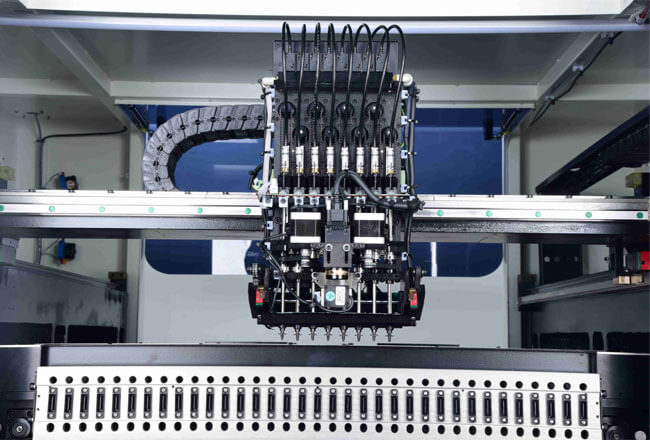

HCT 800L Pick and Place Machine

Product Details

As HCT-800L SMT Pick & Place Machine that equipped with 8 heads as well as a new flying vision system, the HCT-800L realizes a optimum chip mounting speed of 32,000 CPH. In addition, it is applicable to 0201 chips to the largest 30mm ICs by default and increases actual productivity and placement quality by applying a smart nozzle checking and replacing system.

Product Features - Multifunctional Basic LED SMT Pick and Place Machine

1. Vision On the Fly Alignment

2. Bottom Vision Alignment System for big components/IC

3. Fiducial recognition and coordinate correction

4. Three-section conveyor system with SMEMA interface and automatic-width-control

5. Magnetic levitation linear motor in X and Y axis for high repeatability and stability

6. Smart Nozzle System provides automatic nozzle checking and replacing

7. Perfect for medium & high volume production

8. Optimized pick/place routing design, ensures precision and speed

9. Each mounting head has its Z - direction step-servo motor, which is designed for vertical motion

10. Works with different types of high-precision nozzle

11. For different PCB, FPC, MCPCB, PSB, etc.;

Suit for a variety of SMD components: resistors, capacitors, IC, QFP, CFP, etc.

12. Using imported high-precision ball screws, motors, solenoid valves, cables, etc., effectively improves placement accuracy, and stability.

13. Strong and rigid mechanical design

Cleaning of the pick and place machine

If the working environment of the machine is dusty, it will have a quality impact on the installation and welding of small parts and thin pitch (0.3mm) parts such as 0201 and 01005. It also increases wear and tear on equipment and may even lead to equipment failure. Increase the maintenance of the pick and place machine equipment.

In the production environment of the SMT pick and place machine, in addition to dust, there may be some chemical gases around. If there are some harmful substances in these gases, it will cause certain harm to the human body; if these gases are corrosive, it will seriously affect the reliability of the product. Therefore, the working environment must be kept clean, dust-free, corrosive, and odorless gas. This ensures the welding quality of the product, the normal operation of the equipment, and the health of the operators.

Product Display - Multifunctional Basic LED SMT Pick and Place Machine

Technical Parameters

Model

HCT-800L

Number of Heads

Vision on the Fly

8

Placement Rate

Under the optimum condition

32000CPH

IPC9850

26800CPH

Feeder Capacity

Front and Back

35 Tape Feeders

(8mm/12mm Electric Standard)

35+35 Tape Feeders (Optional)

IC Tray Capacity IC

325 x 135mm

2

Component Alignment

Vision Detection

Component Sizes

Handled by Head Camera

Smallest: 0201 (inch)

Largest: 10 x 8 (mm)

Handled by Fixed Bottom Camera

Smallest: 1206 (inch)

Largest: 30 x 30 (mm)

Resolution

X/Y Axis

Magnetic Levitation Linear Motor

Z Axis

Step-Servo Motor

Rotation

0 to 360°

Placement Accuracy

±0.05mm

X-Y Repeatability

Magnetic Grid

±0.002mm

PCB Size

Maximum

L 500 x W 350mm

Minimum

L 50 x W 50mm

In-line Conveyor

3-section Transmit

Programming

Vision Teach-in

Coordinates Import

Main Control

Industrial PC

Power

AC 220V±10% (50/60Hz, 1 phase)

Max. 3.0KW

Air Pressure

0.55-0.7MPa (5.6-7.1kgf/cm2)

Built-in vacuum pump for nozzles

External Dimension(mm) L x W x H

1440*1600*1400MM

Mass

Approximate 1400kgs

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky