ASM SIPLACE X4i S Pick and place machine

The benchmark in high-volume production

Absolute precision and maximum performance have made the SIPLACE X S the placement platform of choice for demanding high-volume production applications such as network infrastructure (5G), large boards for server and industrial segments. Wherever top speed, lowest dpm rates, non-stop setup changeovers, fast new product introductions and the high-speed placement of the latest generations of super-small components (0201 metric) are needed – the SIPLACE X S delivers.

Highlights of the ASM SIPLACE X S:

SIPLACE Placement Head CP20 for high-speed and placement of components as small as 0201 (metric) with maximum precision

CP20 Head – for maximum accuracy and speed:

- For components ranging from 0.12 × 0.12 mm (L × W) to 8.2 mm × 8.2 mm and 4 mm (L × W × H)

- Speed: Up to 48,000 cph

- Accuracy: Up to ±25 μm @ 3 σ

- Placement force: 0.5 N to 4.5 N

- Perfect for the fast assembly of standard components at the head of the SMT line

SIPLACE Placement Head CPP – the only head that automatically changes modes on demand (C&P, P&P, Mixed Mode)

CPP Head – for maximum flexibility:

- Switches as needed between pick-and-place, collect-and-place and mixed modes

- For components ranging from 01005 metric to 50 × 40 x 15.5 mm (L × W × H)

- Speed: Up to 25,500 cph

- Accuracy: Up to ±34 μm @ 3 σ

- For perfectly balanced line operation during quick product changeovers with no time-consuming configuration and head changes

SIPLACE Placement Head TWIN – the head for special tasks

Twin Head – for maximum force:

- Places components ranging from 0201 metric to 200 × 110 × 25 mm (L×W×H)

- Speed: Up to 5,500 cph

- Accuracy: Up to ±22 μm @ 3 σ

- Placement force: 1.0 N to 30 N

- Snap-in detection and 3D measurement in real time

- Perfectly suited for automated end-of-line placement of large and heavy components such as connectors, specialty components, and odd shapes

Digital SIPLACE vision system for maximum process stability

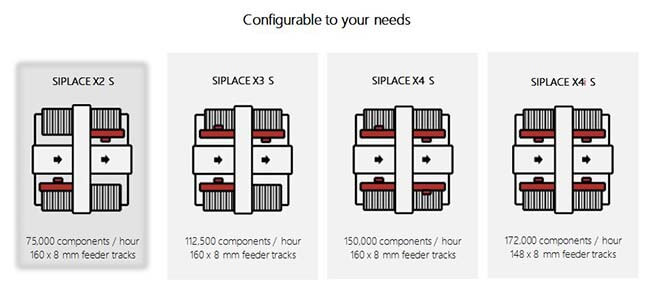

Available with two, three and four gantries and smart conveyor options for optimized line configurations

Modular gantries to meet any production challenges

SIPLACE Smart Pin Support for automatic placement of PCB support pins

| Technical | SIPLACE X2 S | SIPLACE X3 S | SIPLACE X4 S | SIPLACE X4i S |

| Placement speed** | 75,000 cph | 112,500 cph | 150,000 cph | 172,000 cph |

| Placement speed (IPC) | 65,000 cph | 97,050 cph | 130,000 cph | 146,000 cph |

| Feeder capacity | 160 × 8 mm slots | 148 × 8 mm slots | ||

| Component spectrum | 0201 (metric) to 200 mm × 125 mm × 25 mm | |||

| Board size | 50 mm × 50 mm to 850 mm × 685 mm | |||

| Machine dimensions (L x W x H) | 1.9 m × 2.6 m × 1.6 m | |||

| Placement heads | SpeedStar (CP20), MultiStar (CPP), TwinStar (TH) | |||

| Placement accuracy | 22 µm @ 3 σ (with TwinStar) | |||

| Conveyors | Single-track conveyor, flexible dual-track conveyor | |||

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky