JUKI JM-50 Automatic Insertion Machine

Reliable, high quality automatic insertion with unmatched value

* Ideal for high-mix low-volume production

* New, flexible feeders increase component range providing superior productivity and faster changeover

* Huge variety of applications

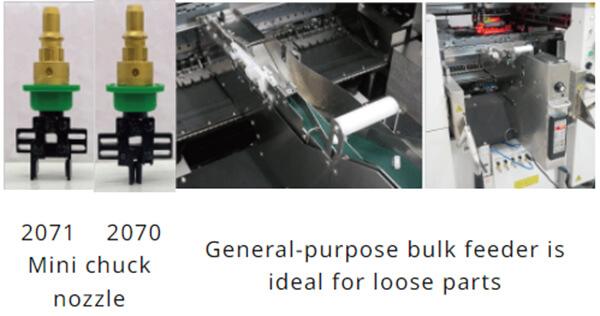

* New Mini Chuck Nozzles support a wide range of components, reducing cycle time, decreasing tooling costs, and simplifying programming

* Largest installed base thanks to high quality and unmatched reliability

Streamline Your Production with JUKI JM-50

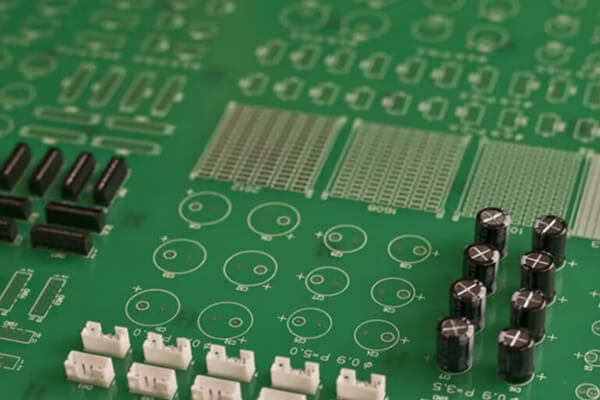

- The JUKI JM-50 automatic insertion machine is a versatile and cost-effective manual insertion machine designed to tackle the challenges of high-mix, low-volume production environments. Its innovative features and user-friendly design make it an ideal choice for businesses seeking to enhance their productivity and efficiency.

- Unleash Enhanced Productivity

At the heart of the JM-50 PCB insertion machine lies its newly developed nozzles and feeders, which work in tandem to simplify setup, expand component range, and elevate overall productivity. This translates into faster changeovers and a streamlined production process, keeping your operations running smoothly.

- Versatility Meets Affordability

As JUKI’s entry-level THT machine, the JM-50 THTpick and place machine strikes the perfect balance between affordability and capability. Despite its cost-effective nature, it packs a powerful punch, boasting the ability to handle a wide range of components, making it a versatile asset for any production line.

Features

- Ideal for high-mix low-volume production

- New, flexible feeders increase component range providing superior productivity and faster changeover

- Huge variety of applications

- New Mini Chuck Nozzles support a wide range of components, reducing cycle time, decreasing tooling costs, and simplifying programming

- Largest installed base thanks to high quality and unmatched reliability

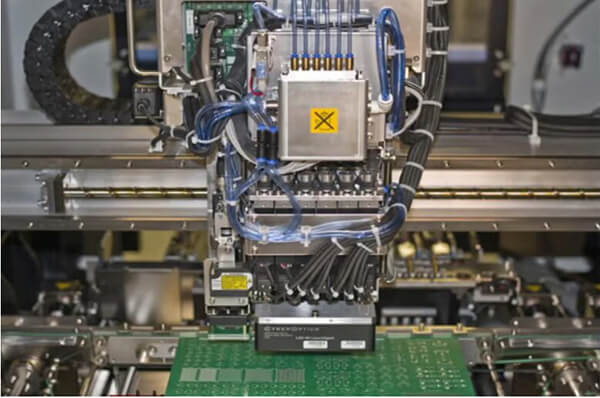

Hybrid SMT and Through Hole Placement Machine

Advanced model for larger/heavier components and larger boards.

6 Nozzles per Gantry (Plus IC head on 3020V)

Can place 6 components simultaneously and center on the fly.

High Accuracy Low Noise Ball Screw Drive

With Linear Encoders.

High Accuracy Laser Align Component Centering

Select centering method based on component type, shape, size and material.

Through Hole Placement

Lead Tip Centering.

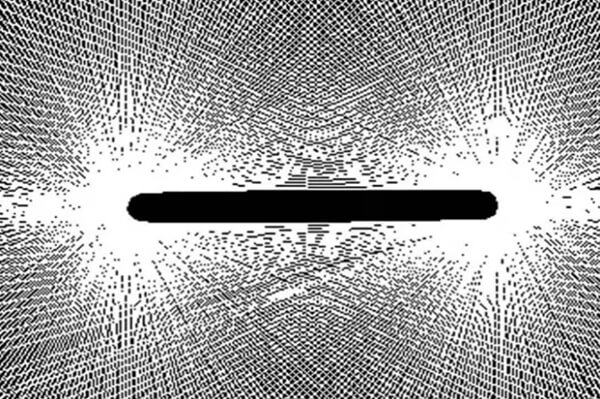

Lead Orientation Detection

The laser sensor is ideal for lead tip detection leading to improved insertion process.

Bowl Feeders (MBF)

MBF (Fixed), MBF-C (Trolley) or MBF-L (for large components).

Radial Feeders (MRF)

MRF-S/M-L, or snap-in MRF-LF

model

JM-50

Substrate size

50x50-410x360mm

Part height

30mm

Part size

0603-50mm

Part placement speed

0.6S/PCS

Part placement accuracy

±0.05 mm(Cpk≧1)

Number of parts mounted

Up to 18 types

power supply

Three-phase AC200V-415V

electricity

1.8kVA

air pressure

0.5±0.05MPa

air consumption

81L/min ANR

External dimensions (W×D×H)

1454×1505×1450mm

weight

1,300kg

Options

Rear side operation unit

●

950mm conveyor height (SMEMA)

●

3D Vision centering system

●

Lead correction jig

●

Feeder trolley

●

Keyboard

●

Automatic conveyor width adjustment

●

External signal tower

●

Super foot

●

Feeder capacity*¹

| Bankd | Max,SMT tape | Radial feeder | Axial feeder | Stacked stick | General purpose | Tray holder | TRSSNK | ||||

| feeders (8mm) | MRF-S | MRF-SN | MRF-L | MAF-S | MAF-L | feeder | bulk feeder MVF | Full | Half | Number of trays | |

| 18mm pitch | 56 | 18 | 18 | 14 | 14 | 10 | 10 | 5 | 1 | 2 | 40 |

| 12mm pitch | Not applicable | 16 | 18 | 12 | 16 | 12 | 12 | 6 | 1 | 2 | 40 |

*1 Max quantity of feeders for given type.

*2 Head height may be restricted depending on feeder location.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky