Kulicke & Soffa iFlex H1 Pick and place machine

INDUSTRY'S MOST FLEXIBLE ONE-MACHINE CONCEPT

The K&S iFlex is the industry's most flexible modular one-machine concept, available in single-lane or dual-lane. The iFlex machine can be in any combination of any amount of three available modules; scalable in feeder positions, output and/or capabilities, and excels in the four main manufacturing key values, being:

- Quality - Starting at designing the program, until the moment the board leaves the machines, the iFlex uses quality tools and process-driven technologies for the industry's lowest board defect levels of less than 1 dpm!

- Flexibility - Fast in NPI and designed for minimum setup changes and changeovers at batch sizes starting at one PCB - so you can do more jobs a day, and better!

- Efficiency - Technique that is built for constant throughput - for any product, from any job, at any time. Deliver your products always on-time.

- Cost Control - Designed for fast and modular maintenance, low in energy and air consumption. The iFlex is about manufacturing green while saving money, too.

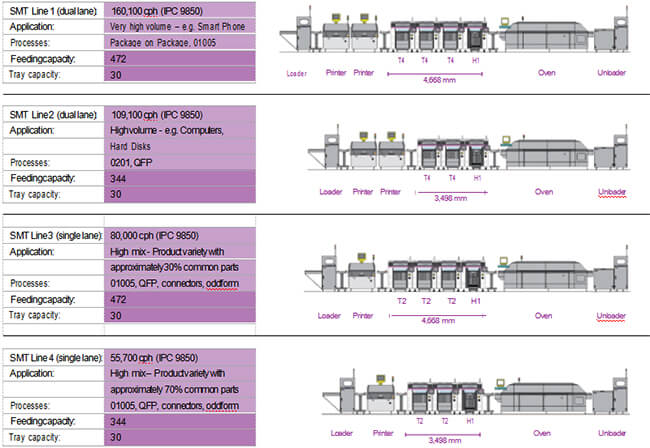

The three available modules are:

- iFlex T4

Chip and IC shooting from 0402M (01005) to 17.5 x 17.5 x 15 mm at 70,000 cph

- iFlex T2

Chip and IC shooting from 0402M (01005) to 45 x 45 x 21 mm at 35,000 cph

- iFlex H1

End-of-line placer placing up to 120 x 52 x 25 mm at 9,000 cph (IPC9850(A))

Options

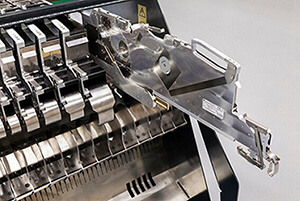

Slim Fit Tape Feeder

The next generation Feeding Platform from K&S

Designed for robustness, low cost of ownership and better pick performance

Main benefits:

Lowest cost of ownership

Ease of use

High performance

Industry 4.0 ready

Flexibility

Improved OEE

Available feeder types:

SF Feeder 4 mm, SF Feeder 8 mm, SF Feeder 12 mm, SF Feeder 16 mm, SF Feeder 24 mm

SF Feeder 32 mm, SF Feeder 44 mm, SF Feeder 56 mm, SF Feeder 72 mm,

SF Feeder 88 mm

SF Feeder platform compatible with AX-501, AX-301, iX502, iX-302 and iFlex

SF Feeder Trolley

Feeder trolleys for fast changeover and setups.

Feeder trolleys come standard with the iFlex . An additional set of trolleys can be obtained for offline setup preparation. Changeovers can be then executed in just minutes.

- Trolley exchange time: Less than 1 minute

- Offline trolley preparation possible with offlinee setup assistant factory software

- Maximum number of feeding lanes: 68

- Tape Cutters: Optional

·

Tray Trolley

Fast exchangeable tray trolley for fast setups. Unique tray caching for high speed tray exchange times.

Unique tray caching concept for the fastest and constant tray exchange times for any application. Trolley concept makes it the ideal solution for high mix production where swapping trays to tape is just a matter of one minute.

- 10 cache positions (for up to 20 Jedec trays)

- 30 storage positions (for up to 60 Jedec Trays)

- Tray exchange on the fly (no production interruption)

- Intelligent, used for traceability and setup verification

- Trolley based. Within one minute exchangeable with standard trolleys or other tray trolley

Stick Feeders

Quick solution for fitting any types of sticks. Feeds via dedicated, generic or custom lanes.

For feeding SMD and small odd form components in stick:

- Dedicated top plates for common stick components (with known EIA outlined dimensions such as SO-IC 8 to PLCC 100).

- Generic top plates. Immediate use of sticks for practically every component type.

- Customized top plates. Customized manufactured top plates for feeding large volumes of (mostly) non-standard components.

Label Feeder

Feeding of pre-printed labels.

For high volume feeding of pre-printed labels:

- Exchangeable label presentation module

- Label sizes up to (LxW) 38 x 50 mm

Carrier Tape Tray

Ideal solution for feeding small pieces of carrier tapes.

Excellent solution in small batch manufacturing where tape components only come as small pieces of tape.

- 8 mm to 200 mm tape strips

- 10 mm deep pockets

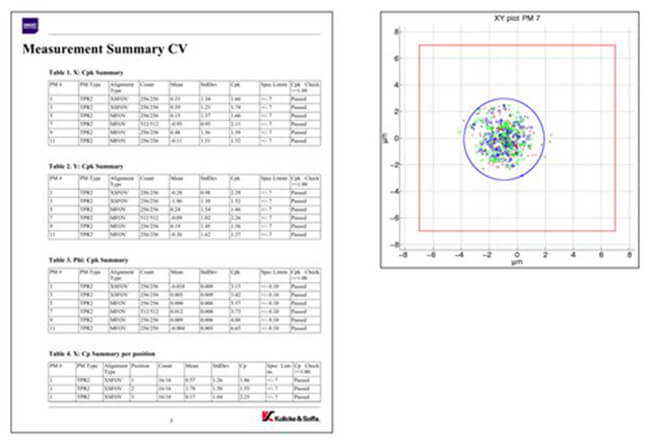

Accuracy Service

Accuracy verification service: measurement, verification and calibration. Including report.

Tools, services and reporting to guarantee placement accuracy, year after year.

- Measurement results per head in CpK

- Automatic placement offset correction

- Offset correction verification Reporting

Feeder Service Shop

Feeder Service Shop

Lower your feeder inventory by controlling feeder maintenance, performance verification, repair and calibration. All at hand in factory for quick return of feeders into production.

| iFlexT4 | iFlexT2 | iFlexH1 | |

| Maximumoutputperhour | 70k | 35k | 9k |

| (51kIPC9850) | (24.3kIPC9850) | (7.1kIPC9850) | |

| PlacementQuality | <1dpm | <1dpm | <1dpm |

| PlacementAccuracyCpk>1 | 40micronforchips | 40micronforchips | 40micronchips |

| 35micronforQFP | 25micronforQFP | ||

| MinimumComponentsize | 0.4x0.2mm(01005) | 0.4x0.2mm(01005) | 0.4x0.2mm(01005) |

| MaximumComponentsize | 17.5x17.5mm(0.69x0.69”) | 45x45mm(1.77x1.77”) | 120x52mm(4.72x2.05”) |

| MaximumComponentheight: | |||

| -Standard | 15mm(0.60”)N/a | 15mm(0.60”)N/a | 25mm(0.98”) |

| -Optional | 35mm(1.38”) | ||

| ProgrammablePlacementForce | 1.5to8N | 1.5to8N | 4.0to30N* |

| Maximumboardsize**: | |||

| -SingleLanestandard | 525x558mm(20.3x21.9”) | 525x558mm(20.3x21.9”) | 525x558mm(20.3x21.9”) |

| -DualLane | 525x254mm(20.3x10”) | 525x254mm(20.3x10”) | 525x254mm(20.3x10”) |

| -DualLaneinSingleLanemode | 525x460mm(20.3x18”) | 525x460mm(20.3x18”) | 525x460mm(20.3x18”) |

| Minimumboardsize: | 50x50mm(2x2”) | 50x50mm(2x2”) | 50x50mm(2x2”) |

| Boardthickness | 0.3to6mm(0.01to0.24”) | 0.3to6mm(0.01to0.24”) | 0.3to6mm(0.01to0.24”) |

| Automatictoolbitexchange | Nozzles | Nozzles | Nozzles,grippers |

| Max.tapefeedingpositions(8mm) | 64singletapes | 64singletapes | 71singletapes |

| 128twintapes | 128twintapes | 142twintapes | |

| Feedingoptions | tape,stick | tape,stick | tape,stick,tray,tubes,others |

| (specialfeedersonrequest) | |||

| DataInterface(s) | CamX | CamX | CamX |

| Footprint(LxW) | 1,170x1,844mm | 1,170x1,844mm | 1,170x1,844mm |

| (46.06x72.60”) | (46.06x72.60”) | (46.06x72.60”) | |

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky