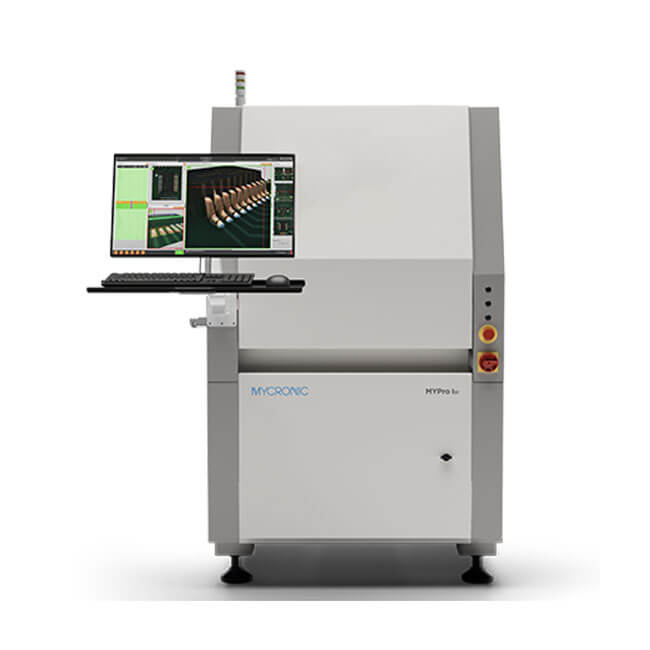

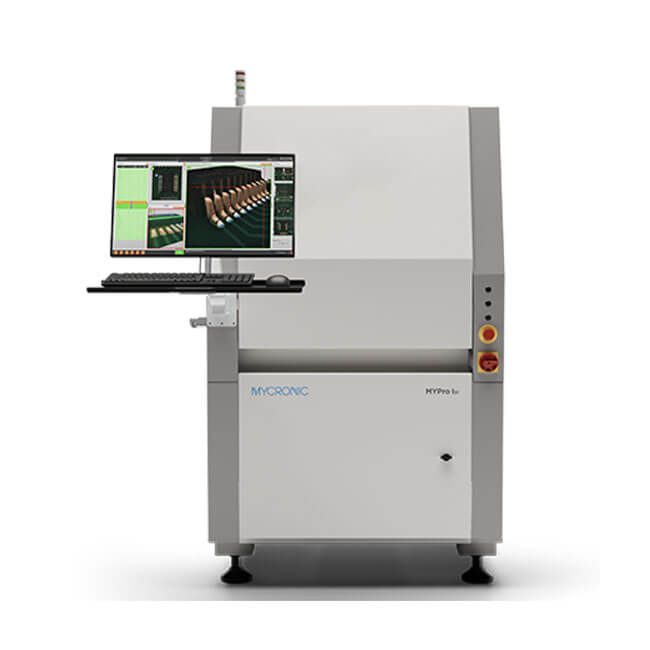

MYCRONIC MYPro I51 3D AOI Machine

AIAI-powered interface for fast and reliable programming

FastUp to 30% faster cycle times

AccurateBest-in-class accuracy

High-performance 3D AOI just got faster and sharper

The MYPro I51 takes the performances of Mycronic 3D AOI technology to new heights with up to 30% faster processing time and enhanced accuracy, without compromise. Equipped with Iris™ 3D vision technology, the latest generation of 3D AOI sensor, the MYPro I51 inspects up to 30% faster than previous generation while doubling the number of pixels. The result is a real breakthrough in inspection cycle times keeping pace with the most demanding lines in the industry, and an increased test coverage with the ability to inspect 008004 (0201 metric) component packages.

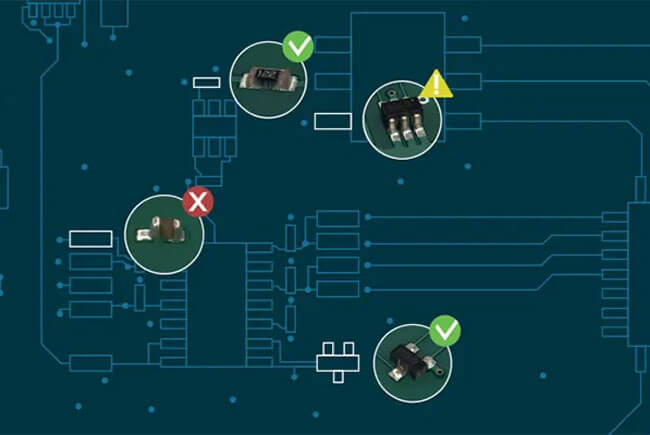

MYWizard, a game changer in 3D AOI programming

To guide operators through programming, the new MYWizard user interface integrates two artificial intelligence systems – Auto-Matchmaker, an advanced component recognition technology, and new machine learning algorithms that inspect fiducials and component’s polarity. It results in up to 30% reduction in programming time compared with previous generations, with reduced programmer experience and training.

Escape Tracker for automated performance optimization

Industry first

Next-generation self-checking system for inspection performances

With Escape Tracker, the operator is immediately informed of any errors or programming weaknesses that could potentially generate false calls or escapes during production. Fine-tuning is made much simpler, faster and more efficient regardless of production conditions or programmer skill levels.

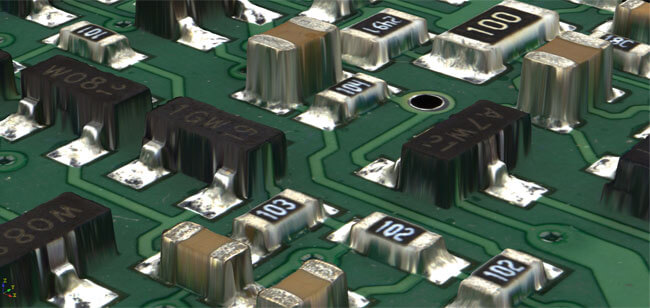

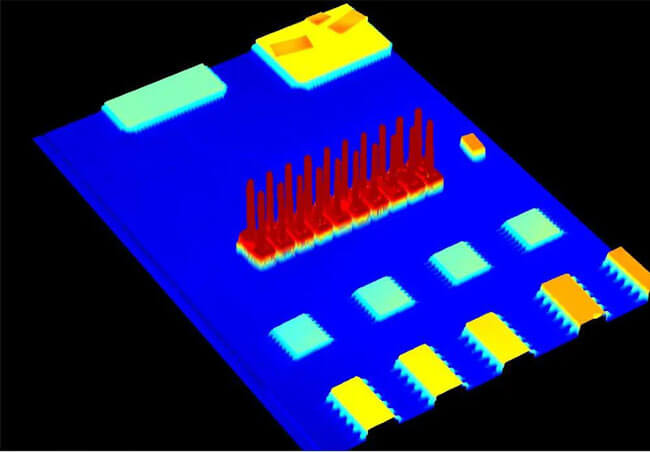

Iris™ 3D vision technology

Faster. Sharper. Smarter.

High-performance inspection. Accelerated.

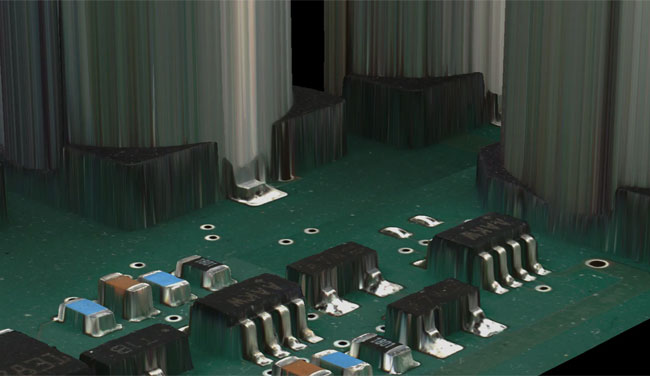

The next generation of automotive and industrial electronics demand next-generation inspection technologies. The Iris 3D vision technology pushes the limits of high-performance AOI to offer the industry’s most precise metrology and complete test coverage even at the most demanding takt times.

Sharper 3D imaging

Industry-leading performance and production stability

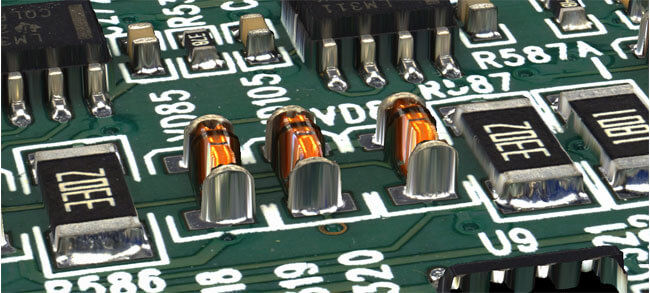

The MYPro I series offers best-in-class accuracy and repeatability in X, Y, Z and Theta for efficient process control. The unique combination of sub-pixel geometric pattern matching technology, proprietary 3D algorithms and unique warpage and distortion compensation leads to superior critical measurement capabilities.

Vectoral imaging pattern matching.

+/- 5 mm warpage compensation with full Z accuracy.

3.5 μm X,Y resolution with sub-pixel technology

Constant 1 µm Z resolution, from -5 up to 20 mm in altitude

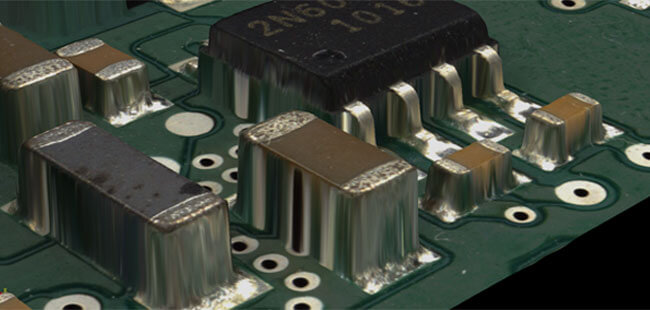

All-in-one inspection capabilities

With full test coverage, the MYPro I series measures the component body, leads, and solder joints with the utmost accuracy to catch any type of defects.

Its comprehensive toolbox of ready-to-use 2D and 3D inspection tests allows the MYPro I series to inspect not only all SMT components, but also through-hole components, press-fit components, connectors of all types and shapes, and any new packages.

The board geometry and relative positions of components, pins, or connectors can also be inspected with metrological precision to further expand your test coverage and production quality.

Fully integrated process control

MYPro Link

MYPro Link, Mycronic’s award-winning web-based process control software suite, puts the benefits of inspection data correlation into real-time production. All so you can monitor your line performance over time or at a glance and get to the root cause of every defect in just a few clicks.

MYPro Analyze

Monitor your process in real time with MYPro Analyze: accurate production data help you optimize your performance and give you meaningful information to further improve and maximize first-pass yield.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky