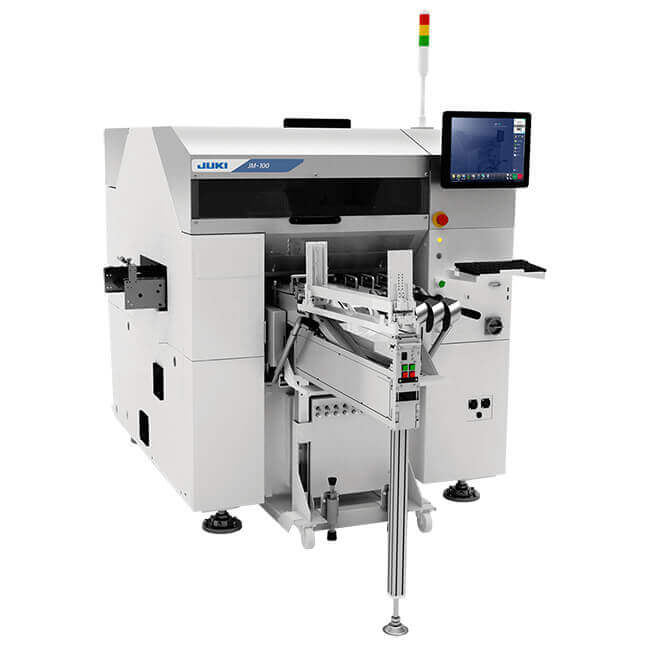

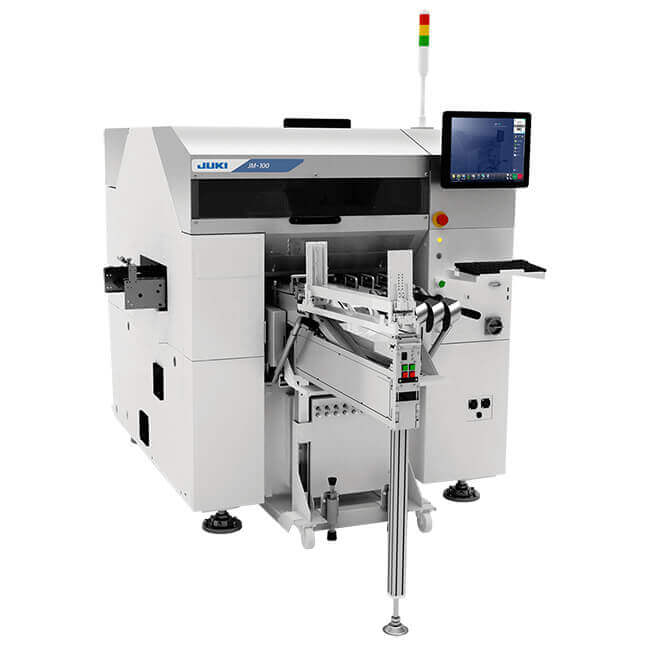

JUKI JM-100 Automatic Insertion Machine

The new JM-100 utilizes Juki’s advanced TAKUMI placement head. This head automatically adjusts it’s height to provide the optimal speed and component handling at the same time. It can pick with up to 8 nozzles at the same time, as compared to the JM-10’s 6 nozzles. The result of these improvements is up to 38% faster insertion time. The TAKUMI head also supports larger and taller components than the previous design.

New options increase the JM-100’s flexibility and capability even further. A clinching unit provides active clinching for a variety of lead sizes and patterns. A new 3D image recognition sensor provides fast and accurate centering of even complicated lead patterns and shapes.

The JM-100 is supported in Juki’s JaNets line control software, along with all other current pick and place models. This makes it easy to program the entire line from one software package.

As a leading company in post-process automation, JUKI is working to develop more automated manual insertion processes for customers. We will continue to offer equipment based on ‘JUKI Smart Solutions‘ to increase productivity, automation, labor saving, and efficiencies of the entire packaging factory, and support our customers.

Feature

Equipped with new “Takumi-Head”. Higher speed and wider component range

Vacuum nozzle insertion time is reduced from 0.8 sec to 0.6 sec (25% faster). Gripper nozzle insertion time is reduced from 1.3 seconds to 0.8 seconds (38% faster). Overall best tact time in class.

In addition, the maximum part size and height that can be handled have also been greatly expanded.

New Clinch Unit to Improve Production Efficiency and Quality

The new active clinch unit option provides greater production flexibility for cases where components have a risk of bouncing out of the PCB. Different clinching patterns are possible including inner bend, outer bend, and N shape bend.

3D Image Recognition Option for High-precision Insertion of a Wide-range of Parts

The 3D recognition option uses a phase-shifting technique to measure the entire component quickly and accurately, including the lead tip. This sensor works well even for low reflectivity components and ones with a wide height range.

Wide variety of nozzles and feeders

Many different feeder types are available for taped, tube, bulk, and tray components. Many standard and custom nozzles make it possible to pick a variety of odd-form components.

JaNets Line Control Software

Juki’s JaNets line control software is compatible with the JM-100. This makes it easier for programmers to prepare files for both the SMT and odd-form machines at the same time.

| JUKI JM-100 Automatic Insertion Machine | ||||

| Standard specification | Clinch specification | |||

| (Lsize PWB) | (Lsize PWB) | |||

| With using Clinch unit | Without using Clinch unit | |||

| Board Size | 1 time clamping | 50㎜×50㎜~410㎜×360㎜ | 80㎜×100㎜~410㎜×360㎜ | 80㎜×50㎜~410㎜×360㎜ |

| 2 times clamping | 50㎜×50㎜~800㎜×360㎜ | 80㎜×100㎜~800㎜×360㎜ | 80㎜×100㎜~800㎜×360㎜ | |

| PCB Weight | max.4kg | |||

| Component Height | max.30㎜ | |||

| Component Size | Laser recognition | 0603~□50mm | ||

| Vision recognition | □3mm~□50mm | |||

| Insertion Speed | Vacuum | 0.6 sec/part*1*3*4 | ||

| (Insertion components) | grip | 0.8 sec/part*2*3*4 | ||

| Placement Accuracy | Laser recognition | ±0.05mm(3σ) | ||

| (SMT) | Vision recognition | ±0.04mm | ||

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky