Assembleon MG-1 Pick and place machine

Specifications:

Optimal output per hour: 24,000

IPC-9850 output per hour: 17,400

Placing accuracy at 3 Sigma: 30 micron

Alignment principle: Line array

Footprint (L x W): 1650 x 1562 mm

Min. component size: 01005

Max. component size: 45 x 100 mm

Max. component height: 15 mm

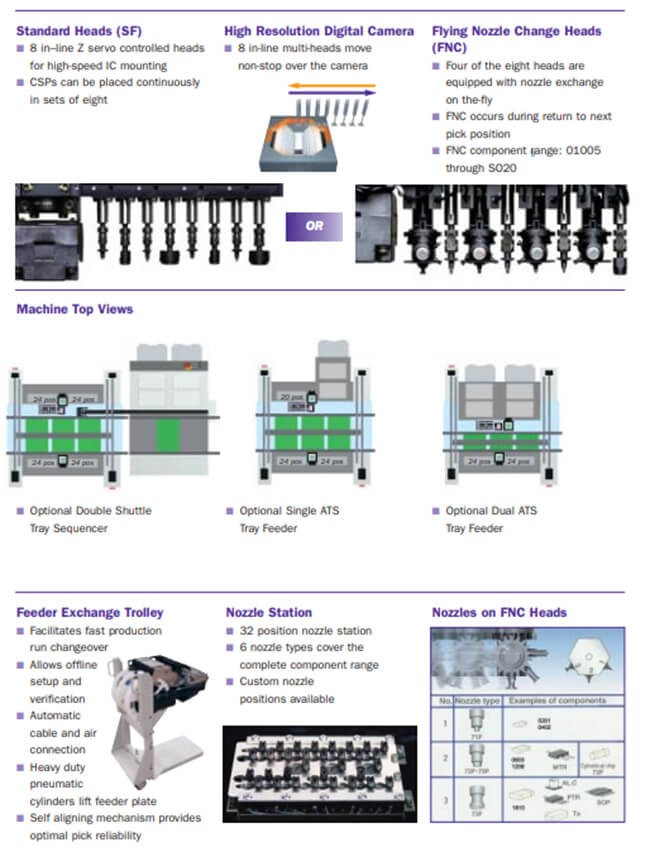

Nozzle exchange automatic and on-the-fly for MG-1 FNC

nozzle exchange Nozzle exchange automatic for MG-1 SF nozzle exchange

Min. board size (L x W): 50 x 50 mm

Max. board size (L x W): 460 x 440 mm

Optional board size (L x W): 570 x 500 mm Board thickness 0.4 to 4.0 mm

Tape feeding positions (8 mm): 96

Other feeder options: tape, stick, tray options tube, waffle pack, etc

Feeder trolleys: tape feeder trolley

| MG-1 (NC) | MG-1 (SF) | |

| Tact time: | 0.15 sec/chip with line array camera 0.30 sec/SO with line array camera 0.8 sec/QFP with line array camera | Simultaneous pick with 8 heads Simultaneous pick with 4 heads Sequential pick with 4 heads |

| Optimal placement rate: | 24,000 chip | Simultaneous pick with 8 heads |

| Tact time IPC 9850: | 17,400 chip | C0603; all heads, all angles |

| Nominal placement rate: | 14,000 - 16,000 chip | Real mounting speed |

| Applicable Components: | 01005 - SOP, SOJ, PLCC 32mm (1.26") 01005 - 20mm (0.79") with pin pitch down to 0.3mm (12 mil) 20mm - 32mm (0.79") with pin pitch down to 0.4mm (16 mil) BGA, μ BGA,CSP : 32mm ☆ Min. ball pitch down to 0.4mm (16mil) Min. ball diameter down to 0.1mm (4mil) Irregularly shaped SMDs, 100mm x 32mm Maximum grid for BGA components is 64x64 | Line array camera system (32mm) Ball pressure check for ≥ 0.1mm ball diameter Ball defect check for ≥ 0.2mm ball diameter |

| 0201 - SOP, SOJ, PLCC 45mm ☆ (1.77") 0201 - 20mm (0.79") with pin pitch down to 0.4mm (16 mil) 20mm - 45mm ☆ (1.77") with pin pitch down to 0.5mm (20 mil) BGA, μ BGA,CSP : 45mm ☆ Min. ball pitch down to 0.4mm (16mil) Min. ball diameter down to 0.15mm (6mil) Irregularly shaped SMDs, 100mm x 45mm | Line array camera system (45mm) Ball pressure check for ≥ 0.1mm ball diameter. Ball defect check for ≥ 0.2mm ball diameter | |

| Maximum grid for BGA components is 64x64 | ||

| Component height: | Max: 15mm | Max: 15 mm |

| Mounting accuracy (X,Y) μ = 3σ: | ± 50μ for chips 01005-0201-0402 ± 75μ for chips and SOIC (this is lead dependent) ± 30μ for QFPs | Line array camera system (all placement heads and all placement angles, with special components and board) |

| Mounting accuracy (φ) 3σ: | For Chips and SOIC (Lead dependent) ±0.1° for QFPs | Line array camera system (all placement heads and all placement angles) |

| Mounting repeatability X,Y 3σ: | 15μ for QFPs | |

| Mounting angle: | 0 up to 360 (programmable in steps of 0.01) |

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky