ALEADER ALD6700S 2D and 3D SPI Machine

Simultaneous 2D and 3D inspection guarantees full inspection coverage with the most accurate measurement of height, area and volume of the paste deposits

Excellent – high resolution image, generated by the high speed camera and the unique lighting system, clearly differentiate the pastes, pads, silkscreen and the board.

Innovative – automatic warpage compensation and measurement floor recognition method based on the color filter. Effective combination of the high quality color 2D image and large 3D measurement range allows an easy identification of the pads as a zero level for the paste height measurement. The method completely eliminates influence of the PCB warpage. The process is completely automatic and no actions from user are required.

Precise – height measurement based on Phase Measurement Profilometry (PMP). Bi-directional phase shifting projection system ensures accurate and noise resistant measurement of the paste height and volume.

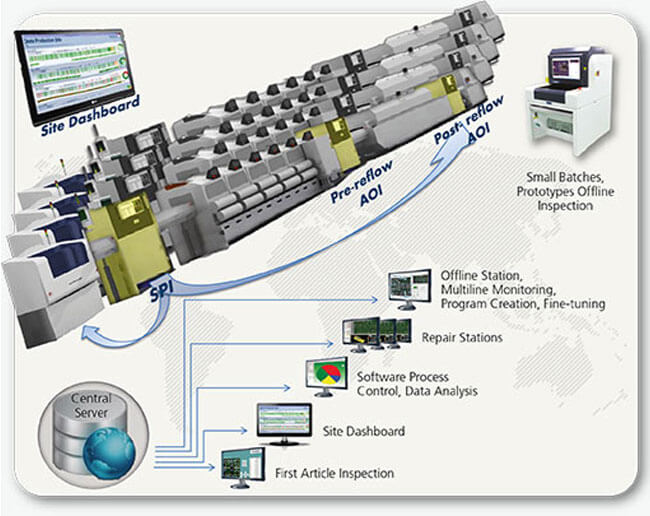

Optical Inspection Solutions

Simultaneous 2D and 3D inspection guarantees full inspection coverage with the most accurate measurement of height, area and volume of the paste deposits

Our Optical Inspection Solutions Consist:

Excellent – high resolution image, generated by the high speed camera and the unique lighting system, clearly differentiate the pastes, pads, silkscreen and the board.

Innovative – automatic warpage compensation and measurement floor recognition method based on the color filter. Effective combination of the high quality color 2D image and large 3D measurement range allows an easy identification of the pads as a zero level for the paste height measurement. The method completely eliminates influence of the PCB warpage. The process is completely automatic and no actions from user are required.

Precise – height measurement based on Phase Measurement Profilometry (PMP). Bi-directional phase shifting projection system ensures accurate and noise resistant measurement of the paste height and volume.

SMT Inspection Equipment Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky