SKAI 3Si-MS2 L size 3D SPI Machine

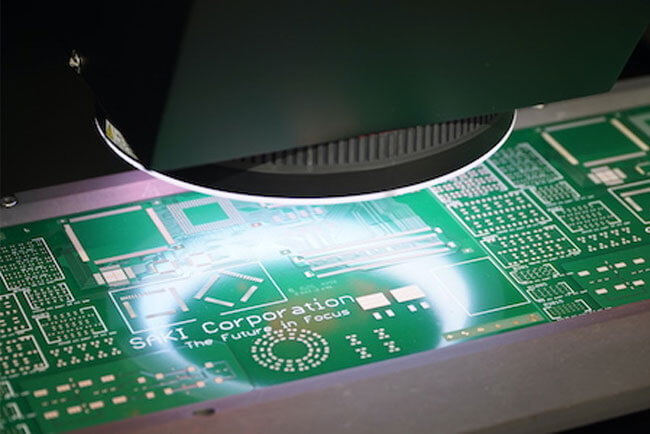

Saki’s high-speed, high-precision 3D-SPI machines specialize in the inspection of SMT process solder printing. 3D-SPI machines inspect and analyze a wide range of potential problem points, including the measurement of solder paste area, height, and volume; as well as bridge, solder horn, and BGA coplanarity compliance.

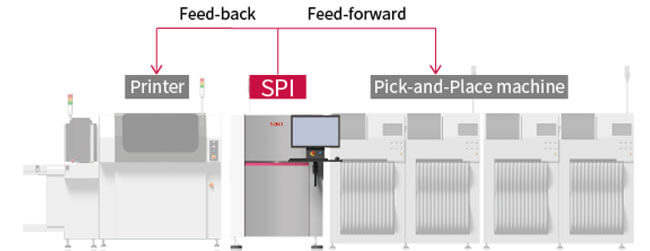

The quality of the entire production line is ensured through machine-2-machine co-ordination with solder printing and pick-and-place machines.

High-Speed Inspection

The industry’s fastest inspection of micro component pads

Unique high-speed image data processing technology

Hardware designed for high-speed and high-accuracy inspection

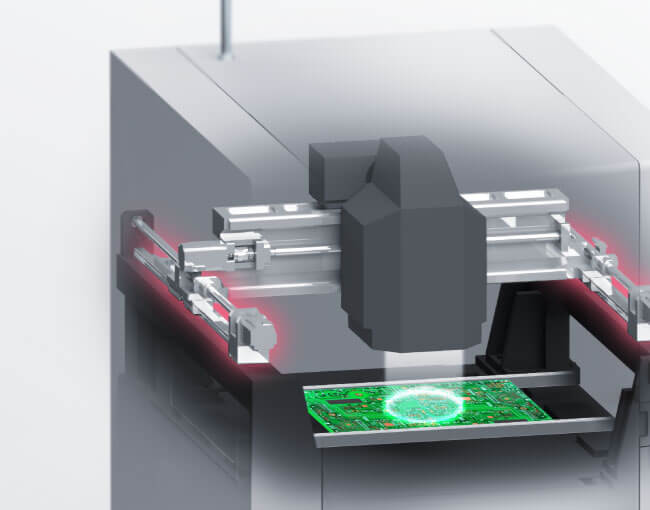

The design employs an ultra-rigid gantry and biaxial drive with an ultra-high-definition linear scale, enabling high-speed movement of the optical head with incredible stopping position accuracy.

Faster data processing thanks to Saki’s unique dedicated software

All imaging and processing software is developed by Saki in-house, improving hardware optimization and inspection algorithms – leading to faster, superior data processing.

High Accuracy Inspection

Innovative hardware structure

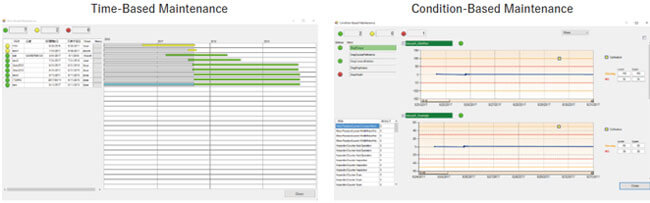

Comprehensive self-diagnostics

High-accuracy, high-quality and versatile solder print inspection

Robust hardware structure that guarantees an extended lifetime of continued high-quality inspection

With its ultra-rigid gantry, biaxial drive, and ultra-high-definition linear scale, the 3D-SPI has high repeatability and contributes to maintaining the stability and quality of inspection result data. Stable inspection is guaranteed thanks to the strong, durable frame that provides reliability for 15 years and beyond.

Self-diagnostic system

The self-diagnostics monitor equipment status in real time. Hardware checks during startup and prior to inspection greatly reduce the risk of sudden failures, and combined with consumable monitoring, allows maintenance to be efficiently scheduled with minimal downtime.

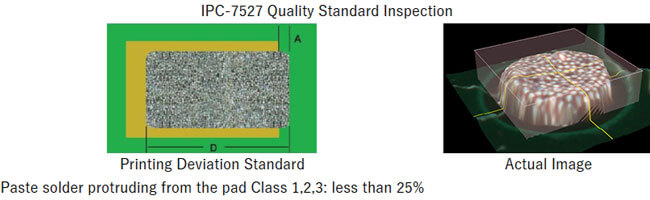

Solder print inspection algorithms

IPC-compliant inspection quality

Positional deviation of pad size is inspected based on the IPC-7527 quality standard for measurement allowances.

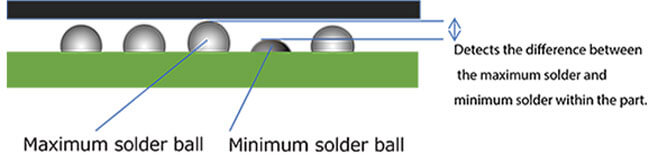

Coplanarity inspection

High I/O count device inspections benefit from improved coplanarity, with solder range analysis for height, volume and area that helps prevent post-reflow wetting.

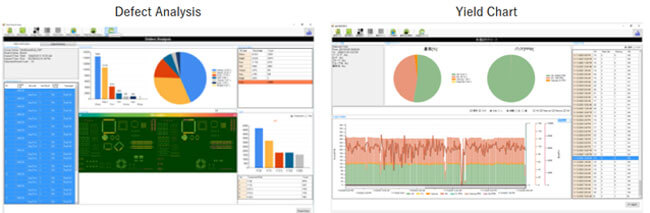

SPC functions for visualization of solder quality

Solder quality is managed and maintained through comprehensive monitoring of board solder amounts and defect trend analysis. Extensive reporting functions and data analysis tools allow for export of defect type rankings and yield charts.

Saki’s M2M Solution

Feed-back from SPI to screen printer

Feed-forward from SPI to pick-and-place machine

Feed-back from SPI to screen printer

The accuracy of solder printing is improved thanks to feeding back solder printing position misalignment data from the SPI to the solder printing machine. Additionally, metal mask cleaning instructions are automatically communicated to prevent solder printing defects.

Feed-forward from SPI to pick-and-place machine

Component mounting position is corrected by sharing information on solder printing position misalignment with the pick-and-place machine. Additional data on failed sub-boards is also communicated to avoid mounting components in these instances.

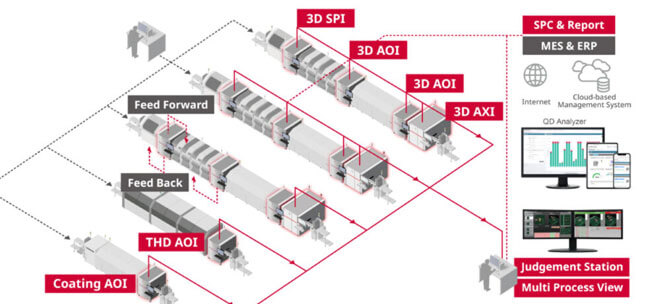

Saki’s Total Lineup Solution

Saki’s 3D-AOI uses a common platform with 3D-SPI and 3D-CT-AXI. The process is consistent throughout – from post-printing solder inspection using SPI, through to the inspection of mounted components.

Specification

|

Dimensions |

M |

L |

XL |

|

Model |

3Si-MS2 |

3Si-LS2 |

3Si-ZS2 |

|

Size |

850 × 1430 × 1500 |

1040 × 1440 × 1500 |

1340 × 1440 × 1500 |

|

(W)×(D)×(H)mm (in.) |

(33.46 x 56.30 x 59.06) |

(40.94 x 56.69 x 59.06) |

(52.75 x 56.69 x 59.06) |

|

Resolution |

12μm、18μm |

18μm |

|

|

PCB Clearance |

Top: 40mm(1.57 in.) Bottom: 60mm(2.36 in.) *1 |

||

|

Electric Power Requirement |

Single-phase ~ 200-240V +/-10%, 50/60Hz |

||

|

PCB Size |

50 x 60 – 330 x 330 |

50 x 60 – 500 x 510 |

50 x 60 – 686 x 870 |

|

(W)×(L)mm (in.) |

(1.97 x 2.36 – 12.99 x 12.99)*2 |

(1.97 x 2.36 – 19.68 x 20.07)*3 |

(1.97 x 2.36 – 27.00 x 34.25) |

|

Inspection Item |

the measurement of solder paste area, height, and volume, bridge, solder horn, and BGA coplanarity compliance. |

||

*1 For dual mode, the PCB Clearance Bottom is 50mm (1.96 in.),

*2 For dual mode, the PCB Size is 50×60〜320×330 (1.97 x 2.36 – 12.60 x 12.99)

*3 For dual mode, the PCB Size is 50×60〜320×510 (1.97 x 2.36 – 12.60 x 20.07)

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky