interface

Control software to monitor, analyze & optimize the production process

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky