Axxon Mycronic MYC50 Coating Machines

The MYC50 is ready to perform automated complex coating processes, monitor process parameters and can switch coating patterns without interruption. Our Coating platform gives you powerful, software-driven process flows that ensure years of productivity for even the most complex PCBs.

Product Features

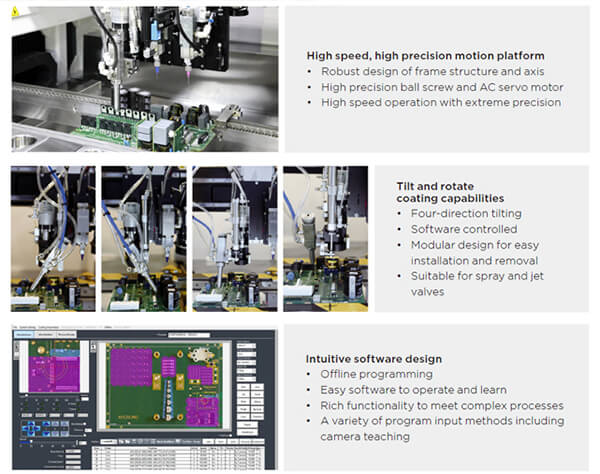

As electronics continually become embedded into an endless variety of products, the need for high-precision conformal coating is greater than ever before. The MYSmart MYC50 inline conformal coating platform combines high-accuracy edge definition with advanced feedback systems. A wide range of process parameters can be monitored, enabling high-quality output. There are many options for process control optimizations: fan width control, flow monitoring, heated fluid systems and bar code readers. Wherever ruggedized electronics are required, the MYC50 minimizes material waste while ensuring a controlled layer thickness over the complete coated area.

APPLICATIONS

• Consumer electronics

• Industrial electronics

• Household appliances

• Automotive control panels

• Military electronics

• Computer control panels

• Agricultural equipment control panels

• Battery protection boards

• LED lighting

• Outdoor led displays

• Converter circuit boards

• Security control panels

• Motor control boards

• Power management devices

Specifications

| MOTION SYSTEM | |

| X-/Y-AXIS | Z-AXIS |

| Speed: max 800 mm/s | Speed: max 300 mm/s |

| Acceleration: max (0.8 g peak with s-curves) | Acceleration: max (0.3 g peak with s-curves) |

| Repeatability: ±25 um, 3σ | Repeatability: ±25 um, 3σ |

| Drive mode: servo motor, ball screw | Drive mode: servo motor, ball screw |

| FOUR DIRECTION TILTING MODULE | |

| Rotation angle: 0 degree, 90 degrees | Tilt angle: 0 degree, ± 35 degrees(Manually adjust other degrees) |

| Repeatability: ± 0.1 degree | Repeatability: ± 0.1 degree |

| Drive mode: cylinder | Drive mode: cylinder |

| DISPENSING AREA | |

| ONE WORK STATION(XxY) | TWO WORK STATIONS(XxY) |

| Single valve max: 650 x 450mm | Single valve max: 450 x 430mm |

| Asynchronous dual valve max: 550 x 410mm | Asynchronous dual valve max: 450 x 410 mm |

| Asynchronous dual valve with four direction tilting | Asynchronous dual valve with four direction tilting |

| module max: 540 x 360mm | module max: 450 x 360mm |

| Asynchronous tri-valve max: 475 x 380 mm | Asynchronous tri-valve max: 450 x 380mm |

| Max clearance PCB: top 100mm, bottom 100mm | Max clearance PCB: top 100mm, bottom 100mm |

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky