YAMAHA YRi-V 3D AOI Machine

Super high-speed 3D inspections

56.8cm²/sec (under optimum conditions)

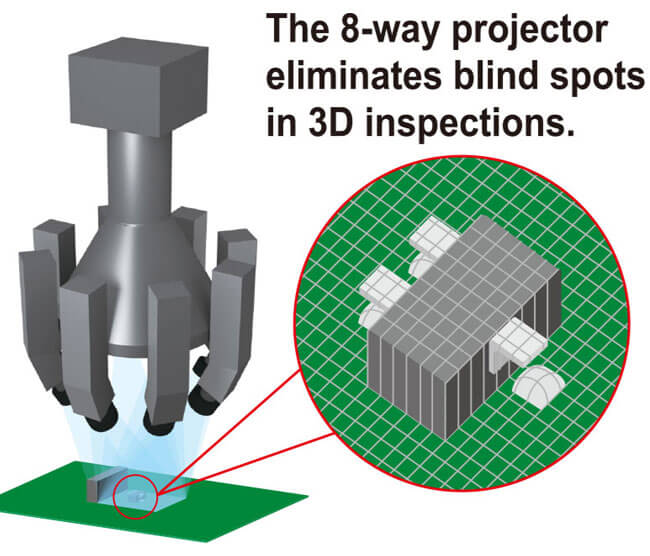

Super high-accuracy 3D inspections

8-way projector

4-way oblique imaging inspections

20Megapixels 4-angle camera

Device inspections

Super high-resolution 5μm/coaxial lighting

Function and Feature

For customers who are seeking a super high-speed, high-accuracy and high-spec 3D inspection

It supports high-accuracy inspection in the device sector by the 5μm lens with the coaxial lighting.

For customers need high-speed inspection for semiconductor products.

Realize high-speed, high-Accuracy inspections

Feature

Super high-speed and high-accuracy inspectionsNew type of inspection head

The newly developed high-performance inspection head significantly improve the inspection performance of the 2D inspections, 3D inspections, and 4-angle cameras. The inspection performance can be applied to all SMT sectors

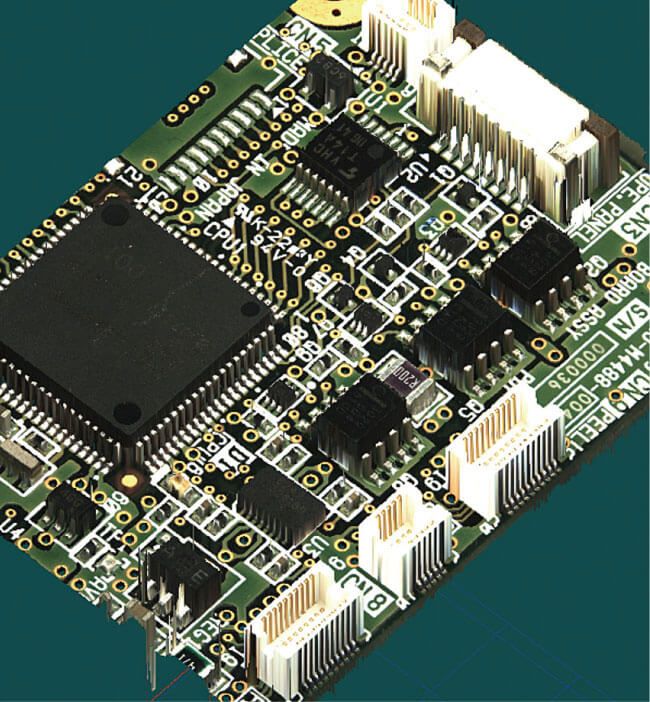

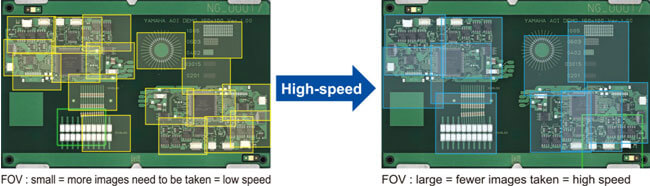

Super high-speed inspections

Yamaha’s proprietary high-rigidity frame realizes high-accuracy and super high-speed inspections. The inspection speed is 1.6 to 2.0 times as before, which supports inspections in mass-production.

8-way projector / 4-way projector(select)

The 8-way projector added to the lineup has enabled inspecting 0201mm components mounted adjacently. The projector reduces the number of blind spots for large components, realizing high-accuracy 3D inspections. The increased 3D measurement range enables 3D inspections of components with heights of up to 25mm.

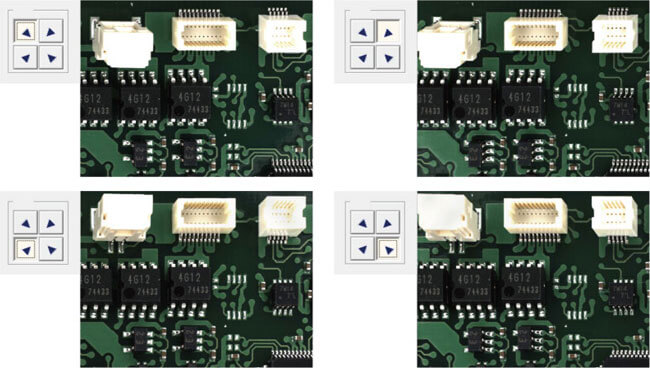

20Megapixels 4-angle cameras

20Megapixels high-resolution cameras were adopted. Clear images enable accurate secondary judgment. The higher picture quality improves the accuracy of automatic inspections based on oblique images.

Latest software solution using AI

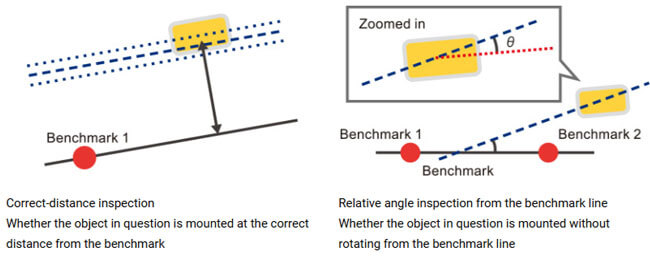

Measuring LED position

It can measure the LED position, which requires accurate position measuring from the benchmark. Measuring tests made possible thanks to the highly robust frame.

Mobile Judgement and QA option

Inferior images are sent to the operator’s mobile unit via a wireless LAN, which makes it possible to judge pass or fail remotely. The system allows line operators to also make decisions, contributing to labor savings.

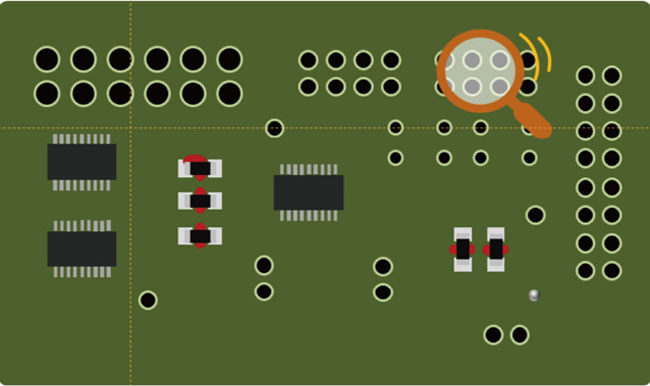

Automatic inspection data creation

The system can directly convert all types of data (e.g., CAD, CAM, and mounter data) into inspection data and automatically creates PCB images from Gerber data. The system detects through holes on DIP PCBs automatically and can create inspection data automatically.

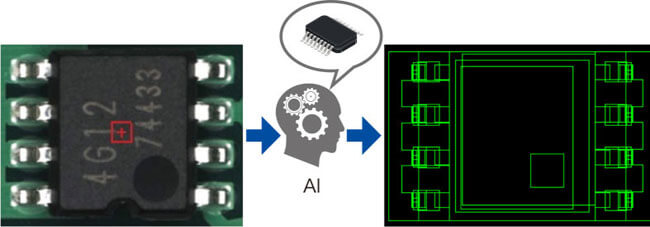

Automatic component library matching [AI function]

AI automatically identifies the component types based on images taken by the camera and applies the optimum component library automatically, contributing to simplifying the inspection data creation.

Inspection variations for semiconductor industry

Achieves high-speed and high-accuracy inspections with a new camera model

Super-high resolution / super-high speed inspections [25Megapixel camera]

Realizes a wide field of view even with a resolution of 5μm, thanks to the new 25Megapixel camera. Achieves even faster inspections for semiconductor industry.

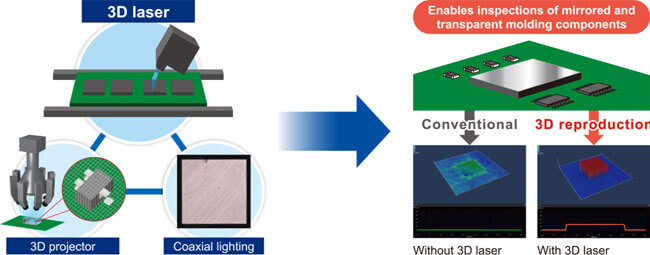

Inspection for wafer and transparent molding components [3D laser]

With a 3D laser and coaxial lighting, the surface of mirrored components and transparent molding components is accurately captured, improving 3D reproductivity. Enables inspections of components that were previously difficult to inspect.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky