ERSA EXOS 10/26 Reflow Soldering Machine

Ersa answers the demands of electronics manufacturing for pore-free solder joints - especially for power electronics and high-reliability technology - with the EXOS 10/26, a convection reflow soldering system with 22 heating chambers and 4 cooling zones as well as a vacuum chamber after the peak zone, which can reduce the void rate by an impressive 99%. Thanks to intelligent features, the EXOS 10/26 can produce particularly economically and "void-free".

Technology Highlights Reflow Soldering System EXOS 10/26

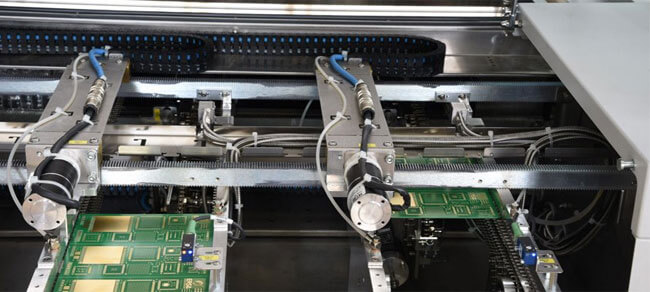

4-part conveyor (infeed, preheating and peak, vacuum, cooling zone) also as dual track

Perfect synchronization of the assemblies and transitions thanks to sensor-monitored conveyor, no external infeed module required

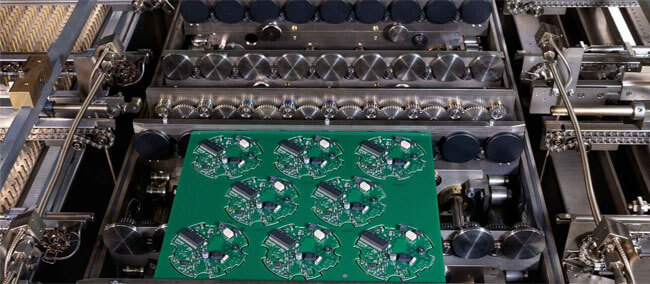

Maintenance-friendly and lubricant-free roller conveyor in the vacuum module

Optimum access to the vacuum chamber through lifting unit from above

Optimum temperature profiles through medium-wave emitters in the vacuum module

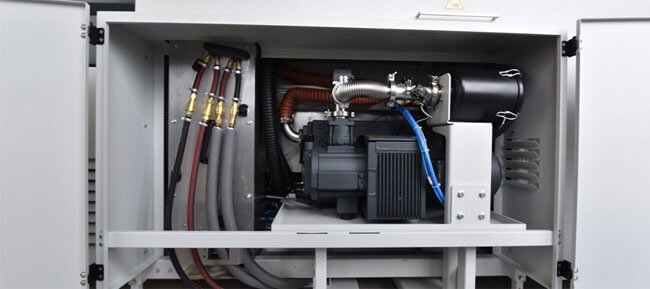

Maximum machine availability thanks to fast removal of the conveyor unit in the vacuum module

Part-integrated vacuum pump on separate module carrier for easy and fast maintenance

Innovative cleaning system SMART ELEMENTS®

EXOS 10/26: Safe processes, maximum throughput - minimum footprint thanks to innovative transport system

EXOS 10/26: Roller transport - highest assembly quality and machine availability

EXOS 10/26: Medium-wave emitters - optimum temperature profiles with vacuum process

EXOS 10/26: Vacuum module - maximum safety and ease of maintenance

Technical data Ersa Reflow Soldering System EXOS 10/26

| Dimensions | |

| Length | 7,875 mm |

| Height | 1,969 mm |

| Width | 2,195 mm |

| Weight with options | 5,000 kg |

| Conveyor system | |

| Working width | 50-630 mm |

| Transport speed | 20-200 cm/min |

| Working width (centre support) | 100-630 mm |

| Transport over ground | 820-980 mm |

| Throughput height | +/-35 mm |

| Pin chain transpor | 5 mm overlay |

| Centre support, strap height | 11 mm |

| Heating system | |

| Convection rate (except vacuum chamber) | 100% |

| Soldering zone | 2 top/2 bottom |

| Volumetric flow/module | 500 m3/h adjustable, Multijet |

| Nominal power/modul | 3,3/4,5/9,0 kW |

| Convection heating modules | 11 top/11 bottom |

| Heating system vacuum chamber | 2x regulated (4,8/6,8 kW) |

| Preheating | 9 top/9 bottom |

| 3 medium wave heaters | 1x set (4 kW) |

| Vacuum chamber | |

| Chamber volum | approx. 110 l |

| Ultimate pressure | up to 10 mbar |

| Pump capacity | up to 240 m3/h or 5,3 kW |

| Electrical data | |

| Voltage | 5-wire network, 3x 400 V, N, PE |

| Nominal power | 118-150 W |

| Voltage tolerance | +/-10% |

| Power reduced | 55 kW |

| Frequency | 50/60 Hz |

| Continuous power in operation | approx. 14-25 kW |

| max. back-up fuxe | 3x 100 A |

| Exhaust | |

| Exhaust nozzle | 2 pieces, each 150 mm (diameter) |

| Exhaust air monitoring per nozzle | |

| Extraction capacity per nozzle | 400 m3/h |

Jacky

Jacky Jacky

Jacky