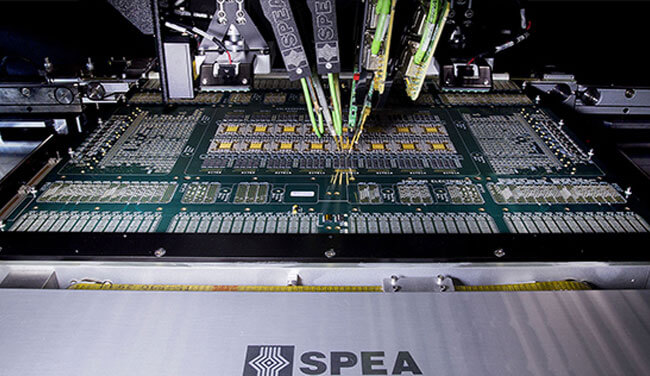

SPEA 4060 S2 Flying Probe Tester

Key features

Dual side probing: full accessibility & parallel test

Large boards testing: 1000 x 610mm (39.4 x 24’’)

20 kg max board weight

Full test coverage

Conveyor / Automatic / Manual board loading

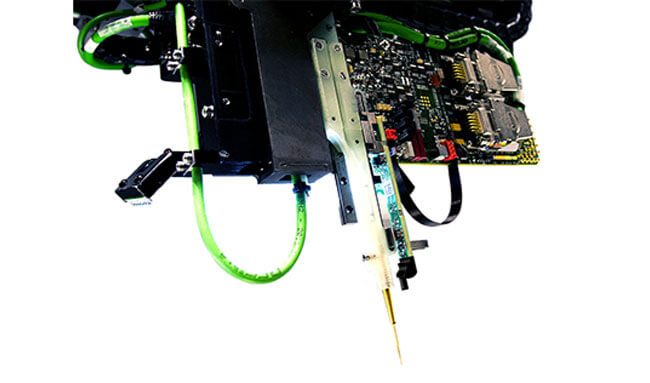

Micro-SMD & flexible circuit probing

Features

Multi-Mode Dual Side Probing

4060 S2 combines the advantages of dual-side flying probing, with the possibility to use additional tools such as fixed probes, planarity supports, mini bed-of-nails fixtures, and more.

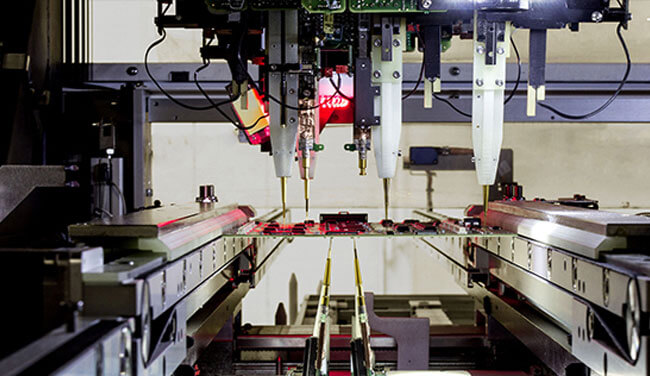

DUAL-SIDE FLYING PROBING

BOTTOM MULTI-PROBE FLYING HEADS

MULTI-MODE PROBING

Test also the biggest ones.

LARGE TEST AREA: The large test area allows 4060 S2 to fit boards with up to 1000 x 610mm (39.4 × 24’’) size

BACKPLANES: 4060 S2 can test backplanes mounting any type of connector.

TALL COMPONENTS: 4060 S2 tests also PCBs with transformers, heat sinks, connectors, front panels, polarized capacitors and other tall components up to 110mm.

Best Measurement Accuracy

Highest measurement performance & accuracy (0.1pF)

Signal integrity

No measurement degradation or interference

Immediate signal acquisition (within hundreds of microseconds)

Fast and accurate probing on the smallest components

ULTRA HIGH-SPEED AXES. Full Linear Motion

ACCURATE MICRO-PAD CONTACTING

ULTRA-FAST SOFT TOUCH TECHNOLOGY

Full accessibility & parallel test

DUAL-SIDE FLYING PROBING: Four top-side and two bottom-side moving heads make 4060 S2 able to perform flying probe test on both sides of the board simultaneously, increasing throughput and test capabilities.

BOTTOM MULTI-PROBE FLYING HEADS: In addition to electrical probes for electrical tests, the two bottom multi-probe flying heads can move high-speed power probes, support rods, hi-res cameras, multi-probes, laser & LED probes and electro scan probes, covering the most comprehensive test needs.

MULTI-MODE PROBING: While using the 4 top-side probes to perform flying probe test, a bottom moving platform can be used for bed-of-nails fixtures, multiple high-current power supplies, digital I/O, high-speed signals. The dynamic planarity supports allow you to reliably test large and thin boards, avoiding PCB vibrations due to probe strokes.

Leonardo OS2

Easy. Fast. Self-programming.

Automatic test program generation in minutes

Automatic test program generation with or without CAD file

– 50% test program generation time with new S2 System Control

Faster & fully automatic Debug & Tuning

Automatic board repair software

Automatic Pick & Place X-Y file import

Built-in Self-Test (BIST) compliant

User-friendly intuitive graphical interface

Control software to monitor, analyze & optimize the production process

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky