TAKAYA APT-2600FD-SL Flying Probe Tester

Your Gateway to Quality

The APT-2600FD series is a high-performance flying probe test system with 4 heads and 6 probes on the top, and 2 heads and 4 probes on the bottom, enabling simultaneous double-sided contact.

Its advanced measurement system and versatile testing capabilities significantly improve test coverage and detect manufacturing defects in assembled PCBs.

Offering various models for large PCB and automated testing, the APT-2600FD series reduces testing costs from prototyping to mass production while enhancing assembly quality.

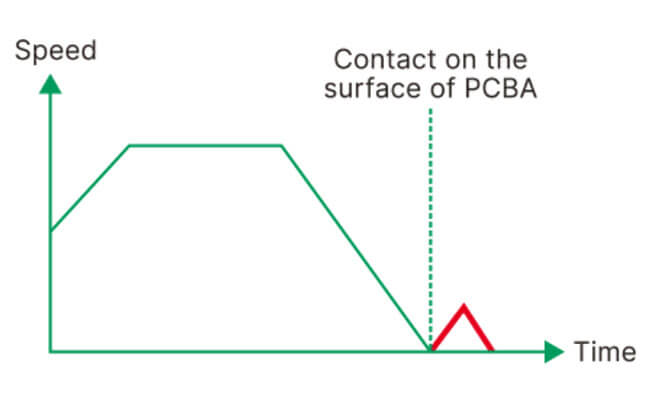

Zero-Impact Probe Control

Gentle on Boards with New Control Technology, Reducing Risk of Component Damage

To minimize impact, the system reduces probe speed to zero just before contact, using only spring pressure. This greatly reduces stress on contact points and lowers the risk of board damage, ensuring safe, accurate testing even for delicate PCBs.

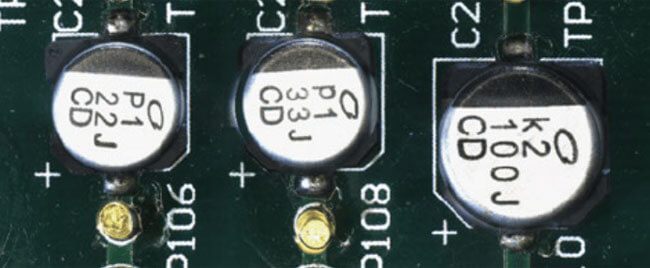

High-Resolution Vision System with Multi-Function

Clear Imaging of Tall Components, Adding 3D Display to High-Precision AOI

With a high-resolution camera and liquid lens technology, the system provides a wide depth of field, capturing clear images regardless of component height, making it easy to read markings on tall components. In addition to high-performance OCR and AOI, the imaging has evolved from 2D to 3D real maps, enabling checking of hard-to-reach areas and net connections between the top and bottom of the PCB.

Remote Camera

Remote Monitoring Capabilities to Optimize Production Lines

Equipped with a standard remote camera for monitoring the inside of the tester, remote monitoring via a browser is possible. This enables labor-saving automation of production lines.

Like a drive recorder, it has a feature that automatically captures the situation when trouble occurs, and a safety feature that checks the internal state before the start of testing and interrupts the test if an abnormality is detected.

This makes it easier to trace and analyze the cause of problems when they occur, improving operational efficiency and minimizing downtime.

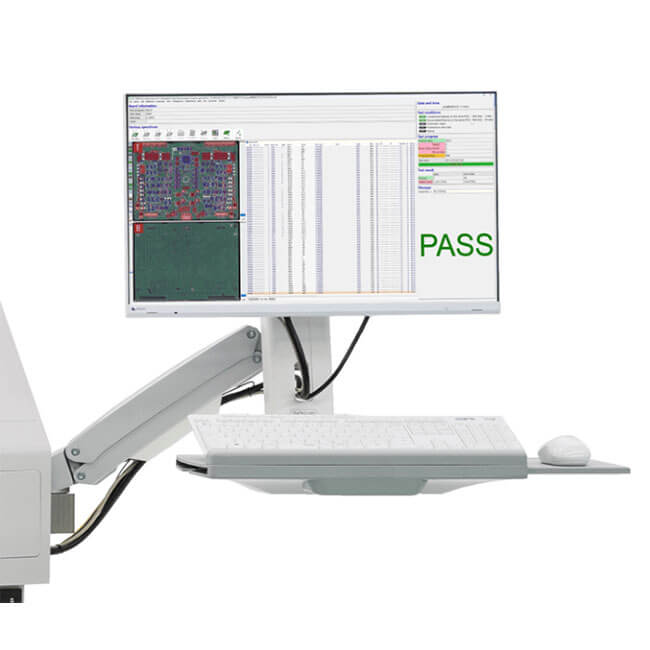

Universal Design

Flexibility and Comfort to Fit Various Work Environments

The monitor arm and operating system are designed with universal design to accommodate the diverse working styles and operating environments of users. The angle and height of the screen can be freely adjusted, making it comfortable to operate in both standing and sitting positions. Additionally, the arrangement can be easily changed to suit the dominant hand, improving work efficiency, and reducing fatigue even during long hours of work. It offers flexibility and comfort that can adapt to various work environments.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky