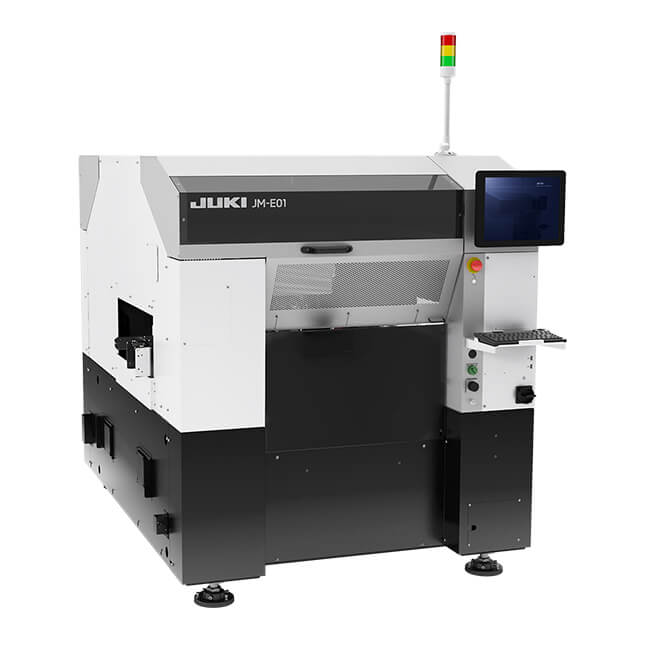

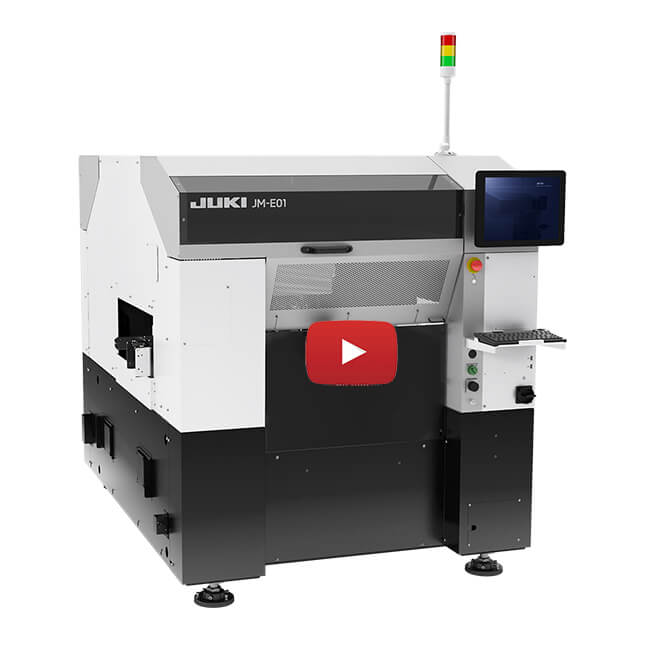

JUKI Multitask Platform JM-E01 Automatic Insertion Machine

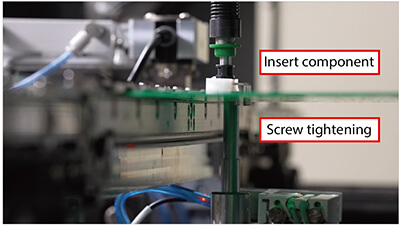

- Component insertion×Screw tightening

- Automate 2 processes simultaneously!

- A further evolved Multitask Platform

Features

- High efficiency

One unit can insert component and screw tightening

This highly versatile machine realizes component inserting work, screw fastening work, and multi-process automation. The board size is 800mm x 560mm*¹, and the weight is up to 10kg*².

*1 At double feed: standard

*2 Option

One unit can insert component and screw tightening

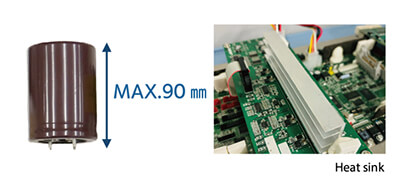

- High Flexbility

Wide component range from small to large and heavy

XY shaft construction adopted. By setting head unit axis to 2 axes, the compatible component size has been expanded. Component height is 90mm*, component heavy 400g, and insertion force up to maximum 50N.

*Component body 80㎜ or less, lead + body = 90㎜ or less

Supports large and heavy component

Component size : Max.□150.0㎜

Component height : Max.90㎜*

Component weight : Max.400g

*Component body 80㎜ or less, lead + body = 90㎜ or less

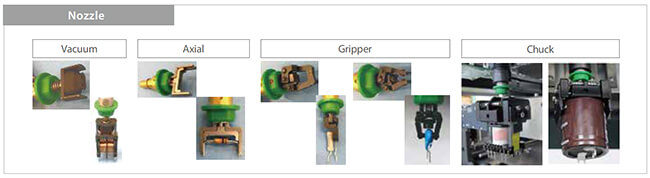

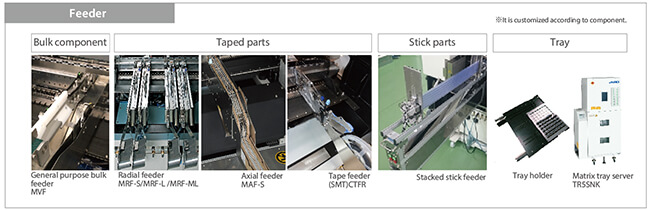

- Large variety of feeders and nozzles

- High quality

- High quality

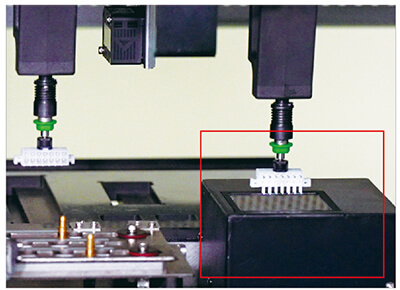

High-precision insertion is realized by image recognition using inspection machine technology

By applying JUKI’s unique 3D image-recognition technique, the leading edge of the lead can be recognized more accurately. It also enables lead recognition with a pointed tip, semicircular tip, and difference in height, enabling high-precision insertion of a wide range of insertion component.

3D inspection

Prevents scratches and misalignment of PCB and component

Screws can be tightened from under the board. Since the board does not need to be turned over, it prevents scratches and misalignment on the board and component and reduces losses.

| JUKI Multitask Platform JM-E01 Automatic Insertion Machine | |

| Board size(㎜) | 1Single clamping:50×50~410×560 Double clamping:50×50~800×560 |

| PCB weight | 6kg(standard)10㎏(option) |

| Component height | Component body 80㎜ or less, lead + body = 90㎜ or less |

| Component size(mm) | Outer dimension (package) size □150mm |

| Recognition size once:40×25, 4×1:150×25, 4×2:150×48, 4×3:150×71 | |

| Applicable screw size | M3 size*2 |

| Screw supply method | Force-feed type |

| Machine dimension(mm) (W×D×H) *1 | 1,500×1,930×1,600 |

| Body weight | 2,000kg |

*1 For 900mm conveyor

*2 Please contact for detail

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky