ASM SIPLACE CA Pick and place machine

Chip assembly and SMT placement in a single machine

Integrate high-growth technologies of the future such as flip chips and die attach into your SMT production with the ASM SIPLACE CA Pick and place machine, the world’s first platform that lets you flexibly combine the placement of bare dies directly from the wafer with classic feeder-based SMT placement.

Your competitive advantage: New, future-proof applications can be implemented on a single SMT line without any additional special processes. It is the ideal machine for “Advanced Packaging” applications. Another benefit: For all other jobs, the SIPLACE CA operates as a powerful “normal” SMT placement machine.

- The ASM SIPLACE CA has a throughput of 46000 cph (flip chip), 30000 cph (die attach), and 126500 cph (SMD).

- ASM SIPLACE CA supports die sizes of 0.5-15.0 mm (flip chip), 0.8-15.0 mm (die attach) & 0.11-15.0 mm (SMD), and a die thickness of more than 50 μm (silicon).

- ASM SIPLACE CA supports various packages like RF-MCM, FCIP, FC-MLF, FC-CSP, etc.

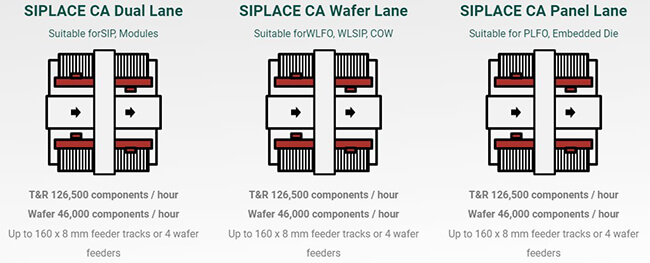

- The SIPLACE CA supports wafer sizes from 4 to 12 inches and has a 12/8-inch (6 and 4-inch optional) wafer stretcher to stretch wafers from 2 to 8 mm. It supports flexible dual, single-lane, wafer-lane lane & panel-lane conveyors.

- ASM SIPLACE CA supports substrates like FR4, ceramics, flex, boats, 8/12-inch wafers, etc. of sizes ranging from 50 x 50 mm to 685 x 685 mm (conveyor type dependent) and thickness from 0.3 to 4.5 mm.

- ASM SIPLACE CA can handle hoop rings and supports wafer maps.This horizontal wafer system has multi-die capability and supports automatic wafer exchange.

- The SIPLACE CA has a footprint of 3778 x 2100 x 1835 mm and requires a three-phase AC supply of 400 V.

|

SIPLACE CA |

Panel Level Configuration |

Wafer Level Configuration |

|

|||

|

Application |

Flip Chip |

Die Attach |

Flip Chip |

Die Attach |

SMD |

|

|

Accuracy |

± 12 µm at 3 σ |

± 12 µm at 3 σ |

± 10 µm at 3 σ |

± 10 µm at 3 σ |

± 15 µm at 3 σ |

|

|

Throughput |

CP20M2 |

46 |

30 |

46 |

30 |

126 |

|

(flip chip without dipping) |

CPPM |

41 |

29 |

41 |

29 |

85 |

|

Die / component sizes CP20M2 |

0.5 – 6mm |

0.8 – 6 mm |

0.5 – 6mm |

0.8 – 6 mm |

0201m – 6mm |

|

|

Die / component sizes CPPM |

0.5 – 15mm |

0.8 – 15mm |

0.5 – 15mm |

0.8 – 15mm |

0402m – 15mm |

|

|

Die thickness min. (Silicon) |

50 µm |

50 µm |

50 µm |

50 µm |

n / a |

|

|

Bump size min. 3) |

25 µm |

n / a |

25 µm |

n / a |

n / a |

|

|

Bump pitch min. 3) |

50 µm |

n / a |

50 µm |

n / a |

n / a |

|

|

SIPLACE Wafer System SWS |

Horizontal system, automatic wafer exchange, MCM |

|||||

|

SWS wafer size |

4″ – 12″ |

n / a |

||||

|

Wafer stretcher |

12″ / 8″ |

n / a |

||||

|

Wafer stretch range |

2mm – 8 mm |

n / a |

||||

|

Die eject system |

Programmable eject speed |

|||||

|

Linear Dipping Unit LDU |

Free programmable flux application speed |

|||||

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky