Nordson MXI Ruby XL X-ray Inspection Machine

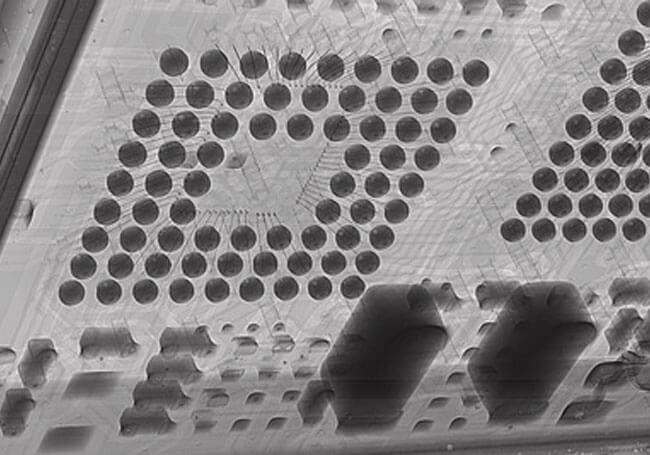

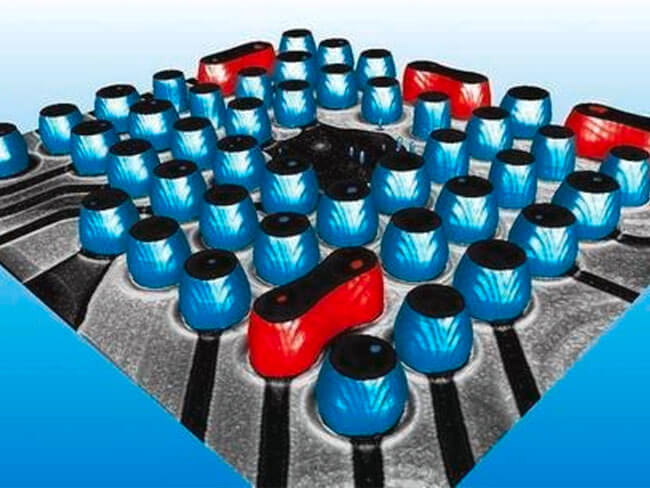

Designed for the largest PCBs, Ruby XL allows 840 x 615mm (33” x 24.2”) areas to be inspected non-destructively, with feature resolution up to 0.5 µm.

Overview

Ruby XL X-ray inspection system is the optimum solution for large boards. The unique Nordson TEST & INSPECTION NT maintenance-free, sealed-transmissive X-ray tube, providing 0.5 μm feature recognition and up to 20 W of target power, together with the 3 Mpixel long lifetime CMOS flat panel detector makes this jewel of a system cover all the failure analysis and manufacturing tasks required in the production environment.

Sizes

Maximum board size: 47” x 26.4” (1205 x 672 mm) with reduced magnification

• Maximum inspection area: 33” x 24.2” (840 x 615mm)

• 70° oblique angle views (over 30” x 24”, 762 x 610 mm):

– for 360° around a point of interest

- isocentric manipulator configuration keeps features in field of view

Advantages

Nordson TEST & INSPECTION NT500 Maintenance-Free, Sealed-Transmissive X-ray Tube

• 0.5 μm Feature Recognition

• 160 kV Tube with Up to 20 W Target Power • Always Retains

Sub-Micron Ability

• Nordson T&I 3 Mpixel @ 25fps Long Lifetime CMOS Flat Panel

Detector with Real Time Image Enhancements

• Geometric Magnification 1,800 X, System 7,800 X for Total 23,400 X with Digital Zoom

High Magnification Inspection

The vertical system configuration, with the x-ray tube sitting below the isocentric ‘move and tilt’ of the detector, all controlled through simple, joystick-free, ‘point and click’ operation, provides the safe, collision-free and high magnification inspection required for production applications. All these tasks can be simply and quickly automated from within the Nordson T&I ImageWizard software without the need for programming skills. Optional upgrades include X-Plane™ and joystick control.

Crystal Clear X-ray Inspection!

Specifications at a Glance

Technical Data- Ruby XL

|

Dimensions ( mm) |

|

|

Approx. Size |

94.5" x 98.5" x 81.5" (w x d x h) |

|

|

2400 x 2500 x 2070 mm (w x d x h) |

|

|

|

|

Weight |

|

|

Total system weight |

3000 kg (6600 lbs) |

|

Max. Power Consumption |

10 kg (22 lbs) |

|

|

|

|

Power Supply |

|

|

Single Phase |

~ 200 - 230Vac, 16A |

|

Max. Power Consumption |

1000 W |

|

|

|

|

Climatic conditions |

|

|

Operating temperature |

10 °C to 30 °C |

|

Air humidity |

< 85 % |

|

|

|

|

Compressed Air |

|

|

Compressed Air |

4-6 bar of clean dry air for anti-vibration |

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky