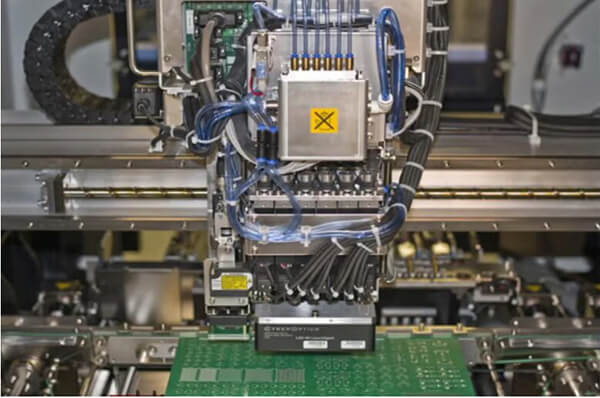

JUKI JM-20 Automatic Insertion Machine

- Improve Quality and Save Labor with Automation

The JUKI JM-20 Insertion Machine automates manual insertion, providing better quality and saving labor costs. By using this machine, you can enhance efficiency and reduce human errors.

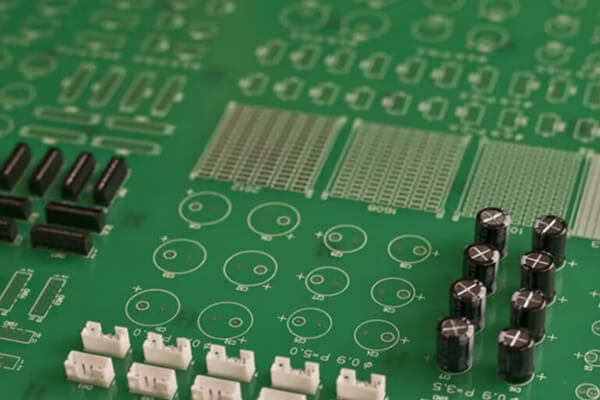

- Perfect for Larger Components and Boards

The JUKI JM-20 is designed for larger and heavier components, as well as bigger boards. Its advanced features ensure precise placement, making it ideal for industries like automotive and aerospace.

- Versatile Multitask Platform

The JUKI JM-20 Insertion Machine handles both Surface Mount Technology (SMT) and Through Hole Technology (THT) placements. This flexibility helps streamline your assembly process and saves floor space.

Key Features

JUKI JM-20 Insertion Machine: Key Features for Optimal PCB Assembly

Exceptional Flexibility

- Component Size: Handles components up to 50 mm square.

- Component Height: Supports up to 55 mm (including lead legs).

- Board Size: Accommodates boards up to 800 mm x 560 mm (X direction requires 2 times clamping).

- PCB Compatibility: Ideal for L/XL size PCBs.

Advanced Slide Insertion (Software Option)

- Precision: Helps insert THT components near high-density areas.

- Component Stability: Prevents component leaning and crashes by nozzles.

- Ideal for Taller Components: Ensures secure placement without clinching lead legs.

Customizable Bulk Feeder

- Efficiency: Supports simple/small connectors supplied in bulk packages.

- Compact Design: Slimmer than traditional bowl feeders.

- Increased Capacity: Allows the machine to run with more feeders simultaneously.

Versatile Nozzle Design

- Wide Range: Over 300 nozzle types available.

- Specialty Handling: Includes vacuum, gripper, axial, and chuck nozzles.

- Adaptability: Manages any odd-shaped components with ease.

Hybrid SMT and Through Hole Placement Machine

Advanced model for larger/heavier components and larger boards.

6 Nozzles per Gantry (Plus IC head on 3020V)

Can place 6 components simultaneously and center on the fly.

High Accuracy Low Noise Ball Screw Drive

With Linear Encoders.

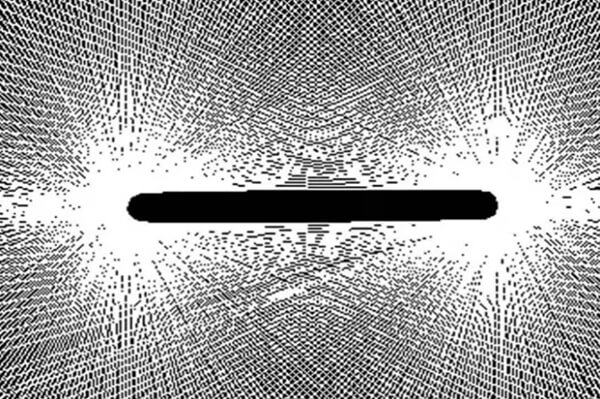

High Accuracy Laser Align Component Centering

Select centering method based on component type, shape, size and material.

Through Hole Placement

Lead Tip Centering.

Lead Orientation Detection

The laser sensor is ideal for lead tip detection leading to improved insertion process.

Bowl Feeders (MBF)

MBF (Fixed), MBF-C (Trolley) or MBF-L (for large components).

Radial Feeders (MRF)

MRF-S/M-L, or snap-in MRF-LF

| Item | JM-20 | |

| Model | L size PCB | XL size PCB |

| Board Size | ||

| Single clamping | 410 x 360 mm | 410 x 560 mm |

| Double clamping | 800 x 360 mm | 800 x 560 mm |

| PCB weight | Max. 4 kg | |

| Component height | Max. 50 mm | |

| Component size | ||

| Laser recognition | 0603~□50 mm | |

| Vision recognition | □3 mm 50 x 48 mm or 1,005 x 24 mm | |

| Placement Speed | 15,500 CPH | |

| Insertion speed (Insertion components) | ||

| Vacuum nozzle | 0.8 sec/part | |

| Gripper nozzle | 1.3 sec/part | |

| Placement accuracy (SMT) | ||

| Laser recognition | ±0.05 mm (3o) | |

| Vision recognition | ±0.04 mm | |

| Power supply | 200 to 415V AC 3-phase | |

| Apparent power | 2.0kVA | |

| Circuit breaker | Standard | |

| Operation air pressure | 0.5±0.06MPa | |

| Air consumption (standard) | 50L/min | |

| Conveyor height | 900 mm ±20 mm | |

| Machine dimension (WxDxH) | 1,500 x 1,657 x 1,550 mm | 1,500 x 1,892 x 1,550 mm |

| Mass (appoximately) | 1,760 kg | 1,985 kg |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky