HCT 530LV Pick and Place Machine

HCT-530LV Automatic 1.2M LED Pick and Place Machine

The desktop automatic pick and place machine HCT-530LV Automatic 1.2M LED Pick and Place Machine was created with research laboratories and small to medium manufacturing firms in mind, but it may also be used by serious hobbyists. These robotic pick-and-place systems are appropriate for small-batch manufacturing, in-lab product testing, research and development, LED SMT assembly, and other related procedures.

Product Features - Automatic 1.2M LED Pick and Place Machine

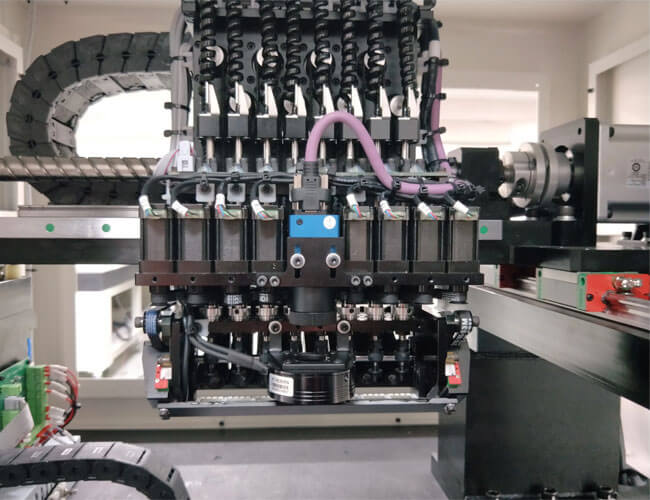

1. High accuracy: Each of the eight pick-up heads is equipped with a FLYING vision alignment camera to guarantee high accuracy.

2. High-speed: Maximum placement speed reaching 0.086s/chip.

Each mounting head has its Z - direction closed-loop stepper motor, which is designed for vertical motion.

3. Places SMD components from 0603 to 7474, including resistors, capacitors, and standard and irregularly shaped LEDs.

4. Suitable for all LED lighting products, including flexible PCB strips, circular LED light bulb boards, and even irregularly shaped boards. Assembles LED PCBs up to 1.2 meters long in a single pass.

5. With a SMEMA-compatible inline conveyor for line automation.

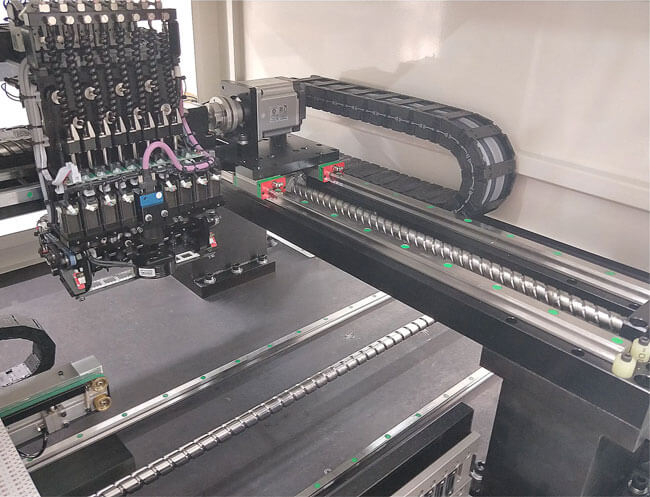

6. Heavy marble platform support to ensure long service life.

7. Excellent quality hardware support by using international famous brands ensures placement repeatability and precision.

8. Self-developed software simplifies production, easy to operate and program.

HCT-530LV Automatic 1.2M LED Pick and Place Machine is a desktop automatic pick and place machine specially developed for research laboratories and small and medium manufacturing enterprises however it will also be suitable for the serious hobbyist. These automatic pick-and-place machines are suitable for small batch production, laboratory research and development, product sample trials, LED SMT processing, and other similar processes.

Product Display - Wholesale Automatic Pick And Place Machine

Technical Parameters

|

Model |

HCT-530LV |

|

|

Alignment |

Flying Vision Alignment System |

|

|

Number of Spindles |

8 Spindles x 1 Gantry |

|

|

Rated Placement Speed |

Vision Alignment |

LED 2835 45,000 CPH (Optimum) |

|

Placement Accuracy |

±0.05mm (Based on the standard chips) |

|

|

Mechanical Precision |

±0.02mm |

|

|

Component Range |

VisionAlignment |

0603(inch)~5050~7474(mm), |

|

high-power LED,IC<10mm |

||

|

Max Height |

H=10mm (can handle max. 16mm without vision alignment) |

|

|

Board Dimension (mm) |

Maximum |

1,200(L) x360(W) |

|

Board Handling Method |

Inline Conveyor |

|

|

Tape Feeder |

Feeder Type |

Electric Feeder |

|

Feeder Capacity |

20 (12mm) |

|

|

Optional |

8mm, 12mm, 16mm, 24mm |

|

|

Utility |

Power |

AC 220V/240V 50/60Hz, Single phase |

|

Max2.8KW |

||

|

AirSupply |

0.55-0.7MPa (5.6-7.1kgf/cm2) |

|

|

Built-in Vacuum Pump for Heads |

||

|

Mass |

Approx.1560kg |

|

|

External Dimension(mm) |

2,000(L) x1,250(D) x 1,400(H) |

|

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky