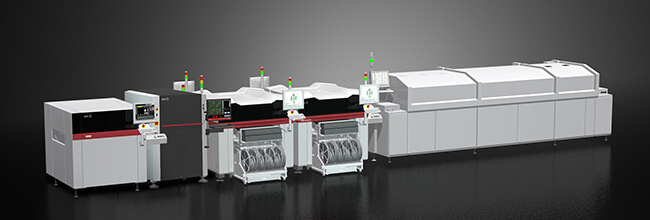

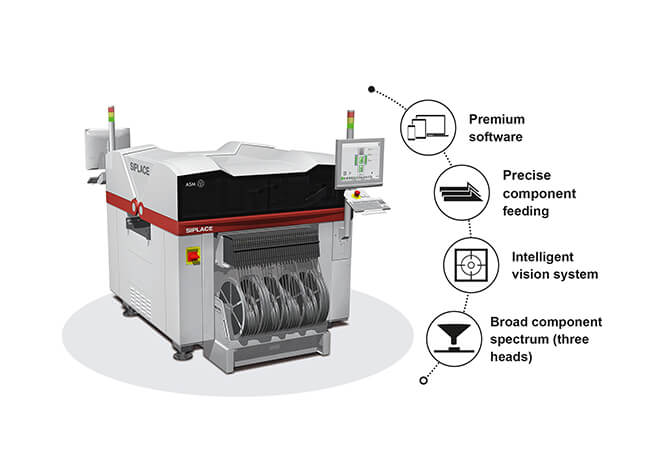

ASM E by SIPLACE Pick and place machine

The E by Siplace pick and place machine utilizes advanced technology to achieve precise and reliable component placement. It offers high-speed and high-accuracy placement, ensuring efficient production processes and optimal assembly quality. With its innovative vision system and intelligent software, the E by Siplace machine delivers exceptional performance and maximizes productivity. Designed to accommodate a wide range of components, the E by Siplace pick and place machine offers exceptional flexibility in component handling. It supports various package types, including resistors, capacitors, ICs, connectors, and more. This versatility enables manufacturers to adapt to different assembly requirements and component specifications, ensuring a seamless production process. The E by Siplace machine features a user-friendly interface, simplifying machine setup, job management, and real-time monitoring. The intuitive interface enhances operator efficiency and reduces setup time, streamlining the production workflow. With its user-friendly design, the E by Siplace pick and place machine enables seamless integration into manufacturing processes.

placement Heads

The SIPLACE pIacement heads are famous for their precision, speed and fexibility:

- ReIiabIe, individuaIIy programmabIe pIacement force controI

- Automatic adjustment to board warpage

- Combined coIIect-and-pIace and pick-and-pIace units turn a single-gantry E into the frst real all-rounder

Feeders

Each component in exactIy the same position every time:

- Smartfeeder E precision drives

- CIosed-IoopcontroI system

Smartfeeder E:

- CaIibrates itseIf

- Features exceptionaI robustness

- Hot-swappabIe

- Requires very IittIe maintenance

C0mp0nent Tables

The new E by SIPLACE component tabIes:

- Support fast setup and tear-down of feeder moduIes, even during the pIacement process

- work with Smartfeeder E and more feeding options

- offer a totaI of 120 8 mm feeder sIots with two component tabIes attached to the E by SIPLACE

Drives

Maximum head speed and precision:

- State-of-the-art Iinear motors

- Exact positioning via high-resoIutionscaIing

- Modern sensors

- Decades of experience in controI software

The stiff chassis and precise Iinear drives deIiver quaIity by design and for a Iong time to come.

Digital visi0n system

E by SIPLACE features high-resoIution SIPLACE digitaI vision system:

- Each component is individuaIIy captured and inspected

- Individual lighting confgurations capture more details than shapes

- wizards for extremIy fast and reIiabIe teaching

- Easy teaching with modern image recognition aIgorithms

- AIways operates at the highest speed, even for the smaIIest components

| placement head | Cp14 | Cp12 | Cp12lpp | Cp6lpp | TH |

| E-Component range | 01005 - | 01005 - | 01005 - | 0201 - | 0201 - |

| 6 x 6 mm | 18.7 x 18.7 mm | 45 x 98 mm | 45 x 98 mm | 200 x 110 mm | |

| E-Component height | 4 mm | 7.5 mm | 19 mm | 19 mm | 25 mm |

| E-Accuracy (3σ) | 41 μm | 41 μm | 37.5 μm | 37.5 μm | 22 μm |

| E-speed | 45,300 cph | 24,300 cph | 24,200 cph | 13,700 cph | 5,200 cph |

| placement machine | SIpLACE E | ||||

| Heads | CP14, CP12, CP12/PP, CP6/PP, TH | ||||

| PCB size (LxW)* | 1,200 x 460 mm | ||||

| PCB thickness | 0.3 - 4.5 mm | ||||

| Feeder capacitY | 120 x 8 mm | ||||

| Power suppIY | 3 x 200/208/220/230/380/400/415 VAC ± 10%, 50/60 Hz, 1.8 KW | ||||

| Compressed air | 5.0 bar (0.5 MPa) - 10.0 bar (1.0 MPa) | ||||

| Air consumption | 90 NL/Min | 90 NL/Min | 140 NL/Min | 140 NL/Min | 185 NL/Min |

| Dimensions (LxW)** | 1,460 mm x 1,730 mm | ||||

| Weight*** | 1,850 kg | ||||

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky