Axxon Mycronic MYS10iL Atmospheric Argon plasma cleaning machine

The Axxon Mycronic MYS10iL plasma system enables atmospheric plasma treatment for large size products that previously could only be that previously could only be cleaned within vacuum plasma chambers.

Electronics assembly and semiconductor markets are rapidly changing with ever increasing reliability and throughput requirements. The Axxon Mycronic MYS series is designed to increase yield and throughput by eliminating the time variables associated with vacuum plasma while still being safe to operate on your sensitive electronics.

Product Features

- Atmospheric pressure argon plasma system

- Inline plasma with 100mm beam width for batch mode production. Compared with traditional

plasma treatment methods, the efficiency has been increased by 2-5X, and cost reduced by

more than 30%

- Safe and friendly. Free of sparks, streamers, particles, UV and heat, ESD safe for sensitive components

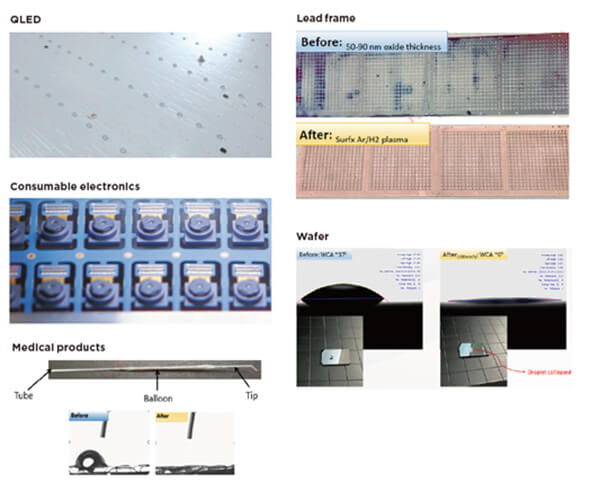

- Multiprocessing plasma innovative technology: O2 process removes organic pollutants, H2 process

removes metal oxides and activates the surface of the product

- No particle contamination nor liquid pollutants

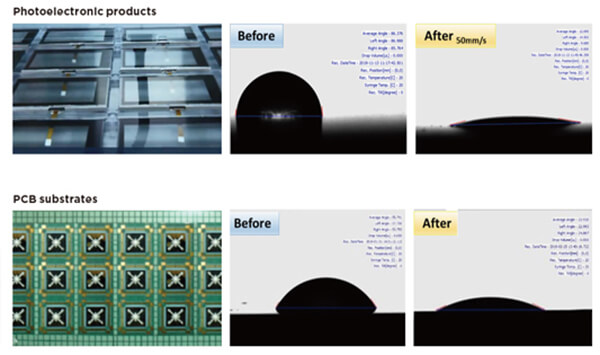

MYS10iL is an inline plasma treatment system for various industries: semiconductor, consumable electronics,

SMT, photoelectronic and medical industry.

Specifications

|

Specification |

MYS10iL |

|

Power supply |

AC 200~240V, 4.5 kW, 20A, 50/60 Hz |

|

Air supply |

90psi(6bar) |

|

Dimension |

1000x1500x1550mm |

|

Weight |

885kg |

|

Standard compliance |

CE |

|

Working range |

|

|

Working area of plasma (WxD) |

550~760mm |

|

Contact angle after plasma cleaning (WCA) |

WCA<10° (Wafer) WCA<20° (Plastic) |

|

Plasma cleaning method |

O2 process to remove organic pollutants H2 process to remove metal-oxides |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky