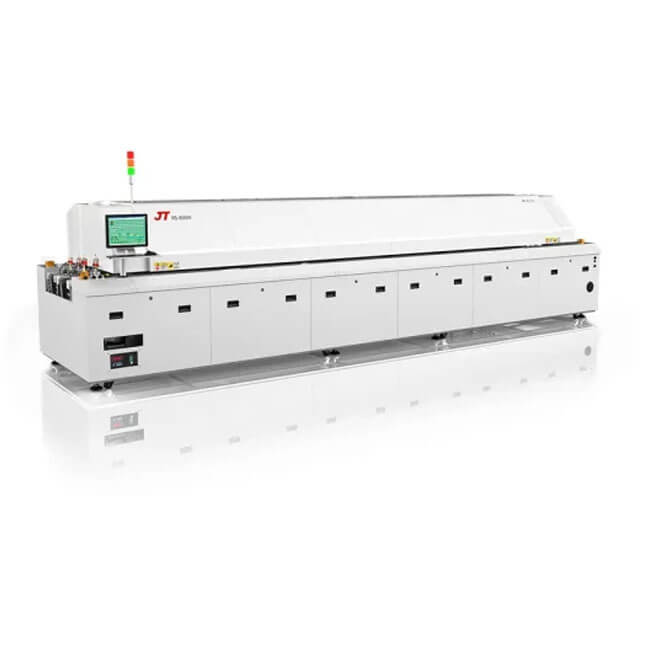

JT RS-800III-N Lead-free nitrogen reflow soldering machine

RS Series Lead Free Hot Air Reflow Oven

● Independent Air Velocity Controlling by section can achieve flexibleprocessing adjustment, therefore dealing with various & complicated Lead Free Processing easily;

● New Cooling Configuration to make the filteredor reclaimed air back to oven chamber, it reduced the thermal loss as well as get better flux reclamation;

● Longer maintenanceperiod for oven chamber;

●New Air Management System withsignificant energy save, lower electric power consumption & lower carbon;

● The chambers with multi-layers and thicker thermalinsulation to attain the lower temp. of oven surface.

● 95 % Materials of Reflow Oven can be recycled.

Description

|

|

as JT provided : S = Standard, O = Option |

|

MODEL |

RS-800III / RS-800III-N |

|

GENERAL |

|

|

Outside Dimension(L*W*H) |

5520 x 1430x 1530mm |

|

Weight |

Approx. 2400KG / 2500KG |

|

Number Of Heating Zones |

Up 8 / Bottom 8 |

|

Length Of Heating Zones |

3110mm |

|

Number Of Cooling Zones |

Up 3 / Bottom 3 ( Cool Air Conversion) |

|

Exhaust Volume |

10 M3 / min x 2 (Exhausts) |

|

Control System |

|

|

Electric Supply Required |

3 phase, 380V 50/60Hz (Optional: 3 phase, 220V 50/60Hz ) |

|

Electric Power Required |

64KW / 67KW |

|

Power For Warm Up |

30KW / 32KW |

|

Power Consumption |

9KW / 10KW |

|

Warming Time |

约 Approx. 25 minute |

|

Temp. Setting Range |

Room Temp. — 300℃ |

|

Temperature Control Method |

PID Close Loop Control + SSR Driving |

|

Temperature Control Precision |

± 1.0℃ |

|

Temperature Deviation on PCB |

± 1.5℃ (by JT Board Test Standard) |

|

Commutated Element |

Aluminium Alloy Plate |

|

Data Storage |

Various prameters and status are storable |

|

Abnormal Alarm |

Abnormal Temperature (Extra-high / Extra-low Temp.) |

|

Board Dropped Alarm |

Tower Light: Yellow–Warming; Green-Normal; Red-Abnormal |

|

Conveyor System |

|

|

Rail Structure |

Subsection Integrated Type (Option : Subsection Separate Control) |

|

Max.Width Of PCB |

400mm ( Option: 460mm ) |

|

Range Of Rail Width/Adjustment |

50–400mm/ Motorized |

|

Components Clearance |

PCB Top 30 / Bottom 25mm |

|

Converyor Direction |

L→R ( Option: R→L) |

|

Fixed Rail Side |

Front Rail Fixed (Option:Rear Rail Fixed) |

|

PCB Transmission Agent |

Air-Reflow = Chain + Mesh , |

|

(N2-Reflow = Chain only and Mesh optional) |

|

|

Converyor Height |

900±20mm |

|

Converyor Speed Range |

300~2000mm/min |

|

Lubrication Auto-Afflux |

Standard |

|

Cooling System |

|

|

Cooling Method |

Standard:Forced-Air Type |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky