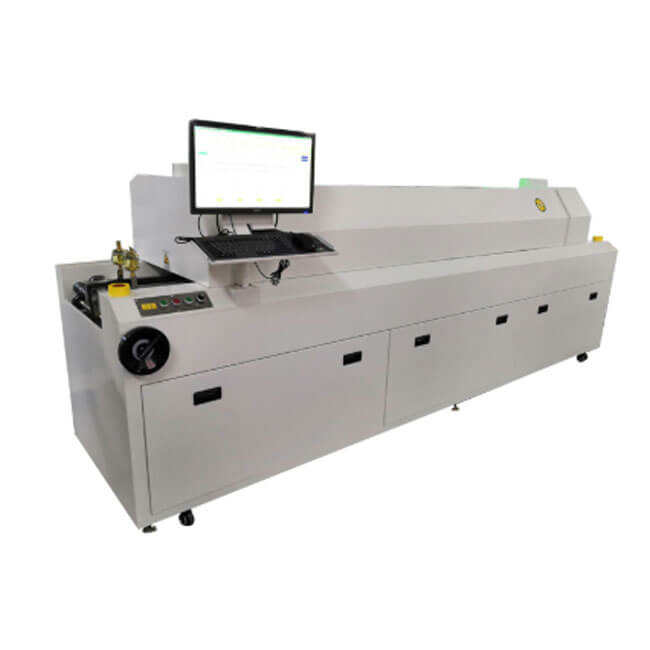

China 600S Reflow Soldering Machine

Using liquid crystal computer + Intelligent Control System, high temperature control accuracy ± 1 °C (if the computer accidentally died, can realize off-line work, does not affect production) , to ensure stable and reliable control system;

Windows XP and Windows 7 operating interface, powerful, easy to operate, and with a key restore system;

The upper furnace body is opened with a cylinder jacking machine to ensure safety and reliability

Equipped with net belt tension device, smooth transportation, no jitter, no distortion, to ensure smooth PCB transportation;

Transmission Mechanism of synchronous Guide Rail (can connect with automatic mounter on-line) to ensure accurate width adjustment of guide rail, Long Service Life and anti-button curve

Manual Control Lubrication System, through manual to set the amount of lubrication transmission chain;

All heating areas are PID controlled by computer (can be divided into separate temperature areas opened separately. Can Be divided to reduce the starting power, heating time 10-15 minutes) ;

The network/chain transmission is controlled by computer in full closed loop, which can meet the needs of different kinds of PCB production

Has the breakdown sound and light alarm function (uses the LED lamp) ;

Windows XP and Windows 7 operating interface, powerful, easy to operate, and with a key restore system;

The upper furnace body is opened with a cylinder jacking machine to ensure safety and reliability

Equipped with net belt tension device, smooth transportation, no jitter, no distortion, to ensure smooth PCB transportation;

Transmission Mechanism of synchronous Guide Rail (can connect with automatic mounter on-line) to ensure accurate width adjustment of guide rail, Long Service Life and anti-button curve

Manual Control Lubrication System, through manual to set the amount of lubrication transmission chain;

All heating areas are PID controlled by computer (can be divided into separate temperature areas opened separately. Can Be divided to reduce the starting power, heating time 10-15 minutes) ;

The network/chain transmission is controlled by computer in full closed loop, which can meet the needs of different kinds of PCB production

Has the breakdown sound and light alarm function (uses the LED lamp) ;

Specification

Suitable type of solder paste

Lead-free solder, common solder, red glue

Maximum size of machined substrate (MM)

MAX 400(mm)

Fuselage size L*W*H(MM)

3600*1050*1450mm

Body weight

800KG

Temperature composition

Upper 6 temperature zone, lower 6 temperature zone, 12 temperature control, axial flow fan

Temperature control mode

Each temperature zone is independently controlled by temperature module PID + pulse + SSR

Temperature control accuracy

±1℃

Temperature control range

Room temperature ~ 350℃

Warming-up time (Chiller start-up)

About 15 minutes

Wind mode

Using the world’s leading hot air circulation technology, the rational use of hot air circulation through turbocharging makes the hot air stable; high thermal efficiency circulation utilization rate, that is, energy saving and stable, PCB mass through, the temperature curve on each PCB is always the same as that on only one board. The repeated precision of heating is very high, which is very suitable for the small process space in lead-free process. (improved by imported furnace technology)

Internal structure

The double outlet of the turbine is used to increase the pressure of the wind speed so that the wind speed is stable and the temperature is stable

Bandwidth of transmission network

400mm

Mode of transmission

/Mesh Belt Transmission

Direction of delivery

Left → right, right → left (optional)

Level of transmission chain

900mm±20

Transport speed

0~2200mm/min

Cooling Zone

AC220V straight shaft fan mode

Cooling Mode

1 Separate Cooling Zone

Power Supply

THREE-PHASE FIVE-WIRE 380V

Total Power

25KW

Starting power/no-load power

20KW/0.5KW

No-load constant temperature power

Approx. 5KW

Cooling Zone

AC220V straight shaft fan mode

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky