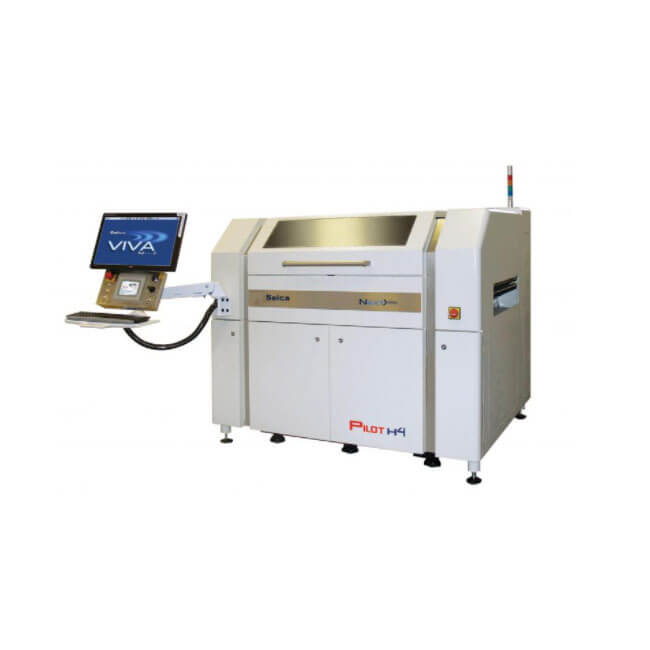

Pilot H4 flying needle online measurement horizontal single-sided 4-pin

The Pilot H4 Next series automatic version is a solution for fully automated flying needle testing, without the need for constant operator presence to manage the test system. Thanks to the integration of a transmission system compatible with the SMEMA protocol, the Pilot H4 Next series can be integrated with an automatic loading and unloading device for circuit boards or combined with a complete assembly line to perform circuit, functional and visual tests on electronic boards in a fully automated mode. This is the ideal solution for medium or even high volume production testing needs. The large test area can accommodate 21 "x 24" boards (540 x 610mm) and double-sided split tests. The ATE rack can be expanded by up to 1032 analog channels and can be connected to an optional external needle bed test fixture (TPM).

Product Description

The Pilot H4 Next series automatic version is a solution for fully automated flying needle testing, without the need for constant operator presence to manage the test system. Thanks to the integration of a transmission system compatible with the SMEMA protocol, the Pilot H4 Next series can be integrated with an automatic loading and unloading device for circuit boards or combined with a complete assembly line to perform circuit, functional and visual tests on electronic boards in a fully automated mode. This is the ideal solution for medium or even high volume production testing needs. The large test area can accommodate 21 "x 24" boards (540 x 610mm) and double-sided split tests. The ATE rack can be expanded by up to 1032 analog channels and can be connected to an optional external needle bed test fixture (TPM).

Pilot H4 Next series automatic version applies:

· Mass production

Parametric and non-vector vectorless testing

Power-up test of UUT

Board DFT (allows access on one side only)

· Medium/high yield, multi-species products

· Distinguish the placement of defective products

· Characteristics

Test system with 4 flight probes on top

· Integrated automatic conveyor

No vector vectorless test of digital components, ICT test

· "QuickTest" graphical functional test programming software

In-board programming, boundary scan testing, optical testing

In addition to the flying electrical probe, fixed channel expansion fixture and power-on device can be installed.

· Offline programming and maintenance station

· Barcode and two-dimensional code reading management

• Automatic statistics collection

· Automatic programming through CAD data import

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky