Nordson SE3000-DD™ & SE3000-D™ SPI Machine

Provides flexibility to further increase productivity with high volume throughput, while relying on the unprecedented combination of speed, accuracy and ease-of-use of the SE3000 3D SPI.

Overview

Metrology Grade Accuracy at Production Speed

The SE3000 DD SPI system offers unmatched accuracy with the revolutionary MRS® technology by meticulously identifying and rejecting reflections caused by shiny components and reflective solder joints. Effective suppression of multiple reflections is critical, making MRS an ideal technology solution for a wide range of applications including those with very high quality requirements.

CyberOptics has advanced the proprietary Multi-Reflection Suppression (MRS) sensor to an even finer resolution. The Ultra-High Resolution MRS sensor enhances the SE3000 DD platform, delivering superior inspection performance, ideally suited for the 0201 metric process and micro-electronic applications where an even greater degree of accuracy and inspection reliability is critical.

Flexibility at Its Best

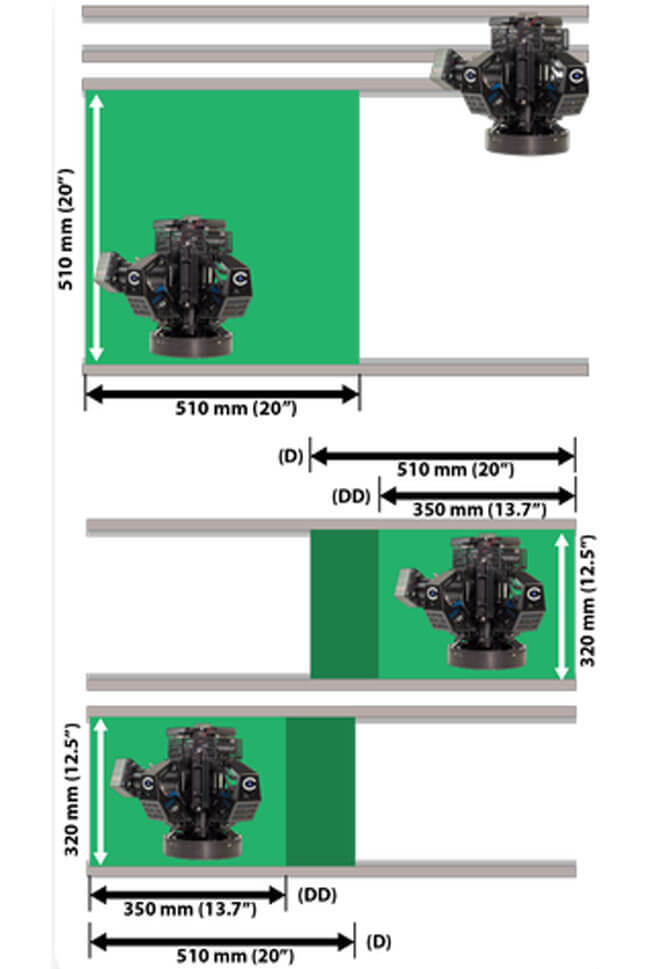

The SE3000 DD 3D Solder Paste Inspection (SPI) System is an extension of the award-winning SE3000™ 3D SPI platform. The dual lane, dual sensor system maximizes flexibility catering to varying PCB widths. This unique design provides the ability to inspect high volume assemblies, the convenience of inspecting different assemblies and board sizes simultaneously on different lanes, or even switching from dual lane to single lane mode to inspect very large boards.

Not only does the SE3000 DD provide PCB flexibility, it also provides the flexibility to choose two of the same or two different proprietary MRS sensors.

Fast, Smart, Easy-to-use software

The SPI V5 series software delivers world-class user experience with its intuitive interface, completely changing the way users interact with our system. With full multi-touch experience, SPI V5 series software offers a range of revolutionary features that enable smarter and faster inspection.

Flexibility at Its Best for Increased Throughput

With a smaller footprint than 2 SE3000 standard systems, the dual lane, dual sensor SE3000-DD features a smart conveyor design solution providing maximum flexibility to cater to varying PCB widths. This unique design gives you the convenience of inspecting different board sizes on different lanes or even switching from dual lane to single lane mode to inspect very large boards. With SE3000-DD, you can also quickly inspect different programs on different lanes as well as perform synchronous or asynchronous inspection.

Specifications at a Glance

Inspection Speed

Standard MRS Sensor: 35 cm²/sec (2D+3D)

Ultra-High Resolution MRS Sensor: 15 cm²/sec (2D+3D)

PCB Size (Max.)

SE3000 DD:

SE3000 D:

Single Lane: 510 x 510 mm (20 x 20 in.); Dual Lane: 350 x 320 mm (13.7 x 12.5 in.)

Single Lane: 510 x 510 mm (20 x 20 in.); Dual Lane: 510 x 320 mm (20 x 12.5 in.)

Field of View (FOV)

Standard MRS Sensor: 36 x 36 mm

Ultra-High Resolution MRS Sensor: 21 x 21 mm

Resolution

Standard MRS Sensor: 18µm

Ultra-High Resolution MRS Sensor: 9µm

Minimum Component Size

Standard MRS Sensor: 0402 mm (01005 in.)

Ultra-High Resolution MRS Sensor: 0201 mm (008004 in.)

Component Height Clearance

Top: 50 mm (1.96 in.) ; Bottom: 30mm (1.18 in.)

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky