Stencil Inspection System SVII-K80S

Stencil inspection machine can quickly solve the problem of opening and the cleaning of stencil, and improve the cleaning process; Establish control standards of stencil and improve production management system.

Full Automatic Stencil Inspection System

This is the first and leading full automatic stencil inspection machine in China, which can solve all the problem for making and cleaning the stencil, improve the cleaning process, establish stencil management standard, improve the production management system, automatic inspection instead of manual checking, reduce the labour cost, improve the products quality as well as solve the excess solder, insufficient solder short problem at the very beginning.

Process Improvement

1. Solve the problem in receiving and cleaning the stencils, improve the cleaning process

2. Establish stencil management standard, improve production management system

3. Automatic inspect instead of manual checking, improve products quality

4. Solve the excess solder, insufficient solder short problem at the very beginning.

5. The 01005 component or even more smaller component are widely used in the production now, high precision inspect is needed for future development.

Designed for Precision

High-speed Linear Motor (magnetic suspension transmission) movement and control drive device,applied with DKM adjustable liner motor driving module to ensure the high precision of the liner movement, and avoid the low precision issue occurred due to the corrosion after used the traditional lead screw for a long time.

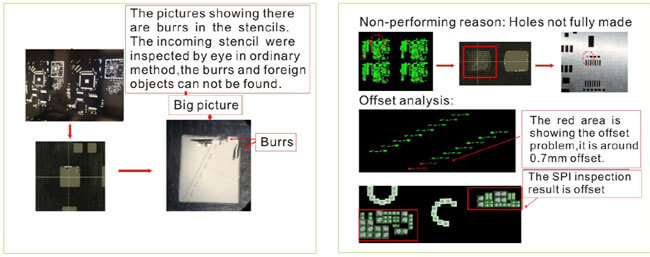

Case Analysis

Features:

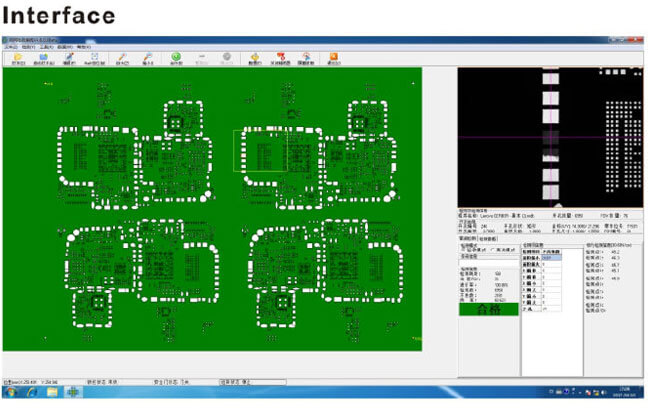

Input GERBER data and modularizing the data structure. The results an be viewed after immediate measuring within 3 min.

Input CAD file, the inspection data can match with SPI immediatedly, then can go back to check.

It combines the different SPC analysis automatically, so it resolved and standardized the design of the stencils, and to guide the application for our clients promptly and easily.

Inspect for apertures area, position, offset, size, foreign objects, burr, hole clogging, miss hole, tension and solder paste all printed data etc. of stencil

The open type of communication protocols can communicate with in-line real time system or machine in the market. All stencil ID number, data and status can be checked at any time.

The fastest speed in the world, it only take 2 min. to inspect a PCB board with 230mm*150mm, including to check the data and SPC analysis.

The world's fastest detection speed, standard PCB230 * 150 measurement speed of 2 minutes, including view data structure SPC analysis

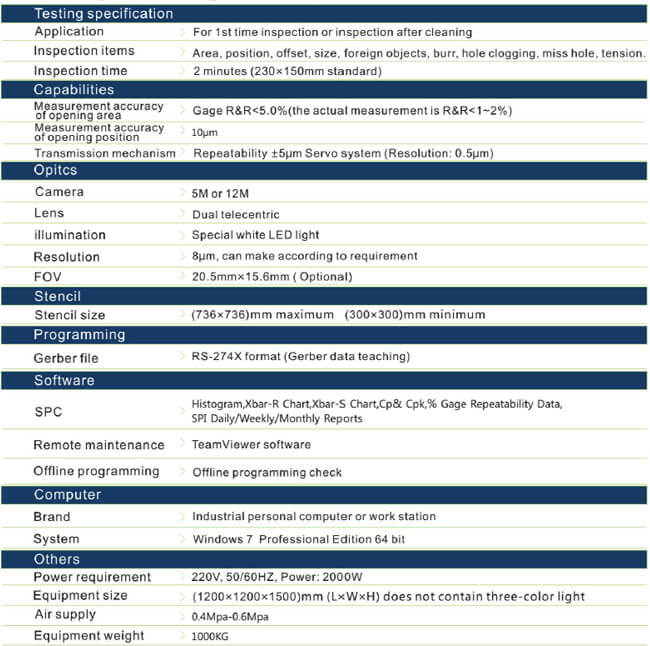

Technical Parameters(SVII-K80S)

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky