FUJI ALMEX-R Pick and place machinec

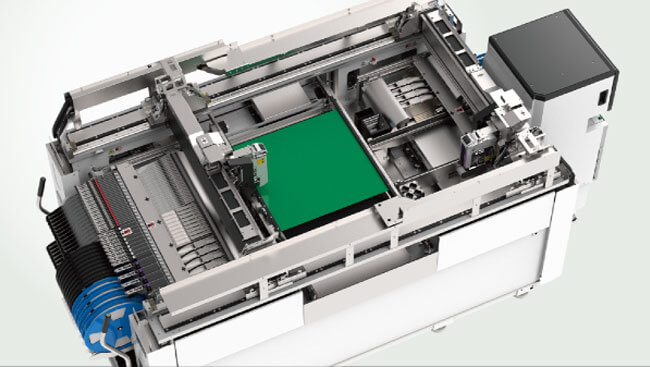

This high-end model is equipped with the latest functions to provide flexibility and adaptability to a variety of production needs.

This flexibility is demonstrated with features such as NPI support for rapid launch of new production and immediate response to changes in production needs through batch changeover. The AIMEXR inherits the versatility that is a staple of the AIMEX series, such as high productivity, high quality, and mass production. It enhances the exiting platform through new sensing functions.

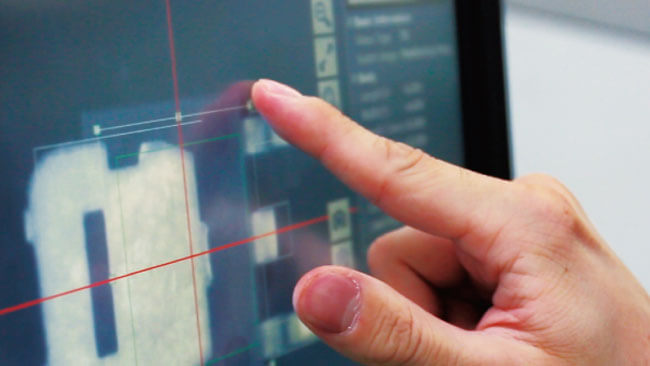

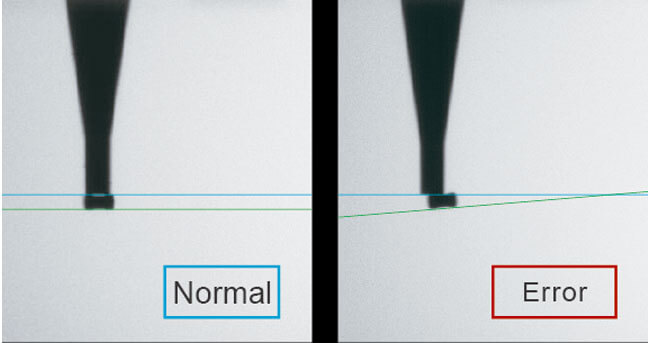

The system uses real-time sensing technology to monitor the condition of electronic parts and panels during operation. This data is instantly analyzed and applied to ensure precise placement, maintaining consistent and reliable quality.

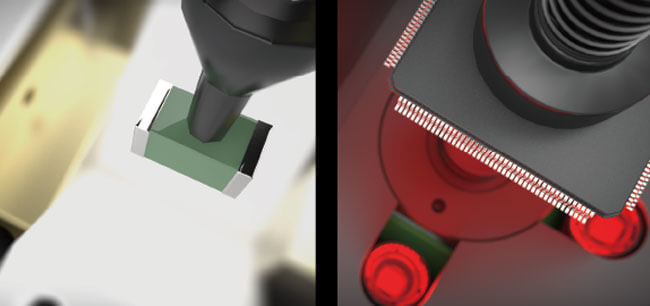

The IPS system can perform a variety of checks, including part pickup position, parts remaining on nozzles, and upside-down checks for minimold parts. It helps prevent placement defects caused by packaging issues, nozzle problems, or part irregularities.

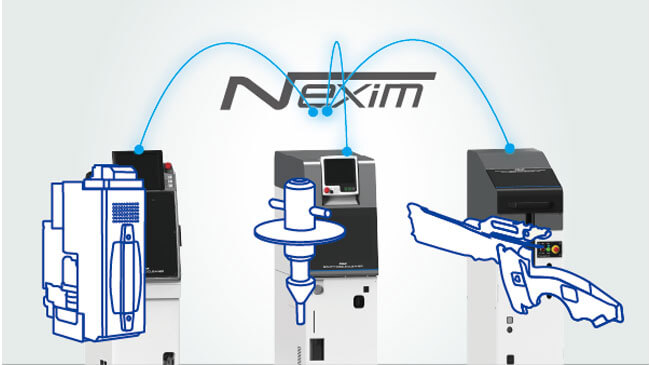

Nozzles, feeders, and heads can all be maintained offline. Automation units ensure reliable maintenance without the need for specialized skills, and connecting these units to Nexim enhances overall maintenance management.

Features

Expanded Capacity

Despite its compact size, the AIMEXR offers extensive capacity, enabling flexible and diverse production operations.

Placement Heads

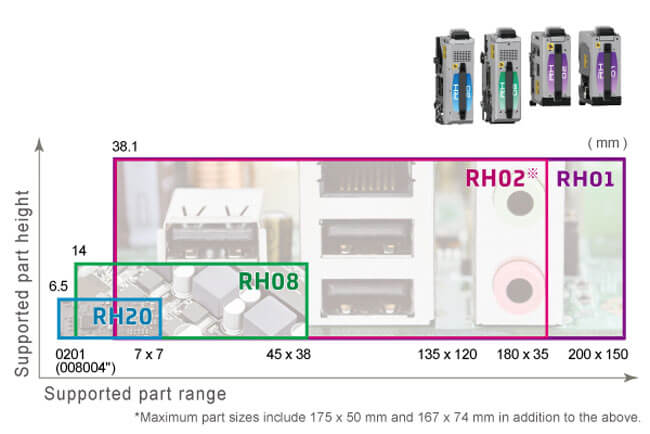

The AIMEXR utilizes the same advanced heads as the NXTR, offering exceptional versatility. These heads expand the range of compatible parts, enabling seamless line balancing and ensuring consistent production rates, even when transitioning to a new set of parts for the next production run.

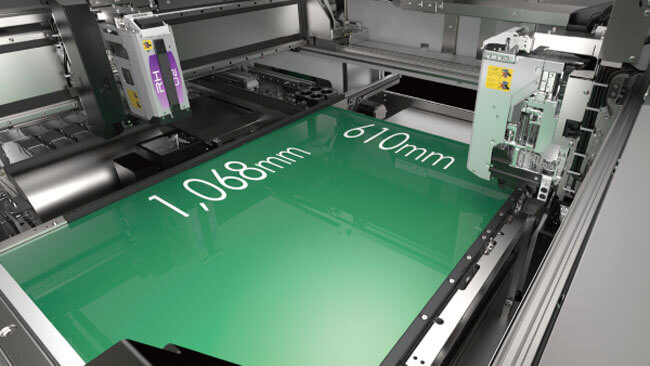

Greater Support for Large Panels

The AIMEXR can handle panels up to a maximum size of 1,068 x 610 mm, making it suitable for a wide range of applications. These include LED placement, automotive panels, and large panels used in communication infrastructure

Minimize Changeover

The machine features large-capacity part supply units capable of holding up to 130 different part types. This design enables shared setups, reducing the frequency of changeovers and easing operator workloads.

Full Production

The machine allows immediate program adjustments to address sudden production changes or vision processing errors during operation. These on-machine editing capabilities help minimize downtime and reduce the lead time required to resume or ramp up production.

High Quality Placement

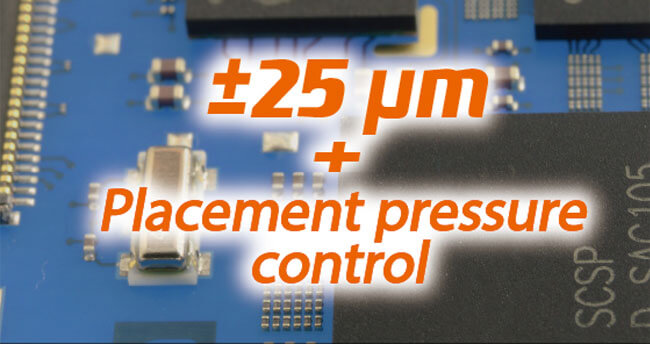

High Accuracy Placement

Placements are made with a high accuracy of ±25 µm, regardless of the head type or part being placed. It also carefully regulates the push-in pressure during placement to ensure optimal precision and reliability.

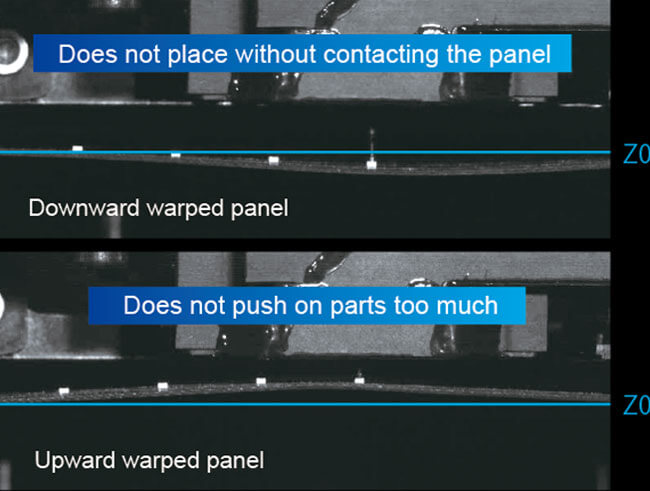

Panel Warpage Adjustment

Reliable placement is ensured by detecting and compensating for panel warpage and variations in individual parts using advanced features. This maintains productivity, even with large panels that are prone to significant warping (up to 7 mm).

Defect Detection (IPS System)

Preventing Defects via Part Properties

Placement defects caused by operational errors or defective parts are prevented by performing LCR checks on the electrical properties of chip parts and coplanarity checks on the leads and bumps of IC parts. (Option)

Fastest in the Series

It achieves the fastest placement speed in the series’ history by utilizing advanced XY robots with linear motors, leading to significant improvements in area productivity.

Stable Operation & Non-Stop Production

The system supports continuous production with quick recovery, helping to minimize downtime and improve overall operation rates.

Maintenance

SMT Pick and place machine Brand

Efficient Technology Co.,Ltd provide a full SMT assembly line solutions, including SMT Production Line, SMT Pick and place machine, SMT Stencil Printer, SMT Inspection equipment, SMT Weling equipment, SMT Intelligent Storage System, SMT Automatic Insertion Machine, SMT Peripheral Equipment, SMT Feeders, SMT Nozzles, SMT Spare Parts etc any kind SMT machines you may need, please contact us for more information: WeChat: +8613714564591 Email: sales@efsmt.com

FAQ:

Q: What we can do for you?

A: One-stop SMT Solution Supplier; Reliable SMT Partner.

Q.What is your MOQ requirement for the machine?

A. 1 set moq requirement for the machine.

Q. This is the first i use this kind of machine, is it easy to operate?

A: Provide free training,There are also English manuals or instructional videos to show you how to use the machine.

Q: If the machine has any problem after we receive it, how can we do?

A: Our engineer will help to solve it first, and free parts send to you in machine warranty period.

Q: Do you provide any warranty for the machine?

A: Yes 1 year warranty will be provided for the machine.

Q: What is your payment terms?

A: 30% deposit in advance and 70% balance before shipment.

Jacky

Jacky Jacky

Jacky